Drive Pump, Fluorine Plastic Magnetic Drive Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION:

Fluorine plastic magnetic drive pump canceled the seal by magnetic coupling indirect drive, completely eliminating the drip causing no pollution venues.

Because the pump flow part of the selection of fluorine plastic alloy, continuous transport any concentration of acid and strong oxidizing agents and other corrosive media without damage

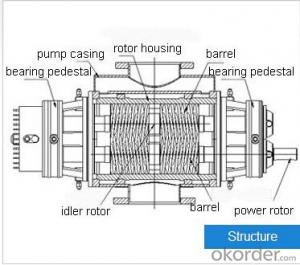

Working principle

Drive with active magnetic coupling directly mounted on the motor shaft, the pump chamber is completely enclosed by a magnetic coupling indirect drive with a magnet on the impeller shaft rotation, compact structure, safety and energy conservation.

Rugged pump structure

Although the contact with the liquid part of the fluorine plastic, but the pump casing is metal, so the pump enough to withstand the weight of the pipe and withstand the mechanical impact

The main purpose

The products are widely used: petroleum chemical acid and alkali non-ferrous metal smelting automobile manufacturing pickling process rare earth separation pesticide dye paper plating radio pharmaceuticals and other industries

Operating temperature: -20 ℃ -100 ℃

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Send your message to us

Drive Pump, Fluorine Plastic Magnetic Drive Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords