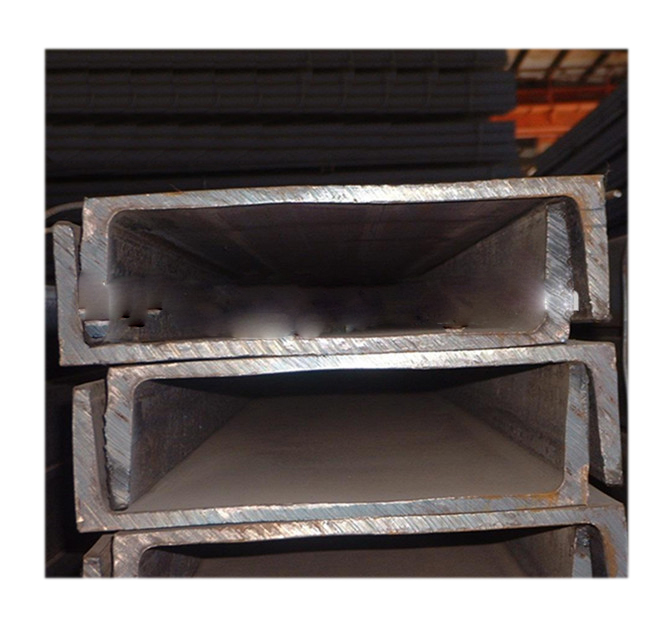

Custom Steel Channel (91mm X 8mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Custom Steel Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Custom Steel Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 9.0 – 14.5mm

Length: As per customer request

Max Dimensions: 90*37*4.5mm – 400*104*14.5mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

Light Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 6.4 – 8.0mm

Length: As per customer request

Max Dimensions: 50*32*4.4mm – 400*115*8.0mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are steel channels?

- Steel channels are structural components made from steel that are shaped like a "C" or a "U". They are commonly used in construction and engineering projects to provide support and stability. Steel channels are often used as beams or columns to carry heavy loads and distribute weight evenly. They can also be used as brackets or supports for various applications. These channels are durable, strong, and resistant to deformation, making them a popular choice in the construction industry. They are available in various sizes and thicknesses to accommodate different project requirements.

- Q: What are the common loadings considered in the design of steel channels?

- Steel channels are designed with consideration for several common loadings. These loadings consist of dead load, live load, wind load, and seismic load. 1. Dead load: The weight of the structure itself and any permanent fixtures or equipment is referred to as dead load. For steel channels, this encompasses the weight of the channel itself and any attached components. Dead load remains constant and is typically calculated based on the construction materials' weight. 2. Live load: Temporary weight or load that can vary in magnitude is known as live load. This includes moving or variable loads that steel channels may encounter, such as people, vehicles, or equipment. Live loads are usually defined by building codes or industry standards and can differ based on the specific application. 3. Wind load: Wind load relates to the forces exerted on steel channels by wind. The magnitude of wind load depends on factors like the structure's height, the channels' shape and orientation, and the local wind speed. Considering wind load in steel channel design is crucial for ensuring structural stability and safety. 4. Seismic load: Seismic load denotes the forces generated by earthquakes or other seismic events. These forces can induce significant stress and deformation in steel channels. Designing steel channels should account for the seismic risk of the location and the expected ground motion to ensure the channels can withstand these forces and maintain structural integrity. In summary, the design of steel channels takes into account these common loadings to guarantee their ability to safely support the intended loads and meet the necessary structural performance requirements. By properly considering and analyzing these loadings, engineers can design channels that are structurally sound and can endure the forces they encounter in real-world conditions.

- Q: What are the different steel channel profiles available?

- There are several different steel channel profiles available, each with its unique characteristics and applications. Some of the commonly used steel channel profiles include C-channel, U-channel, Z-channel, and Hat-channel. C-channel, also known as American Standard Channel (ASC), is a versatile profile that is widely used in construction and structural applications. It has a straight web and flanges of equal length, forming a C-shaped cross-section. C-channels are often used for beams, columns, and purlins in building frames. They can also be used as a support for metal decking or as a base for overhead doors. U-channel, also known as a U-beam or American Standard Channel (ASC), has a U-shaped cross-section with flanges that are shorter than the web. U-channels are commonly used for applications requiring additional strength and stability, such as bracing, framework, and support structures. They are also used in the automotive industry for truck beds, trailers, and vehicle frames. Z-channel, also known as Zee or Zed, has a Z-shaped cross-section with two flanges and a web connecting them. Z-channels are often used in construction for applications where two pieces need to be joined together, such as wall studs, roof framing, and floor joists. They can also be used as a support for wall panels or cladding systems. Hat-channel, also known as furring channel, is a thin-gauge steel profile with a wide, flat top and two short, parallel legs. Hat-channels are commonly used as a support for drywall or other types of cladding materials in ceiling and wall applications. They provide a secure and stable base for attaching panels and can help improve soundproofing and insulation in buildings. These are just a few examples of the different steel channel profiles available in the market. The choice of profile depends on the specific application requirements, such as load-bearing capacity, structural stability, and compatibility with other building components. It is important to consult with a structural engineer or supplier to determine the most suitable steel channel profile for a particular project.

- Q: How do steel channels contribute to the overall sustainability of a construction project?

- There are several ways in which steel channels contribute to the overall sustainability of a construction project. To begin with, they are manufactured using recycled materials, which reduces the demand for new resources and lessens the environmental impact of mining and processing raw materials. This helps conserve natural resources and reduces the energy needed for production, making steel channels a more sustainable choice. In addition, steel channels have a lengthy lifespan and require minimal maintenance. They are highly durable and resistant to corrosion, enabling them to withstand harsh weather conditions and endure for many years without needing replacement or frequent repairs. This reduces the overall use of materials and generation of waste, making the construction project more sustainable in the long term. Moreover, steel channels are lightweight and easy to transport. This decreases energy consumption and greenhouse gas emissions related to transportation, as less fuel is needed to move them from the manufacturing facility to the construction site. Furthermore, their lightweight nature makes them easier to handle and install, reducing the necessity for heavy machinery and the associated energy consumption during the construction process. Lastly, steel channels can be easily recycled at the end of their lifespan. Unlike other construction materials, steel can be melted down and reused multiple times without losing its properties. This not only reduces the amount of waste sent to landfills but also diminishes the need for new steel production, further conserving natural resources and decreasing environmental impact. To conclude, steel channels contribute to the overall sustainability of a construction project through their use of recycled materials, long lifespan, lightweight and easy transportability, and recyclability at the end of their life. By incorporating steel channels into construction projects, we can reduce environmental impact, conserve natural resources, and promote a more sustainable built environment.

- Q: What is the weight per meter of different steel channel sizes?

- The weight per meter of different steel channel sizes can vary depending on the specific dimensions and thickness of the channels. However, as a general guideline, the weight per meter of steel channel sizes typically ranges from around 5.7 kilograms to 35 kilograms.

- Q: How do steel channels perform in acoustic applications?

- Due to their structural properties, steel channels are effective in acoustic applications. The rigidity and strength of steel make it an ideal material for sound barriers and vibration minimization. Constructing walls, partitions, or ceilings with steel channels can help isolate sound and prevent transmission. The dense nature of steel aids in absorbing and dampening sound waves, reducing intensity and preventing reverberation. This is particularly advantageous in noise-sensitive environments like recording studios, theaters, or conference rooms. Additionally, steel channels can be combined with soundproofing materials or insulation to improve their acoustic performance. Adding layers of foam, fiberglass, or acoustic panels to the steel channels further reduces sound transmission and enhances overall acoustic quality. Furthermore, steel channels provide stability and durability, ensuring the integrity of acoustic structures over time. They can withstand heavy loads and offer fire resistance, making them a reliable choice for acoustic applications. However, it is important to note that steel channels alone may not be sufficient for soundproofing in high-noise environments. The effectiveness of steel channels in acoustic applications also depends on factors like space design, construction quality, and the use of additional soundproofing techniques. In conclusion, steel channels play a valuable role in achieving sound control and acoustic performance in various applications. Their strength, rigidity, and sound-dampening abilities make them suitable for creating sound barriers and minimizing noise transmission.

- Q: Are steel channels suitable for gymnasium structures?

- Indeed, gymnasium structures find steel channels to be an appropriate choice. Owing to their resilience, potency, and adaptability, steel channels are widely employed in construction. Their ability to bear substantial weight and offer stability makes them an excellent fit for gymnasiums. Moreover, the ease with which steel channels can be fabricated and installed renders them a cost-efficient selection for gymnasium construction. Furthermore, the remarkable fire, corrosion, and pest resistance of steel channels guarantee the endurance of gymnasium structures. Ultimately, steel channels emerge as a trustworthy and pragmatic alternative for the construction of gymnasiums.

- Q: Can steel channels be used in DIY projects?

- Yes, steel channels can be used in DIY projects. Steel channels are versatile and can be utilized in a variety of applications such as constructing frames, supports, shelving, and even furniture. They are strong, durable, and can provide structural stability to your DIY projects. Additionally, steel channels are available in various sizes and shapes, allowing you to find the perfect fit for your specific project requirements. Whether you are working on a small-scale DIY project or a larger construction undertaking, steel channels can be a valuable addition to your arsenal of materials.

- Q: Can steel channels be used for rooftop installations?

- Yes, steel channels can be used for rooftop installations. Steel channels are often used in construction and are known for their strength and durability, making them suitable for supporting various structures, including rooftop installations.

- Q: What are the typical lengths of steel channels?

- The typical lengths of steel channels vary depending on the manufacturer and intended use. However, they are commonly available in standard lengths ranging from 20 feet (6.1 meters) to 40 feet (12.2 meters). These standard lengths are often used in construction projects and are suitable for various applications such as structural support, framing, and bracing. Additionally, manufacturers may offer custom cutting services to provide steel channels in specific lengths to meet the unique requirements of a particular project.

Send your message to us

Custom Steel Channel (91mm X 8mm)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords