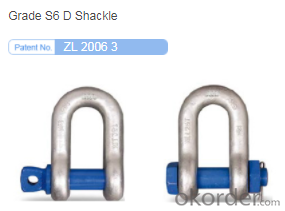

D-Shackle,It is made of high quality alloy steel by die forging.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forging Rigging

SHACKLES

The forging rigging factory 。 is the largest production base for forging rigging in Asia with advanced forging, heat treatment,surface coating and nondestructive testing equipment and the most advanced production technology.

Main forging equipment :5T size free forging hydraulic hammer,4000t、2500t、1000t size friction press machine and 750kg ~ 1000kg size air forging hammer etc. We also researched and developed 400t、1000t、1500t、2000t size bending machine. The annual producing

capacity is 20000t.

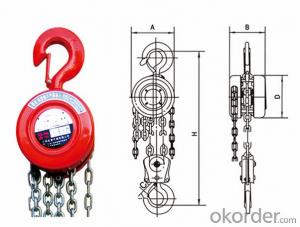

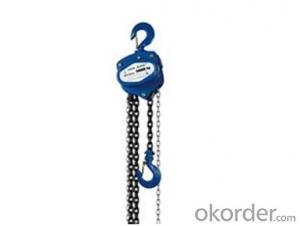

The shackles (both body and pin) we produce are made of high quality alloy steel through advanced production line and intermediate frequency furnace heat treatment. It is characterized by high-intensity, good toughness, small volume, light weight, beautiful appearance and good durability.

Product category: Flat shackle, Large WLL shackle with circular cross-section, Bow shackle, D shackle etc.

Production range: 0.5t-2000t

It is made of high quality alloy steel by die forging.

Each shackle will be marked with WLL permanently, WLL from 0.5t ~150t.

The Maximum testing load is twice of the working load ,while WLL is less than 85t(including),the minimum breaking load is 6 times of the WLL ,while WLL is more than 85t ,the minimum breaking load is 4 times of WLL .

Our products all correspond with the stipulated technical requirement and test approach in standard ISO2415-2004.

- Q: What is the influence of lifting angle on rigging?

- Slings are usually steel wire ropes or chain slings. Wire ropes have manganese phosphating coating, steel wire rope, galvanized steel wire rope, manganese phosphating coating, steel wire rope is new technology product, and fatigue life is three times of smooth steel wire rope.

- Q: Is rope sling good business and high profit?

- 1. phosphating coating steel wire rope, steel wire by manganese or zinc manganese phosphating, corrosion resistance and wear resistance steel rust resistance comprehensive jump, life is the same structure of plain steel wire rope 3 times (note the use of zinc phosphating and drawing rope with distinction, although Tianjin bonderizing Jiangsu have been a number of production enterprises, there is still a shortage of supply and demand)2. galvanized steel wire, hot-dip galvanized and galvanized3. stainless steel wire rope, 304 or 316 stainless steel4. coated steel wire rope, wire rope on the basis of the outer coating of polyethylene or polypropylene5. smooth steel wire rope, will be phosphating coating steel wire rope completely eliminated.

- Q: What is the line on the train for?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q: What are the precautions for rigging in hoisting works?

- When lifting heavy objects, heavy is prohibited to stand.

- Q: What are the installation steps for crane beams?

- Crane operation is relatively dangerous, the installation of crane beam should be standardized to ensure the safety of crane operation. How many points should I pay attention to when installing the crane?:(1) the actual elevation of the corbel should be measured before the installation of the steel crane beam, so that the construction error of the elevation can be adjusted when the crane beam is installed, so as to prevent the error accumulation.The installation sequence of crane beam is as follows: installing crane beam, installing auxiliary truss and installing brake beam.(2) crane shall be used by slings, lashing or reliable clamps. The binding point shall be determined according to the weight and length of the crane beam. Generally, the angle of the sling shall be greater than 45 degrees at the ends of the center of gravity of the crane beam.(3) should be placed after the crane beam, the connecting plate is connected with the fixed edge plate and column crane girder structure, to prevent the crane hook loose after crane girder longitudinal and lateral movement of dumping.(4) crane beam correction should be performed in all bolts after installation, to prevent the installation of bolts when the crane beam shift change; prohibited welding in the crane girder under the flange and web on suspension and fixture.(5) adjust the elevation of the crane beam, correct the center line and span after titanium.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- The main weight of a bridge is not the car or train on it, but the road itself, that is, the road we see. Now let's analyze this:We analyze it with a pylon. The two sides of the pylon are symmetrical stay cables which connect the main beam of the pylon through the stay cables. Now suppose that only two towers on both sides of the cable, symmetrical each one of the two cables subjected to beam gravity, two symmetrical of the cable along the direction of the force, according to the stress analysis, the stress can be decomposed into a horizontal and vertical force to a downward force a vertical force; and the same on the right side of the force can be decomposed into the right level of a downward force; the two force is symmetrical, so the two level of the left and right horizontal force cancel each other out,

- Q: How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q: Which sling manufacturer is more reliable?

- Rigging is made of wire rope, plug or aluminium alloy head, and the key to the service life of the rigging is the quality of the wire rope.

- Q: Types of slings for slings

- Metal slings are mainly wire ropes, slings, chains, slings and so on.

Send your message to us

D-Shackle,It is made of high quality alloy steel by die forging.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords