Solar Mounting Systems - Concrete Support System, Solar System Bracket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

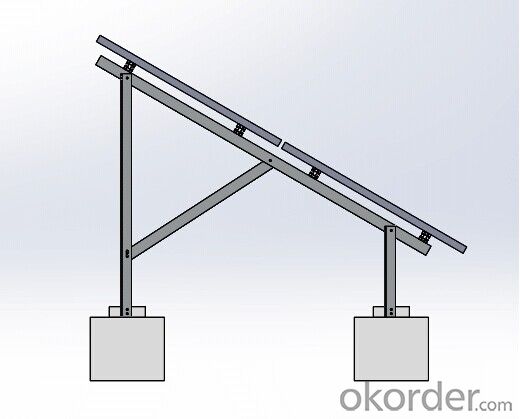

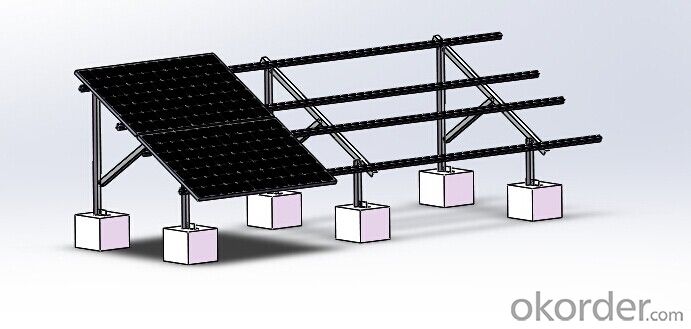

Concrete Support System, Solar System Bracket

Concrete support mounting structure for solar PV system. This system designed by local ground situation and it is a cost effective type.

Features:

1. Feature for solar mounting system with concrete embeddedbolt.structure customization,drill and welding free and fast installation.

2. appearanceand generous,without secondary anticorrosive processing.

3. ahead and rear of baseboard can be adjusted ,easy to be rectified in construction.

Specification:

| Installation site | Outdoor ground |

| Installation angle | customization |

| Wind resistance | 35m/s |

| Solar Panel Type | frame or frameless |

| Solar panel size | any size |

| Mount track | aluminum extrusion attachment |

| Mount materials | Q235B |

| Installation height | customization |

| Snow load | 1.4KN/m2 |

| Components arrangement | laterally or longitudinally |

| International Standards | comply with AS/NZS 1170 and other international standards |

| Quality Warranty | 20 years |

- Q: How does a solar mounting system protect against wind damage?

- A solar mounting system protects against wind damage by securely anchoring the solar panels to the roof or ground. It uses strong materials and a sturdy design to withstand high wind speeds, preventing the panels from being lifted or displaced. Additionally, some mounting systems incorporate features like tilt angles and aerodynamic designs to reduce wind resistance and enhance stability.

- Q: Can a solar mounting system be used with solar-powered remote monitoring systems?

- Yes, a solar mounting system can be used with solar-powered remote monitoring systems. The solar mounting system provides the structure and support for the solar panels, while the remote monitoring system allows for real-time tracking and analysis of the solar power generation. By combining these two systems, one can effectively monitor and optimize the performance of the solar panels in a remote location.

- Q: Can solar mounting systems be installed on rooftops with satellite dishes?

- Yes, solar mounting systems can typically be installed on rooftops with satellite dishes. However, it is important to ensure proper placement and coordination between the solar panels and satellite dish to avoid any potential shading issues.

- Q: Can a solar mounting system be used on agricultural buildings?

- Yes, a solar mounting system can be used on agricultural buildings. Solar panels can be installed on the roofs or sides of agricultural structures, such as barns or sheds, to generate clean energy and reduce electricity costs for farming operations.

- Q: Can a solar mounting system be used for both residential and commercial applications?

- Yes, a solar mounting system can be used for both residential and commercial applications.

- Q: What factors should be considered when choosing a solar mounting system?

- When choosing a solar mounting system, several factors need to be considered. Firstly, the type of roof or ground where the solar panels will be installed is crucial. The mounting system must be compatible with the specific roof type (such as flat or sloped) or ground conditions (such as soil or concrete). Secondly, the weight and size of the solar panels should match the load-bearing capacity of the mounting system to ensure safety and stability. Additionally, the location and climate should be taken into account, as certain mounting systems are better suited for high wind or snow regions. Lastly, the cost, ease of installation, and compatibility with other components in the solar system should also be considered to optimize efficiency and affordability.

- Q: Can a solar mounting system be used in areas with limited access to solar advocacy groups?

- Yes, a solar mounting system can be used in areas with limited access to solar advocacy groups. Solar mounting systems are engineering structures that securely hold solar panels in place, allowing them to efficiently capture sunlight and convert it into electricity. While solar advocacy groups can provide valuable support, guidance, and resources for individuals or communities interested in solar energy, the installation and use of solar mounting systems do not necessarily require the involvement of advocacy groups. Many solar mounting systems come with detailed installation instructions, and professional installers or contractors can also be hired to ensure proper setup. Additionally, there are online resources, tutorials, and forums available for individuals to learn about solar energy and installation techniques, making it possible for areas with limited access to solar advocacy groups to still benefit from solar mounting systems.

- Q: What is the maximum tilt angle for a solar mounting system?

- The maximum tilt angle for a solar mounting system typically depends on various factors such as the geographical location, climate conditions, and specific requirements of the solar installation. However, in general, the maximum tilt angle can range from 20 to 45 degrees.

- Q: Are there different mounting systems for residential and commercial solar installations?

- Yes, there are different mounting systems for residential and commercial solar installations. Residential solar installations typically use roof-mounted systems, such as flush mounts or tilted racks, to maximize space utilization on residential rooftops. On the other hand, commercial solar installations often use ground-mounted systems or larger-scale roof-mounted systems, which can accommodate a higher number of solar panels and are designed to withstand heavier loads.

- Q: Can a solar mounting system be used in areas with solar incentives for manufacturing facilities?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for manufacturing facilities. In fact, utilizing a solar mounting system can be highly beneficial in such areas as it allows manufacturing facilities to harness solar energy effectively, reduce their reliance on traditional grid power, and take advantage of the financial incentives provided by the government or local authorities for adopting renewable energy sources.

Send your message to us

Solar Mounting Systems - Concrete Support System, Solar System Bracket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords