ductile iron manhole cover and drain grating manhole cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 230 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

2.Designs: based on EN124 standard and according to customer's drawing or samples.

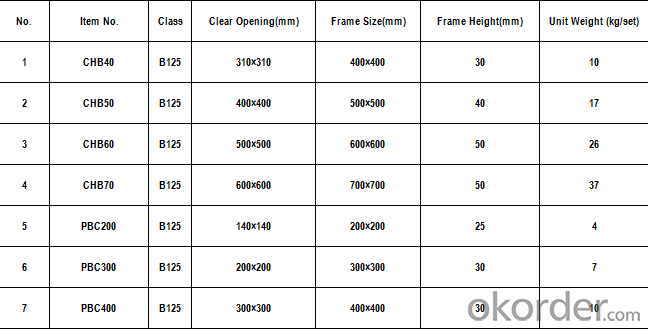

Specifications:

Packaging & Delivery:

1.Packaging Details: Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 8 days if your order is 20"container

Features:

1.Higher quality /higher tensile

2.Higher security /long life

3.Possibilities of new locking systems

4. Good compressive, bending and impact strength,anti-corrosion, not rust, long service life (at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery.

E. Good after sales service.

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air.

B. Less than one container you can choose LCL shipment by sea.

C. One container or more than one container you can choose FCL shipment by sea.

4.Could you specially design and produce for clients?

A: Sure, we have all kinds of professional engineers.We can design and produce special products according to customers' request. Such as: special size, special control, OEM, etc.

5. What’s the MIDAS main market?

A: Our main market is African, Middle East Countries, South American, Asian.

Pictures:

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- Yes, the cast aluminium is polarized and gray, but the key problem is to guarantee the quality of the aluminium casting, and the quality of the other aluminium casting is not good.

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- It has something to do with the size of your work, and it has a lot to do with the blade you're using right now.

Send your message to us

ductile iron manhole cover and drain grating manhole cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 230 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords