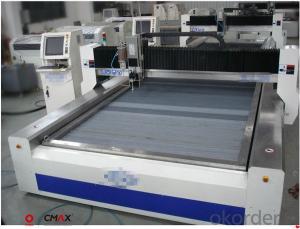

CNC Wire Cut EDM Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Packaging Detail: | International Standard |

| Delivery Detail: | Upon order details |

Specifications

1.CNC or Not:CNC

2.Dimensions:2300*1675*2220 mm

3.Total Weight:2500 KG

4.Condition:New

5.Place of Origin:China

Features:1.Prevention of overlapping or coating of wire material, and straightening of nylon wire;

2.Processing of nylon wire or zinc galvanized wire into jaw shaped and transmission it to the second station;

3.Counter for statistic of the whole production process;

4.Exchange of some spares without space change, to make change of diameter of double wire more convenient;

5.Double wire of 1/4-1 sharing one binding machine for automatic binding.

- Q: Machining (lathe, milling machine, grinder, wire cutting, discharge, general CNC, precision machining center) How much of the tool is consumed per month

- Different machine tools, different types of workpieces, different types of tools, different processing requirements, different processes, different batches of production, tool manufacturers different brands, different purchase channels, tool costs and consumption is very different.

- Q: How to effectively remove the whitening layer after discharge processing

- EDM mold parts of the main processing means of its physical nature of the decision to use the means of processing mold surface surface of the surface of the metamorphic layer of the surface layer of metamorphic layer, metamorphic layer mold quality of life impact of the analysis and policy

- Q: With the increase in wire speed, in a certain range, the processing speed will increase.

- At the same time, the improvement of the wire speed is beneficial to the discharge of the workpiece with the larger thickness of the working fluid, which is beneficial to the removal of the electric corrosion product and the stability of the electric discharge processing.

- Q: What is the specific processing of wire cutting?

- 3, regardless of the hardness of the workpiece, as long as the conductive or semi-conductive materials can be processed.

- Q: EDM machine how much money one

- Performance, and cost-effective and machine quality and after-sales service to buy the most suitable for your sparks machine manufacturers.

- Q: What is the speed of EDM processing?

- Mold in the EDM machine will generally use coarse, medium and fine processing of the file.

- Q: What is the discharge gap of the NC WEDM

- Cut you can first use 86 (I use the 86) and then in the FM 60 - 65 with the frequency (of course, the material to be as thick), so you can know the speed of the gap changes OK

- Q: EDM processing principle?

- by the discharge of local, instantaneous The high temperature of the metal is removed

- Q: EDM carbon slag and slagging

- Only actively create a good exclusion of the conditions, symptomatic to take some way to actively deal with.

- Q: Line cutting secondary cutting step polishing what is behind

- 2, stepper motor is the electrical pulse signal into angular displacement or line displacement of the open-loop control element stepper motor parts.

1. Manufacturer Overview

| Location | Jiangsu, China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America South America Southeast Asia Mid East Eastern Asia South Asia Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | shanghai,ningbo,yangzhou |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

CNC Wire Cut EDM Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 50 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches