Discount Packaging Tape for Plastic Film Masking in Auto Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Plastic Film For Masking In Auto Industry

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

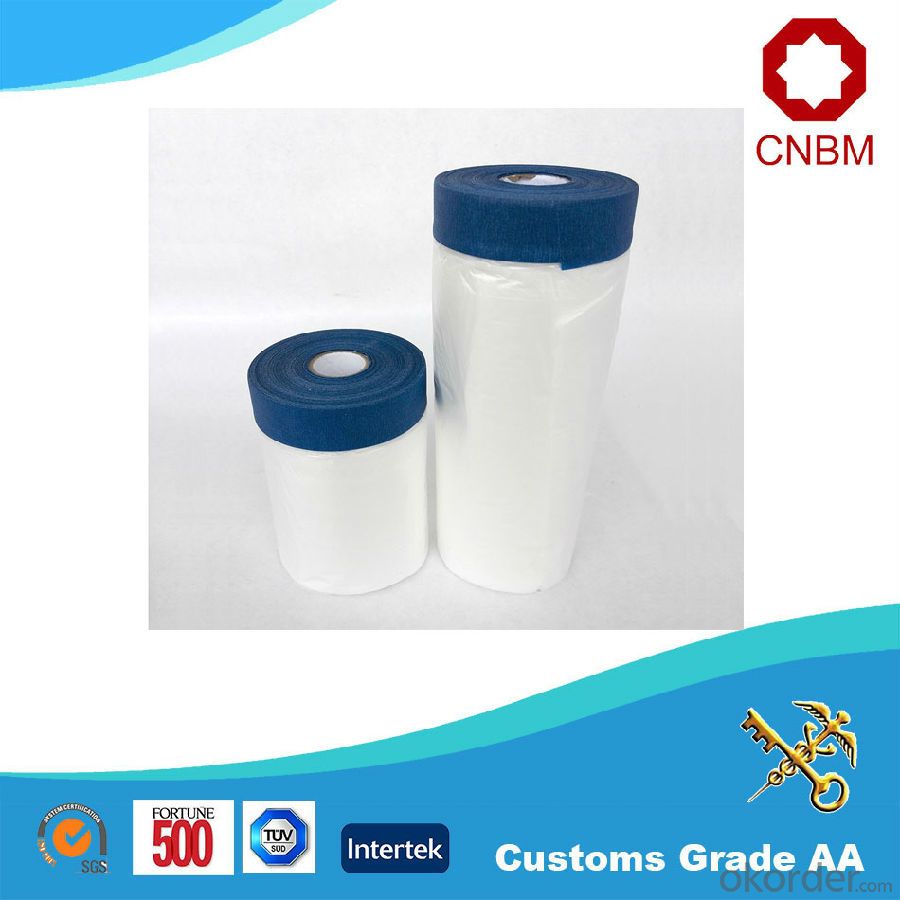

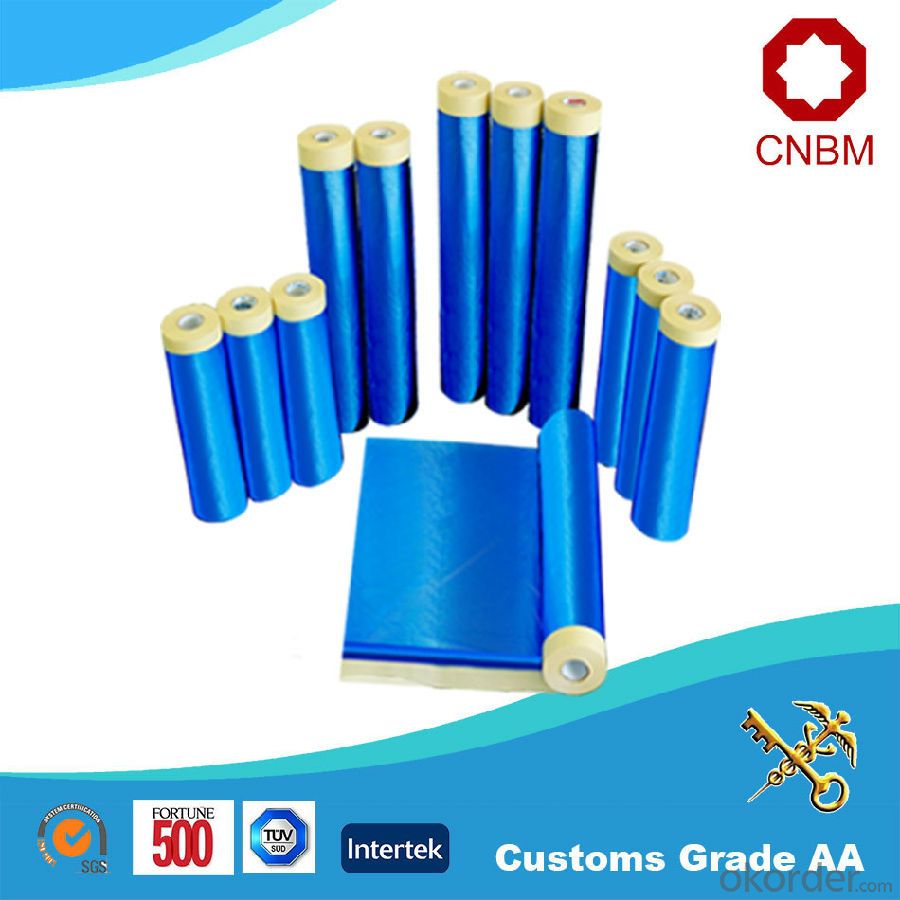

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q2.Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Yes, packaging tape can definitely be used for sealing household or kitchen items. It is a versatile adhesive tape that is commonly used for sealing cardboard boxes, but it can also be utilized for sealing various items in the household or kitchen. Whether you need to seal food containers, plastic bags, or even small appliances, packaging tape can provide a strong and secure seal. It is important to ensure that the surface is clean and dry before applying the tape to maximize its adhesive strength.

- Q: Does packaging tape come in different lengths?

- Indeed, packaging tape does come in a variety of lengths. Diverse lengths of packaging tape are accessible to cater to distinct packaging requirements. Standard lengths for packaging tape comprise 55 yards, 110 yards, and 1000 yards, although additional lengths might also be obtainable. The length of the packaging tape you opt for is contingent upon the size and quantity of packages you intend to seal. It is crucial to take into account the required length of packaging tape to guarantee an adequate supply for securely sealing your packages, without the risk of running out.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Packaging tape is not recommended for sealing chemical or hazardous material containers. This is because packaging tape typically does not have the necessary properties to effectively contain and prevent leakage of these substances. Chemical or hazardous materials often require specialized containers and sealing methods to ensure safety and compliance with regulations. These containers are designed to withstand the corrosive or reactive nature of the substances they hold, and their seals are engineered to provide a secure and leak-proof closure. Using packaging tape to seal chemical or hazardous material containers can pose risks such as leakage, contamination, and exposure to harmful substances. It may not provide a reliable barrier against leaks or spills, which could result in accidents, injuries, or environmental damage. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are designed for these purposes. This may include specialized caps, gaskets, or seals that are compatible with the particular substance being contained. Additionally, it is crucial to follow the guidelines and regulations provided by relevant authorities for the safe handling, storage, and transportation of these materials.

- Q: Does packaging tape come in different widths for different applications?

- Packaging tape indeed comes in a variety of widths to suit different purposes. You can find packaging tape in a range of widths, starting from as little as 0.75 inches and going up to 3 inches or even wider. The width you choose depends on the specific task at hand and the size of the package you are sealing. When dealing with lighter packages or sealing small boxes or envelopes, it is common to opt for narrower widths. Conversely, wider tape is frequently used when dealing with heavy-duty or larger boxes that require added strength and security. With the availability of different widths, users can easily select the most suitable tape size based on their unique packaging requirements.

- Q: The production of transparent tape material is what to do

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: What is the difference between acrylic and hot melt packaging tape?

- Sealing boxes and packages commonly involve the use of acrylic and hot melt packaging tapes, but they differ significantly in their adhesive properties and performance. Acrylic packaging tape boasts clarity and transparency, making it perfect for situations where package appearance matters. It also resists yellowing and aging, ensuring that it remains clear and does not become brittle over time. With a strong initial tack, acrylic tape adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as its adhesive strength can diminish when exposed to high heat or cold conditions. In contrast, hot melt packaging tape consists of a synthetic rubber adhesive that is applied as a hot liquid. This tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It excels in temperature resistance, maintaining its adhesive properties even in extreme conditions. Additionally, hot melt tape is known for its quick and effortless release, making it convenient for high-volume packaging operations. In conclusion, acrylic and hot melt packaging tapes are both effective for sealing boxes, but they have distinct advantages and disadvantages. Acrylic tape is ideal for situations prioritizing clarity, aging resistance, and initial tack. On the other hand, hot melt tape excels in adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q: How does packaging tape differ from masking tape?

- Packaging tape differs from masking tape primarily in terms of their intended uses and adhesive properties. Packaging tape is specifically designed for sealing boxes and packages, providing a strong and durable bond that can withstand shipping and handling. It is usually made of a strong material like polypropylene and has a strong adhesive that sticks well to various surfaces, including cardboard and plastic. On the other hand, masking tape is designed for temporary applications like painting and crafting. It has a less aggressive adhesive that allows for easy removal without leaving residue or damaging surfaces. Masking tape is typically made of paper and is not as strong as packaging tape, making it unsuitable for heavy-duty tasks like sealing boxes for shipping.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: Are there any safety precautions to consider when using packaging tape?

- There are various safety measures to take into account when utilizing packaging tape. To begin with, it is vital to work in a well-ventilated area to avoid inhaling excessive adhesive fumes, which can be harmful. Furthermore, it is crucial to handle the tape dispenser cautiously to prevent any injuries. Ensure that your hand placement is correct and avoid placing your fingers too close to the cutting blade to avoid unintended cuts. Moreover, it is advisable to wear appropriate protective gear, such as gloves, when using packaging tape to shield your hands from potential adhesive residue or cuts. Finally, it is essential to store the tape in a safe and secure location, out of reach of children or pets, to prevent accidental ingestion or misuse. By adhering to these safety measures, you can guarantee a secure and effective utilization of packaging tape.

- Q: Does packaging tape come in different dispenser designs for ergonomic use?

- Yes, packaging tape does come in different dispenser designs that are specifically created for ergonomic use. These designs focus on providing a comfortable grip and reducing strain on the hand and wrist during tape application.

Send your message to us

Discount Packaging Tape for Plastic Film Masking in Auto Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords