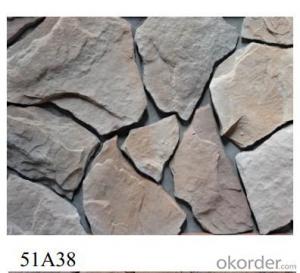

Culture stone 024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Material: Reef rock stone series

Size can be adjusted according to customers' requirements.

- Q: How to introduce plate-type furniture plate?

- Plate furniture can be said that the medium density fiberboard, solid wood particle board

- Q: Blockboard specifications Why is 2.44 * 1.22M, is the system board specifications on the board so much, or decoration industry in the size of the use of more convenient and so on? I want accurate information. Thank you

- Decoration industry in the size of the use of more convenient, is a molding

- Q: E0 and E1 grade plate how to distinguish?

- In fact, the grade of the plate refers to the finished sheet containing formaldehyde content of the level, which E0 level for the most advanced, the highest environmental index, with the least amount of formaldehyde, ≤ 0.5mg / L (belonging to the world's top standard); followed by E1, 1.5mg / L (in line with European standards); E2 level ≤ 5.0mg / L (in line with domestic standards). Although the higher the level of the amount of formaldehyde containing less, but also pay attention to the number of use, not because of environmental standards on the unlimited use, because the housing space is fixed, and the amount of superposition will make environmental protection exceeded. In addition, because the E0-class plate itself does not contain adhesives and moisture-proof agent, so its relative moisture resistance and toughness will be reduced, so not suitable for use in the kitchen, bathroom and other humid environment.

- Q: Villa special plate selection which brand plate?

- Landlord, decoration villa ah, it should not be short of money, you can decorate the point, and now are more emphasis on decoration with environmental protection, so the landlord can find some environmental decoration company to choose and reference. My house before the house decoration, do the decoration is relatively high-end, then choose the decoration of the company, they have been known for a herbal home improvement, my home is where the choice of natural Thai ecological floor, which is A more environmentally friendly floor, the performance is very good, the price is not too expensive, the landlord can see!

- Q: The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q: Jin Liyuan plate quality how

- My home is Jinliyuan plate, the quality is not bad, the measured quality has reached the national standard

- Q: What are the types of decorative plates?

- Decorative sheet types are blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC sheet, Aluminum plate, Aluminum plate, 3D board. Xiaobian today to simply introduce you to Glulam and PVC sheet two common life of the plate. Decorative materials are divided into two parts: part of the outdoor materials, part of the indoor materials. Indoor materials and then divided into stone, sheet, sheet, profile, wire five types. Decorative sheet is the general term for all plates, mainly: blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC board, Aluminum gusset plate, Aluminum plate,

- Q: What are the characteristics of spruce plate?

- Strong pine wood] to answer your questions about wood! ?? Spruce, also known as European white pine, its fine texture straight, material stability, not easy to deformation cracking, strong resistance, while easy to planing, planing the surface after the smooth, bright, can absorb paint and colorants, and Easy to glue. It itself has a soft color, fine texture and natural texture is very natural into the furniture design, showing a simple original beauty. Spruce has a variety of advantages and uses a wide range, has been hailed as "the Nordic green diamond." ????? Main use: furniture components, housing ceiling, decorative keel, floor, shutters, cabinets, wall panels, musical instruments, organ tubes, boxes, wooden barrels, joinery, cutting wood, sleepers, building structural materials, Bridges and other timber.

- Q: Where is the plate three-dimensional painting better?

- After the unremitting efforts of Fujian Zhonghuang company technical staff, on March 22, 2017, finally succeeded through Océ - Canon produced 360GT-UV flatbed printer to make the world's first, China's first largest format UV straight 3D solid plate Painting, the format to 2.0 meters * 2.5 meters, opened a large format 3D three-dimensional painting new stage. At present, the world's most advanced UV flatbed printer is our exclusive agent "Océ - Canon" produced 360 series UV flatbed printer, you can directly in the grating plate directly print three-dimensional picture, and now the device one-time maximum print format Can reach 2.5 meters * 3 meters, and the screen high-definition, full color, bright, strong adhesion, do not fade, high production, 3D is the new darling of the three

- Q: Is the picture below the S modeling faculty do very stiff want to achieve this and exactly the same effect Thank you!

- You can use the relatively soft wood to do, or use three-dimensional plastic to do, and then add a little sponge like plastic sofa.

Send your message to us

Culture stone 024

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords