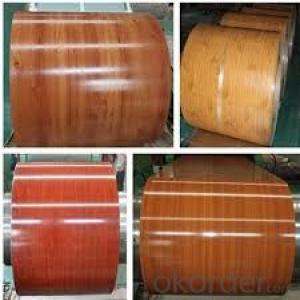

Color Steel Rolled/Printed Color Coated Sheet /Rough and Glossy Wood Grain Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Name: China PPGI manufacturer/PPGI MILL

PPGI coils

PPGI steel coils

PPGI galvanized coils

PPGI zinc coated coils

Pre-painted galvanized steel coils

Color coated steel coils

Color coated steel coils

Red color/blue color steel coils

Color coated PPGI FOR metal roof

DX51D color coated corten steel coil(PPGI)

Prime prepainted galvanized steel coil

White color prepainted steel coils

Color steel coil for roofing material

Dx51d+z prepainted steel coil

Colorful galvanized steel coil

Specifications:

Grades: Q195-Q235 and SPCC, SPCD, SPCE, SGCC (DX51D+Z) and SGCD (DX52D+Z)

Thickness: 0.13 to 2.0mm

Width: 600 to 1200mm or customized

Coil inner diameter: 508 to 610mm

Coil weight: Customized

Color: RAL

Surface protection: PE, PVDF, SMP and HDP

Surface treatment: Chromate, oil/un-oil, bright finish, spangle and anti-finger print

Standards: JIS G3302, JIS G3312 and ASTM A653M/A924M 1998

Zinc coating weight: 60 to 275G/M

Features:

Nice corrosion-resistant: Zinc layer provides nice protection of pre-painted galvanized steel sheet

High heat resistant: Reflective surface of material aids in efficiently reflecting sunlight away and turn reducing amount of heat transmitted, thermal reflectivity converts into energy-saving.

Coating adhesive force of color-coated sheet is strong, which keeps color and luster novel for long.

Widely used in such field as architecture, electrical home appliances, furniture, communal facilities, communications and transportation.

PPGI prepainted sheets and coils

Product thickness: 0.135 to 2.0mm

Product width: 760 to 1250mm

Coil weight: 5 to 10 metric tons

Coil ID: 508mm

Coil OD: Max 1500mm

Coating type: PE

Standards: JIS G 3312, ASTM A755M, GB/T 12754, Q/CHG 2-2003, EN 10143, DIN 17162

Material: TDC51D, AZ150, SGCC, CGCC, SPCC195L, TSGCC, CCGI, Q195-Q235, SPCD, SPCE

Color: RAL

Zinc coating: 60 to 275G/M²

Application: Construction, hardware, home appliances, interior decoration and more.

| NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC | |

| CERTIFICATE | ISO9001:2008 | |||

| STANDARD | EN10142 JIS G3302 GB/T-12754-2006 | ASTM A653 JIS G3302 SGCC/SGCH GB/T2518 European Standard | ASTM A792 JIS G3321 JIS G3317 | |

| GRADE | CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE | SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R | |

| MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER | |

| TYPE | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates | |

| TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc | |

| SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating | ||

| APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | |||

| SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | |||

Q&A Acceptable price term

ANSWER: FOB CNF CIF DDU CPT

- Q: How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels as they are rolled into flat sheets and then cut and shaped to form the desired body panel design. These coils provide the necessary strength and durability required for automotive body panels, ensuring that they can withstand the rigors of everyday use and provide structural integrity to the vehicle.

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- The problem with stainless steel water bottles is the steel takes even longer to decompose in our landfills then plastic its self. So it just adds to the waste. If you use steel be sure to recycle it when you are done using it. Another problem is the fact that we don't really make steel here anymore so you have to pollute the environment shipping steel here that the bottles are made from. It gets ship here on trucks, ships, and what not. Very big polluters!! You'd be better off just getting a reuseable bpa free plastic water bottle made in the usa. Or some of those expensive corn cups.

- Q: and also what makes different hardness of stainless steel?

- Stainless steel is formed due to other metals present, that are resistant to corrosion. The main one is chromium, which is an excellent protector. Hardness in steel is due to other metals, as well as the carbon content. Chromium, vanadium and tungsten make steel extraordinarily hard. High carbon content makes steel hard but brittle.

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery using various cutting methods such as shearing, slitting, or laser cutting, depending on the desired specifications and requirements.

- Q: How are steel coils used in the manufacturing of automotive fenders?

- Steel coils are used in the manufacturing of automotive fenders by being processed and shaped into the desired fender shape. The coils are first uncoiled and then sent through a series of machines that cut and shape the steel into the specific dimensions and contours required for the fender design. These shaped steel pieces are then welded or bolted together to form the final fender structure, which is later painted and installed onto the vehicle.

- Q: How are steel coils coated for color and aesthetics?

- Steel coils are coated for color and aesthetics through a process called coil coating. This involves applying a layer of paint or coating onto the steel coil surfaces, which is then cured and bonded to create a uniform and durable finish. This coating process not only enhances the appearance of the steel coils but also provides protection against corrosion and other environmental factors, making them suitable for various applications in industries such as construction and automotive.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- The manufacturing of steel furniture heavily relies on steel coils, which play a critical role. These coils, constructed from top-notch steel, act as the primary raw material for the production of various furniture items. To begin with, the framework and structure of steel furniture are created using steel coils. Manufacturers can easily cut, shape, and weld these coils into different sizes and shapes, allowing them to produce robust and enduring furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and distinctive shapes, providing both functional and aesthetic value. Additionally, steel coils are utilized to fabricate springs for furniture like sofas and chairs. The elasticity and strength of these steel coils make them ideal for crafting comfortable and supportive seating options. The coils are meticulously shaped and integrated into the furniture, ensuring that the seating surface offers the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is renowned for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture subjected to heavy use and weight load. By utilizing steel coils, the furniture can endure years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils prior to shaping them into furniture components, guaranteeing that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are a vital component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. The absence of steel coils would render the production of steel furniture impossible, compromising the quality and performance of the final products.

- Q: I know you can still but steel core ammo. I have read that it IS Armor Piercing (AP) and I have read it is not. Which is true? I am not looking for its AP capabilities. I want it if it is or is not AP. I live in Oklahoma. I need to know if it legal for me to purchase it in this state; and where can i get it? I am over 18, not a felon, etc. I have seen it sold online in Oklahoma years ago, but have read it is and isn't legal to purchase here. I am looking for 7.62x39 steel core for an SKS. If anyone knows where or how to get some, please let me know, if it's legal. Thanks.

- You can legally buy chinese steel core and 855 5.56 which is also steel core. That's on the federal level. I don't know about your state in particular but ammo peircing ammo is illegal but there are different grades of steel. If that were the case I couldn't buy Bugarian steel cased light ball in 7.62x54R.

- Q: I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

- Q: exactly what is the differance between strontuim steel and stainless steel any differances as far as hardness .... need help.

- Strontium steel is created by soaking a mild steel in strontium chromate, which has a pH of about 4 or 5, roughly the equivalent of acid rain. Chromate affects the cathodic reaction, with reduction of Cr6+ to Cr3+, and the surface film was composed of magnetite and hydrated chromium hydroxide. The Strontium is a radioactive isotope. The acid bath permeates the mild steel causing it to become mildly radioactive. Simular to oil imprengation of brass and other metals. Strontium Steel has a very high value of inhibition. However due to it's radioactive properties it is not a commonly used or manufactured material. As for where to actually obtain Strontium steel dowels. I have no idea i would speculate that you would have to purchase the raw stock and have it machined into a dowel for you.

Send your message to us

Color Steel Rolled/Printed Color Coated Sheet /Rough and Glossy Wood Grain Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords