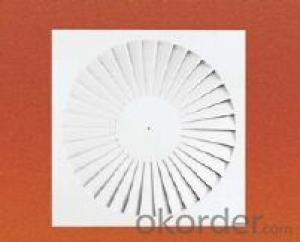

Cone Air Diffuer Stamped Steel Face Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Cone Air Diffuer Stamped Steel Face Construction Air Condition Vent Mold Exhaust Air Valve for Construction or building

Air condition vent mold Exhaust Air Valve Is Engineered polymer construction, Three-way deflection,Traditional styling,Integral multi-shutter damper with easy to use damper handle For heating or cooling applications

Specifications of Cone Air Diffuer Stamped Steel Face Construction Air Condition Vent Mold Exhaust Air Valve for Construction or building

Exhaust Air Valve

Made of Galvanized Steel

exhaust air valve

Size 80, 100, 125, 160, 200mm

Removable core, with collar

Exhaust Air Valve

Material: Galvanized Steel

Finish: White powder coated

Size: 80mm, 100mm, 125mm, 160mm, 200mm

Removable core, with collar

For ceiling air supplying

Easy installation, and good performance

Packaging Detail: Standard export packing ,Your requirment accept.

Delivery Detail: 3-5 weeks

Advantage of Air Condition Vent Mold Exhaust Air Valve for Construction or building:

1.Competitive price.

2.Continuance service and support.

3.Diversified rich experienced skilled workers.

4.Custom R&D program coordination.

5.Application expertise.

6.Quality,reliability and long product life.

7.Mature,perfect and excellence,but simple design.

Feature of Air Condition Vent Mold Exhaust Air Valve for Construction or building

Engineering capabilities include:

1.Parts design.

2.R&D products.

3.Prototype design and production assembly.

4.Reputable design software used for all design work.

5.Hot runner design.

6.Cold runner design.

7.Fast automatice remould design.

8.Mold design with a team of experienced specialists.

Process of our company :

1.Quote competitive price according customer detail requirement.

2.Sign agreement.

3.Customer T/T deposit to us to start to design mould.

4.Send mould drawing to customer for confirmation.

5.Mould design confirmed and start to make mould.

6.Make mould trial during tooling time (which we get agreement with customer)

7.Send mould trial sample to customer for inspection.or customer come to our factory to inspect mould personally.

8.Customer T/T balance to us after mould confirmed.

9.Deliver mould after get balance.

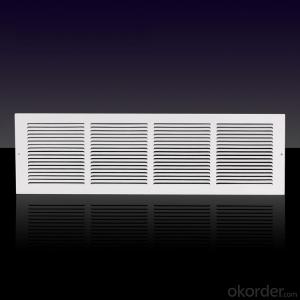

Application of Air Diffusing Grille for Construction or building :

It is mostly used on the sidewall outlet type air distribution. We always export to supermarket to USA ,CHILE ETC. For heating or cooling applications.

FAQ :

1.What is the air grille?

It is made of plastic (ABS PVC,PP PE)or steel metal ,aluminum steel by mould. It could be used for sidewall ,outletype air distribution, heating or cooling applications.

2.what kind of grille we have ?

We have ABS /PP/ PVC Plastic Air Diffusing Grille, aluminum swirl air diffusers, floor register, return air grille , wooden register ,plastic air grille, aluminum air grille, baseboard registers, celling side way registers, plastic air vent, blades dampers, etc .

3.what is the application of our grilles?

It could be used for sidewall ,outletype air distribution, heating or cooling applications.

4. what kinds of design we have ?

Please check our catalogue or website for reference. Or we could make design as your ideas . We have professional technical team . they could make what you imagine.

- Q: What is the function of the air conditioning condenser?

- A refrigerant that passes from a high-pressure, high temperature gaseous refrigerant (like water vapor, becomes water) and becomes a liquid coolant at high pressure

- Q: What are the parts of the outdoor unit?

- The outdoor unit comprises a compressor, a heat exchange copper pipe, an expansion valve, a four way valve, a liquid storage tank, an exhaust fan and an electric component

- Q: How to deal with the liquid hammer phenomenon of compressor

- The cause of liquid hammer is refrigerant or excessive lubrication, the liquid is too fast, the expansion valve (or valve) the regulation degree (opening) is too large, the heat load of evaporator (heat transfer) is not stable, large open type compressor suction valve open too fast (or unloading capacity too fast). System design and installation is unreasonable, abnormal shock may have caused the compressor

- Q: What's the difference between compressor and air compressor?

- Air compressor: the abbreviation of air compressor, its medium is air

- Q: What are the air compressors for?

- The food and pharmaceutical industries use compressed air to stir the slurry

- Q: What is the working principle of the BOG compressor?

- General BOG compressor uses oil-free lubrication reciprocating compressor, the working principle is the same as the ordinary reciprocating compressor. The difference is that the inlet of the BOG compressor is low temperature gas, so the first stage cylinder block, piston and so on must be able to withstand low temperature, and also to prevent freezing

- Q: What are the types of compressors?

- The liquid piston compressor is a rotary displacement compressor in which water or other liquid acts as a piston to compress the gas and then exhaust the gas

- Q: What are the parts of an automobile air conditioner?

- The evaporator absorbs heat from the gas through the evaporation of the liquid refrigerant; the condenser condenses through a gaseous refrigerant that releases heat from the refrigeration system into the air outside the car

- Q: What are the technical parameters of the compressor?

- The exhaust heat is the sum of the equivalent heat of the compressor's refrigerating capacity and part of the compressor's input power, which is discharged through the condenser in the system. This parameter is a very important performance index for the compressor in the heat pump system. It is also necessary to design the condenser of the refrigeration system.

- Q: What are the differences and characteristics of D M type V compressor?

- Both D and M compressors are mature compressor structures. If large displacement is required, the M model is recommended because the force of the crankshaft is more balanced, and the layout of the crankshaft is more reasonable, but the area is larger.

Send your message to us

Cone Air Diffuer Stamped Steel Face Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords