Vistaprint Packaging Tape - Adhesive Tape, Stationery Glue, BOPP Adhesive Tape, Masking Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application:

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

REMARKS:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

TAPE FAQ

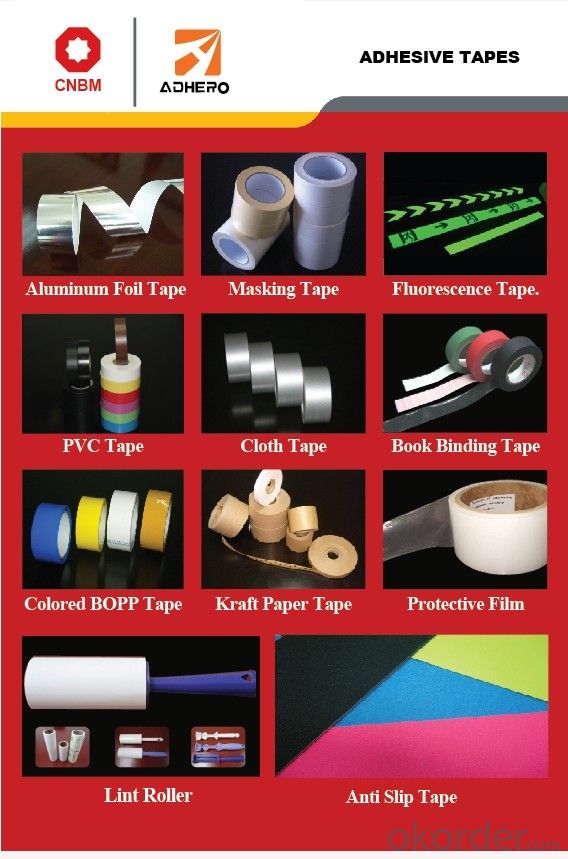

What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

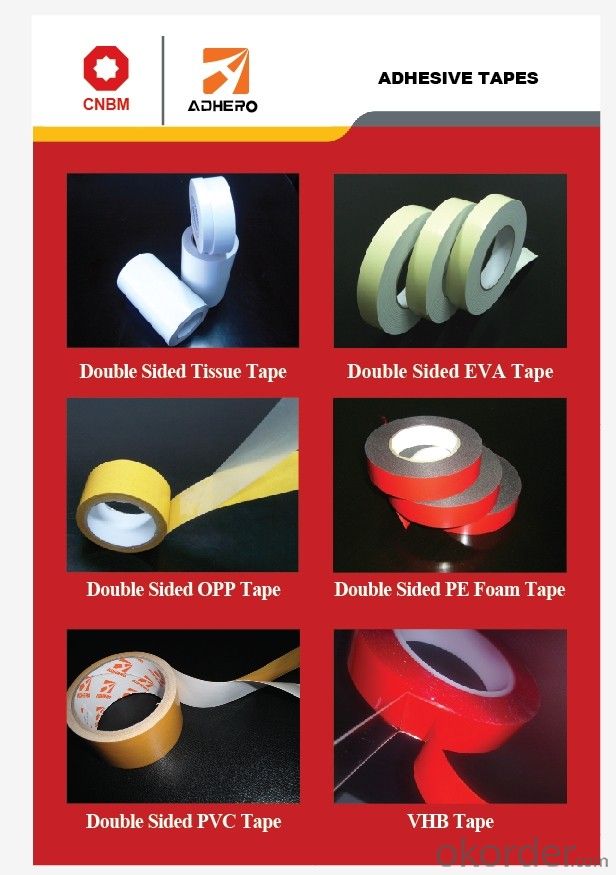

How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

What are the international commodity codes for these products?

HS Code: 48231900.

Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand. Most packaging tapes are designed with a serrated edge or perforation, making it easy to tear off a desired length without the need for scissors or any other tools. This feature allows for quick and convenient packaging and sealing of boxes or packages without any hassle. However, it is important to note that the ease of tearing may vary depending on the brand and quality of the packaging tape.

- Q: Can packaging tape be used for sealing plastic bottles?

- Indeed, the utilization of packaging tape in sealing plastic bottles is possible. Designed with the purpose of providing a secure and tight seal on various surfaces, including plastic, packaging tape boasts robust adhesion. Consequently, it effectively ensures the security and protection of the bottle's contents. Nevertheless, it is crucial to acknowledge that packaging tape may not match the efficacy of specialized bottle sealing alternatives like bottle caps or seals. These alternatives are exclusively crafted for plastic bottles and offer a more dependable and leak-proof seal. Consequently, although packaging tape can serve as a temporary solution, it is advisable to employ proper bottle sealing options for the long-term storage or transportation of liquids.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Certainly, packaging tape is suitable for sealing packages that contain jewelry or valuable items. Its purpose is to create a strong and long-lasting seal, making it an ideal option for guaranteeing the safety of your valuable possessions during shipping or transportation. Its strength and adhesive properties ensure a secure closure, safeguarding the contents within. Nevertheless, it is advisable to take extra precautions when shipping valuable items, such as utilizing bubble wrap or cushioning materials in order to provide an additional layer of protection.

- Q: What are the different types of packaging tape?

- For various packaging needs, one can find several types of packaging tape. 1. Clear Packaging Tape: The most commonly used packaging tape is clear. It is typically made from polypropylene or acrylic materials and is transparent, enabling easy visibility of labels or printed information on the package. Clear packaging tape is versatile and suitable for most general packaging applications. 2. Brown Packaging Tape: Another type of packaging tape is brown. It is also known as brown packing tape or brown carton sealing tape. This tape is made from strong and durable materials like polypropylene or paper. It is commonly used for sealing cardboard boxes or packages, providing a secure and tamper-evident seal. Brown packaging tape is ideal for shipping and general packaging purposes. 3. Masking Tape: Although not specifically designed for packaging, masking tape can be used for light-duty packaging tasks. It is made from thin and easily tearable paper. Masking tape is commonly used for holding, bundling, or labeling packages. However, it may not provide the same level of strength and security as dedicated packaging tapes. 4. Duct Tape: Similar to masking tape, duct tape is not primarily intended for packaging purposes but can be used in specific situations. It is a strong and durable tape, typically made from cloth or reinforced with fibers. Duct tape is known for its adhesive strength and versatility. It can be used for heavy-duty packaging tasks or for securing packages in challenging environments. 5. Specialty Packaging Tapes: There are various specialty packaging tapes available to cater to specific needs. Examples include fragile tape, which has a warning message to indicate delicate items inside the package, and double-sided tape, which allows for secure attachment of items or joining of materials. Additionally, there are tapes designed for specific industries, such as freezer tape for sealing packages in cold storage or electrical tape for insulating electrical wires during packaging. In conclusion, the choice of packaging tape depends on the specific requirements of the packaging task, including the type of materials being sealed, the desired level of security, and any specific conditions or considerations.

- Q: Are there different colors of packaging tape?

- Yes, there are different colors of packaging tape available.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape does come in different allergen-free options. Many manufacturers offer packaging tape that is specifically designed to be hypoallergenic and free from common allergens such as latex, gluten, and other potential irritants. These allergen-free options are particularly beneficial for individuals with sensitive skin or allergies. It is always recommended to carefully read the product labels or descriptions to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: Can packaging tape be used for sealing packages with fragile artwork or sculptures?

- Yes, packaging tape can be used for sealing packages with fragile artwork or sculptures. However, it is recommended to use additional protective materials such as bubble wrap or foam to provide cushioning and ensure the safe transportation of delicate items.

- Q: Can packaging tape be used for sealing medical or pharmaceutical supplies?

- No, packaging tape is not suitable for sealing medical or pharmaceutical supplies as it may not provide an adequate barrier against contamination or tampering. Specialized medical or pharmaceutical grade sealing materials should be used for these purposes.

- Q: Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

- Q: I'd like to know the specifications of the sealing tape. How do you see it? (the following two examples) product name: sealing tape product type: 2.5 inch product specifications: 57mm*80 code (8.5mm thick) weight: about 0.145KG the price for volume: Specifications: code number 48mm*150 meters *40u flesh 20mm here refers to what? I know that 40U means stickiness, so how do I see that?

- As for the latter 40 mu m (micron), not refers to viscous, but refers to BOPP original film + adhesive layer of the total thickness, that is, the thickness of the tape.

Send your message to us

Vistaprint Packaging Tape - Adhesive Tape, Stationery Glue, BOPP Adhesive Tape, Masking Tape

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords