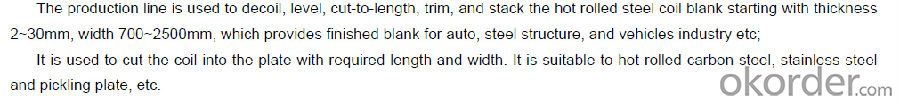

Cut-to-length Line for Hot Rolled Steel(Medium and Thick Plate)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: How to set the parameters for the processing of tungsten steel

- according to his given parameters of processing, and then summed up their usual processing of parts and the use of the electrode characteristics can be adjusted slightly to achieve the most good!

- Q: The characteristics of EDM wire cutting

- (4) can ignore the electrode wire loss (high-speed wire cutting using low loss pulse power; slow walking wire cutting using one-way continuous wire, in the processing area always keep the new wire wire processing), high precision (5)

- Q: Why does EDM work?

- Then discharge into the offftime period, discharge short stop, the electrode and the workpiece to restore the insulation state. X0d

- Q: EDM wire cutting can be normal operation, must meet the following conditions:

- 2, EDM WEDM machine processing, must have a certain insulating properties of the liquid medium, such as kerosene, saponification oil, deionized water, etc., require high insulation is to help produce pulsed spark discharge, liquid media

- Q: What are the advantages of wire cutting?

- 2, the direct use of electric power for pulse discharge processing, tool electrodes and the workpiece is not direct contact, no mechanical processing of the macro cutting force, suitable for processing low-rigidity parts and small parts.

- Q: EDM processing principle?

- EDM, also known as EDM EDM, is a use of electricity, heat energy processing methods

- Q: EDM machine hit a carbon, how to do?

- EDM machine in the discharge process, when the gap between the electrode and the workpiece to a certain distance, the application of the electrode and the workpiece 0ntime will medium (spark oil) breakdown, the formation of discharge channels, also produced a spark began to discharge

- Q: What is the wire cutting EDM machine?

- Also known as EDM machine, can be divided into forming electric discharge machine (EDM) and wire cutting EDM (EDM) two.

- Q: CNC wire cutting machine in the processing process, suddenly no discharge, what is the reason

- By the discharge processing erosion conditions constraints, to a certain extent, processing is very unstable, until there is no current discharge short circuit occurs.

- Q: What is the metamorphic element?

- The results show that the content of molybdenum content in the metamorphic layer is increased by the use of the molybdenum wire electrode in the molybdenum wire electrode. The content of the molybdenum element in the metamorphic layer is increased by the use of the copper wire electrode.

Send your message to us

Cut-to-length Line for Hot Rolled Steel(Medium and Thick Plate)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords