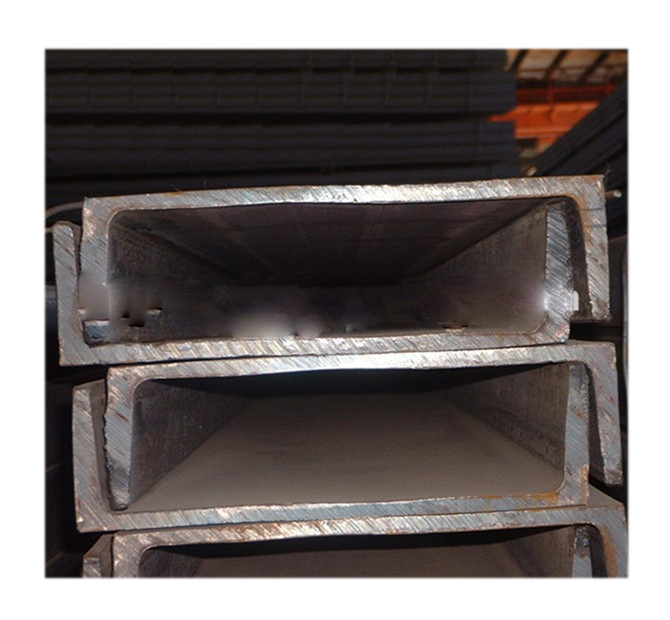

Custom Steel Channel (95mm X 8mm) Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Custom Steel Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Custom Steel Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 9.0 – 14.5mm

Length: As per customer request

Max Dimensions: 90*37*4.5mm – 400*104*14.5mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

Light Model

Grade: Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540, ASTM A36

Height: 90 – 400mm

Thickness: 6.4 – 8.0mm

Length: As per customer request

Max Dimensions: 50*32*4.4mm – 400*115*8.0mm

Surface: Painted, galvanized, as per customer request

Punch: Punched as per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels contribute to the overall safety of a structure?

- Steel channels contribute to the overall safety of a structure in several ways. Firstly, steel channels provide structural support and stability to the building. They are often used as load-bearing members in the construction industry, helping to distribute the weight of the structure evenly and efficiently. This ensures that the building can withstand various external forces such as wind, earthquakes, and heavy loads without collapsing. By providing a strong framework, steel channels enhance the overall safety and structural integrity of the building. Secondly, steel channels play a crucial role in fire safety. Steel is a non-combustible material, and when used as channels, it can help prevent the spread of fire within a structure. In the event of a fire, steel channels act as fire barriers, restricting the movement of flames and heat to specific areas. This containment helps to limit the damage caused by fire and provides occupants with more time to evacuate safely. Additionally, steel channels are resistant to corrosion and deterioration, making them highly durable and reliable. Unlike other materials, steel does not rot, warp, or degrade over time. This longevity ensures that the structure remains stable and secure in the long run, reducing the risk of accidents and structural failures. Furthermore, steel channels are often used in the construction of seismic-resistant structures. With their high strength and flexibility, steel channels can absorb and dissipate seismic energy during an earthquake. This ability to withstand seismic forces helps to minimize structural damage and ensures the safety of the occupants within the building. In conclusion, steel channels contribute significantly to the overall safety of a structure by providing structural support, fire resistance, durability, and seismic resistance. Their use in construction enhances the stability, strength, and integrity of the building, ensuring the safety and well-being of its occupants.

- Q: Can steel channels be used for mezzanine guardrails?

- Yes, steel channels can be used for mezzanine guardrails. Steel channels are often used for their strength and durability, making them suitable for providing a secure barrier and ensuring the safety of individuals on mezzanine floors.

- Q: Can steel channels be used for solar panel support structures?

- Yes, steel channels can be used for solar panel support structures. Steel channels provide strength, stability, and durability, making them suitable for supporting the weight of solar panels. Additionally, steel channels offer flexibility in design and can be customized to meet specific project requirements.

- Q: Can steel channels be used in earthquake-resistant buildings?

- Yes, steel channels can be used in earthquake-resistant buildings. Steel channels are commonly used in the construction industry due to their high strength and durability. In earthquake-resistant buildings, it is important to have a structural system that can withstand the lateral forces generated during an earthquake. Steel channels can effectively distribute and dissipate these forces, making them a suitable choice for earthquake-resistant construction. Steel channels provide several advantages in earthquake-resistant buildings. Firstly, they have excellent load-bearing capacity, which allows them to support heavy loads and resist the forces exerted during an earthquake. Secondly, they have a high modulus of elasticity, meaning they can deform under stress and then return to their original shape once the stress is removed. This flexibility helps prevent brittle failure and allows the structure to absorb and dissipate energy during an earthquake. Additionally, steel channels have a high ductility, which is crucial in seismic design. Ductility refers to the ability of a material to undergo large deformations without breaking. During an earthquake, steel channels can absorb and dissipate energy by undergoing plastic deformation, reducing the overall damage to the structure. Furthermore, steel channels can be easily fabricated and installed, making them a cost-effective option for earthquake-resistant construction. They are also readily available in the market in various sizes and shapes, allowing for flexibility in design. However, it is important to note that the use of steel channels alone is not sufficient to ensure complete earthquake resistance. The overall structural design, including the connections, bracing systems, and foundation, should be carefully considered and designed by a qualified structural engineer to meet the specific seismic requirements of the region. Building codes and regulations also play a crucial role in ensuring the safety and resilience of earthquake-resistant buildings.

- Q: What are the guidelines for steel channel installations in high-temperature environments?

- To ensure safety and optimal performance when installing steel channels in high-temperature environments, it is important to adhere to several guidelines. These guidelines are as follows: 1. Material Selection: Select a steel channel specifically designed for high-temperature applications. The chosen material should possess high-temperature resistance, such as stainless steel. This will prevent deformation or failure when exposed to extreme heat conditions. 2. Adequate Ventilation: Install steel channels in areas with proper ventilation to dissipate heat effectively. This will prevent the accumulation of excessive heat, which can potentially cause structural damage or compromise the installation's integrity. 3. Expansion Joints: Incorporate expansion joints into the steel channel system to accommodate thermal expansion and contraction. High temperatures cause materials to expand, and without expansion joints, the steel channels may experience stress and potential failure. 4. Proper Fixing and Support: Ensure that the steel channels are securely fixed and supported throughout the installation process. This involves the use of appropriate brackets, fasteners, and supports capable of withstanding high temperatures. 5. Insulation: Consider using insulation materials to protect the steel channels from extreme heat and minimize heat transfer. Insulation helps maintain the installation's structural integrity and prevents damage to surrounding components. 6. Regular Inspection and Maintenance: Regularly inspect the steel channel installation in high-temperature environments to detect any signs of damage, wear, or deformation. Promptly addressing any issues is crucial to prevent potential failures or accidents. 7. Compliance with Industry Standards: Adhere to relevant industry standards and regulations for steel channel installations in high-temperature environments. These standards provide specific guidelines and safety measures that must be followed to ensure a successful and safe installation. By following these guidelines, the installation of steel channels in high-temperature environments can be approached with confidence, resulting in a durable and reliable solution for various applications.

- Q: Are steel channels suitable for stadium construction?

- Yes, steel channels are suitable for stadium construction. Steel channels are commonly used in construction projects, including stadiums, due to their strength, durability, and versatility. They provide structural support and stability to the overall building, making them an ideal choice for large-scale projects like stadiums. Additionally, steel channels can be easily customized and fabricated to meet specific project requirements, allowing for flexibility in design and construction. They are also resistant to corrosion and can withstand heavy loads and extreme weather conditions, ensuring the long-term integrity and safety of the stadium. Therefore, steel channels are a reliable and efficient choice for stadium construction.

- Q: Can steel channels be galvanized or coated?

- Steel channels can indeed undergo galvanization or coating. Galvanization is a process wherein a layer of zinc is applied to the steel channel's surface to safeguard it against corrosion. This procedure involves dipping the steel channel into molten zinc or utilizing other techniques like electroplating or spraying to apply a zinc coating. By doing so, the zinc coating acts as a barrier between the steel and its surroundings, effectively preventing rusting. Alternatively, coating steel channels presents another option for corrosion protection. There exists a range of coating types, such as epoxy, polyurethane, or powder coatings, which can be applied to the steel channel's surface. These coatings establish a protective layer that shields the steel from moisture, chemicals, and other corrosive elements. Both galvanizing and coating steel channels serve to enhance their durability and extend their lifespan. The decision to employ galvanization or coating relies on various factors, including the intended application, environmental conditions in which the steel channel will be in use, and the desired aesthetic appearance.

- Q: What does channel C10 mean? What is the full name of C?

- C steel is different from the channel (such as "C10"), but he also called channel, C10 light is not enough, the leg length, wall thickness, edge are not stereotypes size, must be specifically marked.

- Q: Can steel channels be used in the automotive manufacturing industry?

- Yes, steel channels can be used in the automotive manufacturing industry. Steel channels are commonly used as structural components in the automotive industry due to their strength, durability, and versatility. They are used in various applications such as chassis frames, suspension systems, and body structures. Steel channels provide excellent load-bearing capabilities and can withstand the rigorous demands of the automotive industry. Additionally, their ability to be easily fabricated and welded makes them a preferred choice for automotive manufacturers.

- Q: How do steel channels contribute to sound insulation in buildings?

- There are several ways in which sound insulation in buildings can be enhanced by steel channels. Initially, one can utilize steel channels to establish a resilient channel system. This involves fastening the channels to the wall or ceiling studs and subsequently attaching the drywall to the channels rather than directly to the studs. This configuration creates a space between the drywall and the studs, effectively diminishing the transmission of sound vibrations from one side of the wall to the other. Moreover, steel channels can be employed to construct sound isolation walls or partitions. By incorporating multiple layers of drywall with steel channels interspersed, the channels aid in absorbing and dispersing sound energy. This technique significantly reduces the transfer of sound from one room to another, thereby fostering a more tranquil and comfortable environment. Additionally, steel channels can provide support for acoustical insulation materials. By filling the cavity between the steel channels with substances like mineral wool or fiberglass, the channels assist in absorbing sound and minimizing its transmission. This combination of steel channels and insulation materials fosters a more effective sound barrier, ultimately improving the overall sound insulation within the building. In essence, steel channels are vital components in bolstering sound insulation in buildings. They offer structural support for resilient channel systems, facilitate the construction of sound isolation walls, and provide a foundation for acoustical insulation materials. By employing steel channels in these various applications, the transmission of sound vibrations can be significantly reduced, resulting in a quieter and more serene indoor environment.

Send your message to us

Custom Steel Channel (95mm X 8mm) Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords