DIN Flanged Ball Valve Stainless Steel & Carbon Steel PN16

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard or Nonstandard: | Standard | Structure: | Control | Pressure: | Medium Pressure |

| Power: | Solenoid | Material: | Plastic | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | 1/8" | Place of Origin: | Zhejiang China (Mainland) |

| Model Number: | DSF-1/8-FF-A | Brand Name: | masoneilan control valves | Color: | Customised Pantone Color |

| Holding Power VA: | 5.5VA | Certification available: | Yes | Sample Time: | 3-5days if you want to customize your logo |

| MOQ: | 200pcs | Logo: | Any printing we can make for you just send the design to us! | OEM: | Professional OEM manufactory |

| Holding current: | 0.18A/24VAC | Voltage: | 12/24VAC, 12/24VDC, 6-40VDC,110VAC and 220VAC with solenoid |

Packaging & Delivery

| Packaging Detail: | 20PCS/CTN |

| Delivery Detail: | 35 days (according to the order quantity) |

Specifications

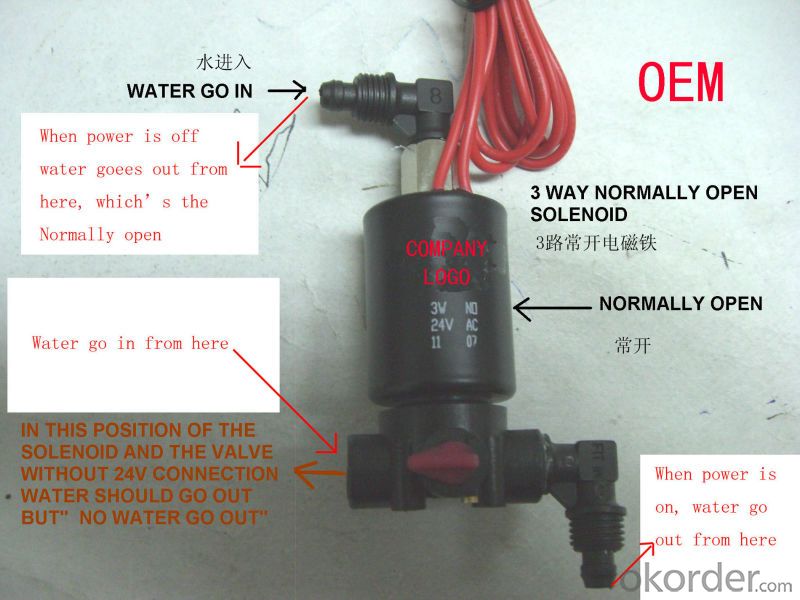

masoneilan control valves DSF-1/8-FF-A in 1/8" inch size

Control by the irrgation solenoid to on-off the valve

OE

masoneilan control valves : DSF-1/8-FF-A

Economical irrigation valve designed primarily for the residential and light commercial use, and it features solid construction, convenient operation and reliable performance. This solenoid valve series have 3 options: without Manual, or with Manual, or with flow control, for each type, they can be matched our irrigation solenoids (S391 series plastic encapsulated & S392 series metal shell) produced by our company at the voltage of 6-40VDC latch, 12/24VAC, 12/24VDC, 110VAC etc.

PS. The solenoids assembled with the valves are optional, for the specific solenoids specifications refer to the irrigation solenoids section of this catalogue. Option of 12/24VAC, 12/24VDC.6-40VDC Latch, 110VAC ,220VAC etc

The superiority to purchase the whole valve with solenoid in our company:

1)Regarding to the price, overall buy must buy cheaper than separate.And also the cost of shipment will be cheaper if you have to let us send the solenodis to the other valves factory to assemble.

2)Regarding to the delivery time. If we produce the overall we can send them together and will be faster than the sending them separate by different factory with different delivery time and production scheduling..

3)Regarding to the quality assurance, it is most important because we can test them overall and it will be easier to find the problem and repair them fast..If have the problem we can solve them much easier and more convenience..Or as you know if you have the different solenoids and valves supplier, if you have problem found in your company it will be much more inconvenience and also will cost a lot of time and money to change from two different suppliers..That will be a big problem..Anyway some problem if we produce the overall we can found them more easier such like the wrong dimensions,wrong performance..Because some problem may not be tested by separate testing.

4)For us more experience both in producing the soelnoids and valves will be a big quality assurance for all the customers and also easier to find the problem and research and development the new products..

Features:

1) Option of without manual, with manual or flow control

2) Valve body made of Aging-proof Corrosion-Resistant Reinforced Nylon for the long life duration.

3) Rugged synthetic rubber diaphragm provide the lead-proof seal

4) Special valve configuration with the self-cleaning function, debris-tolerant.

5) Self-aligning bonnet permits fast and easy maintenance

6) High-flow, low-friction-loss design.

Specifications:

Calibre inch | Max Pressure | Flow Rate | Rated Voltage | Initial Power | Holding Power |

1/8 | 0.069 ~ 1.05 | 12 ~ 120 | 24VAC / 50Hz | 10.5VA | 5.5VA |

Pressure Loss

Flow Control | Pressure Loss |

12 | 32 |

20 | 34 |

40 | 31 |

60 | 23 |

80 | 25 |

100 | 38 |

120 | 55 |

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: How about the valve?

- Now, there is an office in Beijing, valve enterprises in the valve, a lot of online ah, you click to see if you want information

- Q: What valve should be used to test the water valve?

- 1, ball valve.2, the water test valve can be ball valve, gate valve, stop valve, installed in the fire sprinkler system at each level of the end of the pipe.

- Q: Measure the temperature with a thermocouple, and then how to make the valve open when the temperature reaches a certain value. When the temperature is lowered, will the valve be closed?Or tell my brother what is the knowledge, I can see it myself. Good. How much extra?!

- Switching type (one on and off)Block digital display with the upper and lower limit control valve opening and closing is goodProbably more than 100Regulating type (to keep temperature at a constant value)With PID valve position regulator can be very good controlAbout 300 more

- Q: What does the 4 point valve mean?

- Commonly used valves, pipes in the 4 points, 6 points, an inch, is the earliest use of the length of the British unit, metric units are 15, 20, 25 mm, and now people are also used to call 4 points, 6 points, an inch.1 inches =25.4 mm1 feet =12 inches1 inches =8 cents

- Q: What's the name of the valve?

- This is not a valve, it is a pipe bender.

- Q: Which valve can play a good regulatory role?

- A wide range of valves, the function is different, although like conventional butterfly valve, ball valve can play a regulatory role, but their role is not linear, so if you need to adjust the precision of the valve, it is best to select the control valve.

- Q: What's the sewage treatment valve with?

- Sewage treatment system valve requirements are not high, the use of butterfly valve is one of the most cost-effective. Butterfly valve manufacturers are many, the price is also different, as long as the right can.

- Q: Which valves are installed in a directional manner?

- Regulating valve, stop valve, eccentric butterfly valve, check valve, one-way valve, solenoid valve, pressure reducing valve, drain valve and drain valve. Needle core valve, V ball valve, part of the ball valve, there is flow.Few. Such as floating ball valve, the central butterfly valve does not flow requirements. In general, if the regular manufacturers of valves, flow direction will indicate the flow of medium, to get the valve can see.

- Q: Name: valve actuatorFunction: control valve switch by controlling air flow sizeIntended classification commodity code: 8412310090 (other linear acting pneumatic power unit, pressure cylinder)Shanghai Pudong Airport customs change classification: 84123900 (other pneumatic power unit)Commodity code information given by China Customs official network: 8412310090 (actuator, valve parts, valve actuation, pneumatic)Our goods encoding 8412310090 is classified to the Shanghai Pudong Airport customs dismissed, there are no friends of this commodity encoding on the official website of the detailed specifications defined, I Secretary in accordance with the valve function into 8412310090 encoding. Thank you

- Various types of valves, with the continuous improvement of various types of equipment, process, the types of valves are still increasing. But generally speaking, they can be divided into two major groups.(1) automatic valve. A valve that moves by itself depending on the capacity of a medium (liquid, air, steam, etc.). Such as safety valve, pressure reducing valve, check valve, steam trap, air trap, emergency shut-off valve and so on. (2) drive valve. A valve operated by hand, power, hydraulic, or pneumatic. Such as gate valve, globe valve, throttle valve, regulating valve, butterfly valve, ball valve, plug valve and so on.

Send your message to us

DIN Flanged Ball Valve Stainless Steel & Carbon Steel PN16

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 1000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords