DN125 90D 45D 30D Single Wall Concrete Pump Elbow

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Material | Specification | Weight | Common life time | Life tine for two end parts | Max work pressure |

Normal bend | ZG40Mn2 | DN125R27590° | 16kgs | 6000-8000m³ | 1000-3000m³ | 126 bar |

Wear-resistant bend | Mn13-4 | DN125R27590° | 16.5kgs | 20000-25000m³ | 2000-7000m³ | 132 bar |

Twin wall bend | Cr20NiCu1Mo+G20 | DN125R27590° | 15kgs | 60000-80000m³ | 20000-30000m³ | 91 bar |

Twin wall bend | GX350+G20 | DN125R27590° | 15kgs | 80000-150000m³ | 40000-50000m³ | 98 bar |

Product Specifications Model:

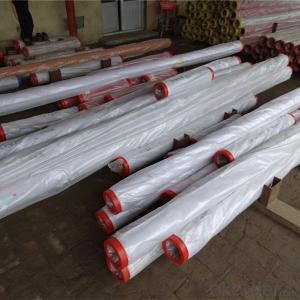

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts for 10 years and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: is it the first overall drawing, or first out parts drawings, and then assembly?

- Take out the part drawings first and then assemble them into a whole picture

- Q: What are the basic requirements for the design of mechanical parts?

- In order to improve the strength of mechanical parts, the following measures can be adopted in principle at design time:Adopt a material of high strength;Make the part have enough sectional size;The sectional shape of a part is properly designed to increase the moment of inertia of the cross section;The mechanical properties of the material were improved by heat treatment and chemical heat treatment;Improve the manufacturing accuracy of moving parts to reduce the dynamic load at work;Reasonable allocation of parts of the machine in order to reduce the impact on the parts of the load.

- Q: Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q: Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- A part of an assembly drawing. If it is a standard part, fill in the name of the part and the standard code. If it is a nonstandard part, fill in the part name and the code specified by the company.As you mentioned, it should be the standard staff who can only fill out the part code, which is the code number specified by your company. Drawing design, the non-standard parts using the company's parts code.

- Q: I'm going to learn 3D design. I used to just CAD.Excuse me, is it good to learn PRO-E or SOLIDWORK?I mainly used in product design (such as sheet metal parts, machining parts and plastic parts, etc.) is used to design the mould.Also, you can download the best Chinese version of these two software from the Internet, please ask friends about the locationUrgently...

- These two can, there is a director, according to the domestic general situation, usually PROE use more, exchange more convenient, as long as there is a three-dimensional software with skilled, no matter that can be.

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- When the metal material reaches its yield limit, the plastic deformation still goes on without increasing the external force. The general mechanical parts (flanges, elbows) and engineering structural parts are not allowed to produce plastic deformation, otherwise it will fail and accidents. Therefore, the design of mechanical parts (flanges and elbows) mostly takes the yield limit as the design.

- Q: Fixture assembly drawings, detailed parts drawings, design instructions, machining processes, integrated cards, and process cards will be added

- This is not difficult, the machining process card, machining process card, as well as fixture design can do it, learning tyrants have done a lot of experience, you can communicate

- Q: How to write the machining process design of machine parts?

- According to each process that the part needs to be processed, the processing technique is determined.

- Q: Are there any standards or specifications for the design of parts list in mechanical design?

- Each company's specifications are not the same, but the general processing parts must have part name, parts drawing number, quantity, material / heat treatment methods (surface treatment methods), remarks, etc.. If purchased, it includes name, model, brand, requirement, remark and so on

- Q: Mechanical design, hardness of the workpiece, how to determine, for example, in the drawings, technical requirements of the hardness value how to get?

- If you are engaged in a kind of graduation design, go to the library and borrow some of the heavy tools for your design manual, mechanical, can get the corresponding information in the manual, manual information can be used as the basis,

Send your message to us

DN125 90D 45D 30D Single Wall Concrete Pump Elbow

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches