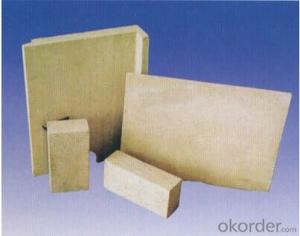

Cordierite-mullite Refractory Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Cordierite-mullite brick

1. low thermal expansion coefficient,

2. excellent stability of thermal shocking

| Alumina-Silica Refractory Series Products | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cordierite-mullite brick is of low thermal expansion coefficient, excellent stability of thermal shocking, it is used in assembly brick for hot blast stove. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Physical and chemical index :

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What are the different types of insulating fire bricks available?

- There are several different types of insulating fire bricks available, each with their own unique characteristics and applications. Some of the most common types include: 1. Lightweight Insulating Fire Bricks (IFBs): These bricks are made from lightweight materials, such as expanded clay, perlite, or vermiculite, which are blended with a binder to form a porous structure. They have excellent insulation properties and are commonly used in applications where high temperatures need to be maintained, such as in kilns or furnaces. 2. Mullite Insulating Fire Bricks: Mullite bricks are made from a combination of alumina and silica, resulting in a high-temperature resistant material. These bricks have excellent thermal shock resistance and are often used in applications where rapid heating and cooling cycles are involved, such as in glass manufacturing or incinerators. 3. Alumina Insulating Fire Bricks: As the name suggests, these bricks are made primarily from alumina, a high-temperature resistant material. They have excellent thermal conductivity and are often used in applications where high temperatures need to be maintained, such as in the iron and steel industry or in the production of ceramics. 4. Silica Insulating Fire Bricks: Silica bricks are made primarily from silica, a heat-resistant material. They have excellent thermal insulation properties and are often used in applications where high temperatures need to be maintained, such as in the construction of kilns or furnaces. 5. Calcium Silicate Insulating Fire Bricks: These bricks are made from a combination of calcium silicate and other insulating materials. They have excellent thermal insulation properties and are often used in applications where high temperatures need to be maintained, such as in the petrochemical industry or in power plants. Overall, the choice of insulating fire brick depends on the specific requirements of the application, including temperature resistance, thermal conductivity, and thermal shock resistance. It is important to select the appropriate type of insulating fire brick to ensure optimal performance and safety.

- Q: How do insulating fire bricks affect the overall insulation efficiency of a process?

- Insulating fire bricks significantly enhance the insulation efficiency of a process by providing a high level of thermal resistance. These bricks have low thermal conductivity and can withstand high temperatures, effectively minimizing heat transfer and reducing energy loss. This improved insulation helps maintain consistent and controlled temperatures, leading to increased energy efficiency and reduced fuel consumption in various industrial processes.

- Q: Can insulating fire bricks be used for sound insulation?

- Insulating fire bricks are primarily designed for thermal insulation in high-temperature applications, such as kilns and furnaces. While they do offer some level of sound absorption due to their porous structure, they are not specifically engineered for sound insulation purposes. Therefore, if your goal is to achieve effective soundproofing or noise reduction, it is recommended to use materials specifically designed for that purpose, such as acoustic panels, mineral wool, or other sound-absorbing materials.

- Q: What is the price of thermal insulation brick for exterior wall?

- But also depends on how your drawings are made, so as to quote a specific price. There is also the price of each place is not the same, so the quotation will be different.

- Q: How do insulating fire bricks affect the overall carbon footprint of a structure?

- Insulating fire bricks can significantly reduce the carbon footprint of a structure. These bricks have higher thermal insulation properties compared to traditional bricks, which means they can better retain heat and reduce the need for excessive heating or cooling. By improving energy efficiency and reducing the consumption of fossil fuels, insulating fire bricks help to lower the carbon emissions associated with the structure's operation. Additionally, their longer lifespan and recyclability contribute to further environmental benefits by reducing waste generation and the need for frequent replacements, ultimately minimizing the overall carbon footprint of the structure.

- Q: Do insulating fire bricks require any special fireproof coatings?

- Special fireproof coatings are not necessary for insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and offer exceptional insulation without the need for extra coatings. They are crafted from refractory materials with elevated heat resistance and minimal thermal conductivity. Insulating fire bricks find wide usage in kilns, furnaces, fireplaces, and similar high-temperature settings that demand insulation. Their inherent properties enable them to withstand intense heat without requiring any further coatings or treatments.

- Q: Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack.

- Q: What are the different sizes and shapes available for insulating fire bricks?

- Insulating fire bricks are offered in a variety of sizes and shapes to accommodate different applications and requirements. The size options for insulating fire bricks typically span from standard measurements like 9" x 4.5" x 2.5" (commonly referred to as "9-inch bricks") to smaller dimensions such as 9" x 4.5" x 1". These standard sizes are extensively utilized in the construction of fireplaces, kilns, furnaces, and other applications involving high temperatures. In addition to the standard sizes, manufacturers also provide insulating fire bricks in custom sizes, allowing for greater design and construction flexibility. The custom sizes may vary depending on the manufacturer, but they generally adhere to the same width and length measurements as the standard bricks. Regarding their shape, insulating fire bricks are typically rectangular or square. The rectangular shape is the most prevalent and versatile, enabling easy installation and arrangement in various structures. Although square-shaped bricks are also available, they may be less commonly utilized. It is important to note that insulating fire bricks can be further classified based on their density or insulation value. These bricks are typically categorized into three groups: low-density, medium-density, and high-density. Each category possesses distinct insulating properties, with low-density bricks offering the highest insulation value. In summary, the extensive range of sizes and shapes offered for insulating fire bricks allows for customization and adaptability to different construction projects, ensuring optimal insulation and heat retention in applications involving high temperatures.

- Q: Can insulating fire bricks be used in lime plants?

- Yes, insulating fire bricks can be used in lime plants. They are commonly used in high-temperature applications, such as lime kilns, to provide thermal insulation and reduce heat loss. Insulating fire bricks help maintain consistent and efficient heat distribution, which is essential for the lime production process.

- Q: Are insulating fire bricks porous?

- Indeed, porousness is inherent to insulating fire bricks. It is this attribute that enables them to exhibit low thermal conductivity. Comprised of ceramic materials, these bricks possess a considerable amount of minuscule air pockets or empty spaces. These cavities serve to capture and decelerate the flow of heat. Furthermore, this porosity renders the bricks lightweight and resilient against thermal shock. The efficacy of these insulating fire bricks in retaining heat and furnishing efficient insulation is unequivocally tied to their porous configuration.

Send your message to us

Cordierite-mullite Refractory Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords