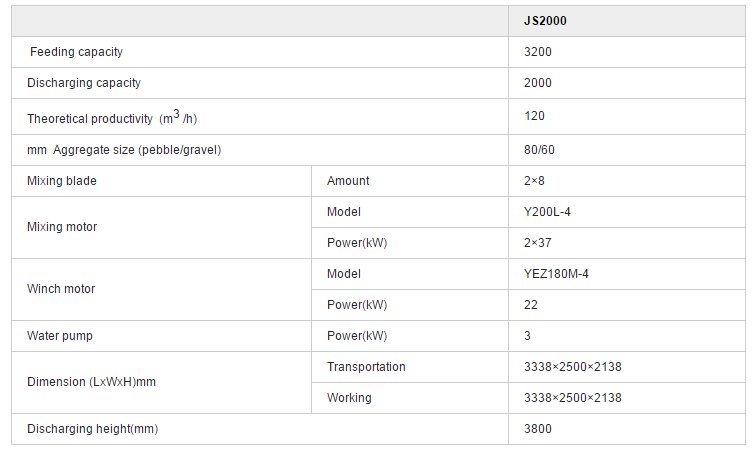

Concrete mixer JS2000 / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Technology Center of Yuanyou Heavy Industry is a certified Enterprise Technology Center of Shandong Province; it has a mass of senior R&D engineers, good R&D environment and R&D mechanism which inspirit strong R&D and innovation ability. The center mainly focuses on the technical research, the application of the new technologies and materials, and the development of new products in the fields of construction machinery, building machinery, road machinery, and dry mixed mortar equipment, etc.

The Technology Center is the product and R&D department of Shandong Yuanyou Heavy Industry Science & Technology Co., Ltd., which mainly undertakes the technology and product R&D and technology management. There are five R&D departments, respectively mixing machinery R&D department, dry mortar equipment R&D department, construction machinery R&D department, automation R&D department, and new material R&D department. Every year, there is technology innovation and technical transformation project selected as major project of Weifang city or Shandong province. The recently developed energy-saving and environment friendly air-conveying concrete mixing plant is selected as one of the major technical innovation projects of Shandong province, and it gains the certificate of New Product and New Technology of Shandong Province. The project of “Technical Transformation Project of Energy-Saving and Environment Friendly Air-Conveying Concrete Mixing Plants” with annual output of 200 is approved to be the Top 10 Major Energy-Saving Engineering Project in China and the New Central Government Budgeted Investment Plan Project by National Development and Reform Committee (NDRC). The success of the product lays a solid foundation for the product upgrade and structure optimization, and plays an active role in expanding market and promoting the development of the enterprise. The center always insists on combining the production with research, and successively sets up relationships with colleges and research institutes.

The product is widely used in key projects like various highways, railroads, high-speed railways, airports, ports, bridges, and hydropower stations, as well as commercial concrete mixing station, real estate, and municipal construction. With constantly increasing investment in technological innovation, the company has achieved great achievements and been recognized as “Provincial Enterprise Technology Center” in 2008. The company has 4 research department respectively specializing in mixing, transportation, conveying, and automation.

Yuanyou JS series concrete mixer is double horizontal spindle forced mixer. It can work alone, or be combined with Yuanyou PL series batching plant to work as simplified concrete mixing plant, or work as the main machine of the mixing plant. It can be utilized in large, medium-sized, and small precast concrete plant and projects like roads, bridges, water conservancy, ports, and industrial or civil constructions. It can be used to mix dry concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortars. It is a highly efficient machine with extensive applications.

Yuanyou concrete mixer features:

1. Large diameter drum prolongs the service life of the steel wire rope;

2. Wear-resistant alloy casting plate and blade can prolong the replacement interval of the wearing parts;

3. 100% full load test ensures reliable operation.

Batching machine also available.

- Q: What are the pros and cons of a concrete mixer?

- Are you talking about the production line at the blender station or is it the usual blender or that? These I understand

- Q: Concrete mixers need to be aware of which things

- The concrete mixer driver must be familiar with the performance and operation of the machine, and wear the protective equipment according to the regulation. Article 2: before work should check whether the transmission clutch and brake is flexible and reliable, climbing rope fights with and without broken wires, transmission components such as the mixer of the big gear, pulley guard is in good condition, whether the motor grounding is good, confirmed rear can work. Article 3: the driver is not allowed to leave the job in the operation of the machine, and when the blender is running, it is forbidden to reach into the mixing bowl with an axe, spade or any other object. Article 4: when the hopper arises, no one shall pass or stay in the hopper. If it is necessary to check and repair, the power should be cut off, and the bucket will be held in the back of the link. Article 5: when the feeding operation is strictly prohibited, the operator will put the head into the hopper and the rack to inspect the loading condition. Article 6: if you need to go into the mixing tube for cleaning, you should disconnect the power supply, remove the fuse, and put the lock on the switch box, or be guarded by a special person.

- Q: How many square concrete can be produced in an hour of concrete mixer

- One hour of theoretical productivity is 50, which is actually about 40. Because it takes time to get into the car and get out of the car, it's not a matter of machine production.

- Q: What is the difference between a concrete mixer and a mortar mixer

- Concrete is made by mixing several kinds of aggregates and water, cement and mixing. Because of containing coarse aggregate, and therefore require huge stirring power, also requires wear-resisting, so his stirring blades and liner is high chromium cast iron, or pieces, power is big, like JS500 will be 18.5 kw motor to drive! And the mortar is not contain coarse aggregate, so the power is very small, the power consumption is very low, do not need wear-resisting piece, appear easy and clever!

- Q: Common type of concrete mixer

- The common concrete mixer is divided into two kinds: self-falling concrete mixer and strong concrete mixer.

- Q: The safe distance of the concrete mixer

- Different devices have different requirements. But the principle is, as far as possible little, and can't always wall during operation. Therefore, maintenance convenience, give attention to two or morethings is good with 3 -- 5 mm, the thickness of the maintenance when the replacement is a flat screwdriver

- Q: Operation procedure of concrete mixer

- Before stirring, the car should be run in an empty car. Adjust the timing of the relay according to the stirring time. Water moistening the mixing bowl and the blade and the ground. The process, such as electrical or mechanical fault, should be discharged from the part of the mixing material, lighten the load, remove the fault and then drive again. When operating, the operation should be checked regularly to prevent safety accidents such as electrocution and mechanical injury. Finish the experiment, turn off the power supply, clean the mixing drum and the ground and clean up the cleaning.

- Q: For example, what is the more detailed and better td-50 td-80 td-60

- That's right, tipping over, tdcm125-6d Turn out the material JZC350 (rdcm350-6e, rdcm350-8eh, rdcm350-11e), JZC500, JZR750, JZR1000 Forced JS500, JS750

- Q: How does a concrete mixer operate

- Before the concrete mixer starts, check the controllers for good. 2, the concrete mixer must clean the inside when used, especially in the winter, no foreign material in the front roller should be used, thus extending the service life. The concrete mixer should be placed in a firm place, and shall be secured with the support of the scaffold or the support of the shaft, and shall not be supported by the tyre. When the concrete mixer is in operation, it is strictly forbidden to put the tools in the roller, and pay more attention to safety. 5, concrete mixer in the feed hopper rises, for the sake of safety, personnel are strictly prohibited by or stay under the hopper, after the completion of the work of the mixer hopper fixed; When the concrete mixer is on site, it should be fixed in the mixer, cut off the power supply, and get into the mixer cylinder In custody

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- Hello, concrete mixer is generally divided into forced (JS, JD, JW, Jacqueline Nottingham), and since the fall mixer (JZ JF) two categories, the national standard and there is JL this model, there may be enterprises themselves so named. JW only thing forced vertical turboprop mixer, mainly used in the dry rigid concrete mixing, as some concrete pipe pile and casting factory is used, but this model is old, now in the new production line is generally choose Jacqueline Nottingham vertical planetary mixer, JW stir more than sufficient.

Send your message to us

Concrete mixer JS2000 / CE & ISO Certificate

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords