Ductile Iron Manhole Cover C250 D400 for Construction EN124

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

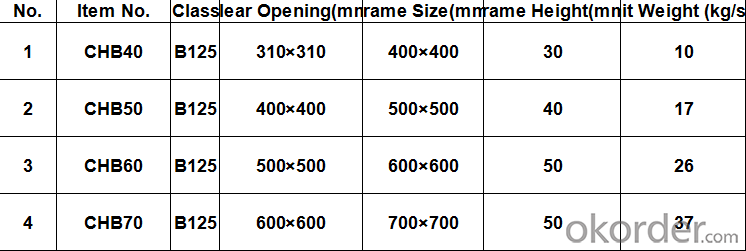

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found.

- Q: Where is the precision casting factory?

- Everywhere is. Look what you want to do

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

Send your message to us

Ductile Iron Manhole Cover C250 D400 for Construction EN124

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords