Conical Or Parallel Twin-screw Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 60 days |

All kinds of extruders that our company designs especially for producing the PVC pipe and profile, our extruders

can promise a good plasticization, high capacity and advanced electric control, and the electrical cabinet can be chosen by customer according to their own demands

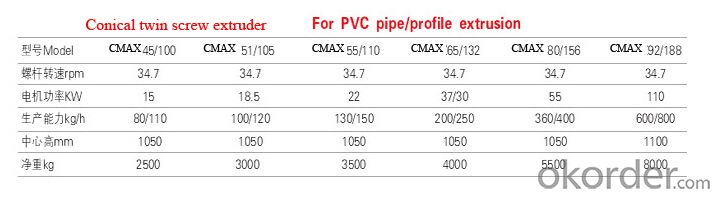

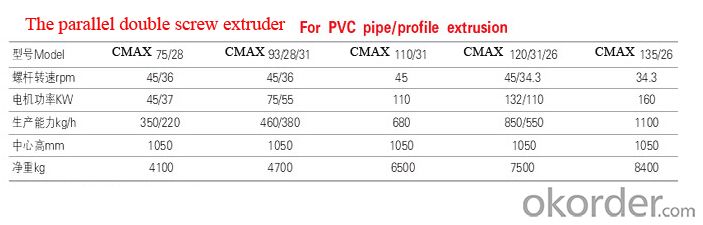

Technical parameters

All Key parts: screw&barrel, die, calibrator and downstream equipment are made by Jwell factory!

FAQ

1. What are CNBM coming from?

Jwell made the first Chinese screw and barrel in 1978 in brand. Nowaday, in this location BEIJING city, there are more than thousands of companies. After more than 35 years development, CNBM is the TOP 1 extrusion machine supplier in China

2. Why should I choose CNBM?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

- Q: Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What is the adjustment method of China's extrusion machine die?

- (3) line to die: suitable for small section of wire and cable adjustment. Pass the wire through the mold core, connect to the traction line, then run the glue and fine tune it. When the glue is running, adjust the screw and the traction speed, start the car, take the line sampling, and then stop to observe the thickness of the plastic layer of the sample is even, repeated several times until the tune until so, and then tighten the screws

- Q: Extrusion blow molding machine, storage or continuous type good?

- and material in the screw for a long time to use the storage type is also in order to meet the demand for raw materials productsIf you are doing small things, your hourly output will not consume the maximum hour.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- Operating procedures are based on the preparation of equipment instructions, you can increase some of the preparatory work before the boot, the middle is the operation of equipment instructions, and finally must have safe and civilized operation instructions!

Send your message to us

Conical Or Parallel Twin-screw Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords