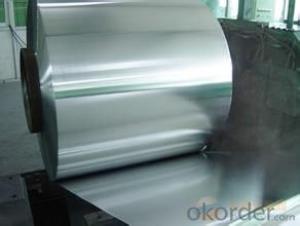

cold rolled steel coil / sheet / plate -SPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

General Application of Cold Rolled Steel Coil:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

General Application of Cold Rolled Steel Coil:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: Having a greater amount than 2% carbon in steel causes steel to suddenly become brittle. Why is this?

- Carbon fiber has better tensile capability then steel meaning its better while pulled aside. Plus you could mould the fiber to make autos-or homes-out of carbon fiber.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- steel wool = iron fibers and rusts easily in air iron + Oxygen BUT the blue soap protects the iron at first. that needs to be cleaned off. damp surfaces speed the rusting but compeletly underwater there is not much O2, ther eis some temperature has an effect. the rusting depends ofn the area of the fibers which does NOT change when you cut th epad in smaller pieces. a good beginners experiment In old times thye thought the rusted material would lose weight becasuse it was not solid iron any more careful experiments showed it gained weight and lead to and understanding of chemistry

- Q: could someone please explain to me in detail the functions of stainless steel wall ties?

- `You are not asking why they are stainless steel, but the function of wall ties. During construction of a house the wall ties start at damp proof course level. At all reveals ie doors /windows, one tie is placed on every 3rd course of bricks and 6 back from the reveal. Thereafter in the main run of brickwork 1 tie is placed every metre distance, starting at the DPC and the 6th course then the 12th and so on. They are not placed directly above each other, but in a sort of pyramid fashion. Their purpose is to hold the 2 skins of walling together, thus doubling the strength of the cavity wall in a very effective way. Stainless steel is a better quality of tie, but are not really necessary these days, because the cavity is insulated. In the old days you got condensation in the cavity and the ties rusted, and as a result of this disintegration you got bulging walls where one wall fell away from the other. Stainless steel lasted much longer because they did not rust so easily.

- Q: What are the common industry standards for steel coils?

- The common industry standards for steel coils include specifications related to dimensions, weight, chemical composition, mechanical properties, and surface finish. These standards are often set by organizations such as the American Society for Testing and Materials (ASTM), International Organization for Standardization (ISO), and the Steel Industry Associations.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using specialized equipment such as cranes or forklifts. During the loading process, the coils are carefully lifted and secured onto the ship's deck or into designated storage areas using slings or clamps. To ensure stability and prevent damage, proper balancing and securing techniques are employed. Unloading follows a similar procedure, with the coils being carefully lifted from the ship using the appropriate equipment and then transferred to trucks or storage facilities for further transportation or distribution.

- Q: What are the potential dangers of handling steel coils?

- There are numerous hazards that come with handling steel coils. To begin with, improper handling of steel coils can result in physical injuries. If not handled correctly, the weight of the coils can cause strains, sprains, or even more severe injuries. This is particularly true when using manual lifting equipment or when attempting to move the coils without proper training or assistance. Moreover, steel coils often have sharp edges or protruding parts that can lead to cuts or puncture wounds if not handled with caution. These sharp edges can be especially dangerous when manipulating or positioning the coils during transportation or storage. It is vital to wear suitable personal protective equipment, such as gloves, to minimize the risk of injury. Additionally, steel coils can become unstable if not adequately secured or balanced. Poor stacking or storage practices can result in the coils shifting or falling, potentially causing serious harm or damage. It is imperative to adhere to proper stacking and storage procedures, including the use of appropriate equipment and supports, to ensure stability and prevent accidents. Furthermore, steel coils are often stored in areas with limited space or uneven surfaces, increasing the risk of trips, falls, or collisions. It is essential to maintain clear and well-organized storage areas, free of obstacles or hazards, to reduce the likelihood of accidents. Lastly, steel coils can be susceptible to corrosion or rust, which can weaken the metal and compromise their structural integrity. This can heighten the risk of the coils collapsing or breaking during handling, potentially causing injuries or property damage. Regular inspections and maintenance of the coils, as well as proper storage in dry and well-ventilated areas, can help mitigate this risk. Overall, the potential dangers associated with handling steel coils encompass physical injuries from their weight and sharp edges, instability during transportation or storage, accidents due to limited space or uneven surfaces, and the risk of structural failure due to corrosion or rust. It is crucial to adhere to proper safety protocols, receive adequate training, and utilize the necessary equipment to minimize these risks and ensure the safe handling of steel coils.

- Q: How are steel coils used in the production of steel plates?

- The production of steel plates heavily relies on steel coils, which play a crucial role. These coils serve as the primary raw material and are vital in the manufacturing process. The initial step involves creating steel coils by heating and cooling molten steel to form thin, flat strips. These strips are then further processed in a rolling mill, where they undergo a series of rollers to decrease their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are uncoiled and straightened. This involves passing them through a machine to eliminate any curvature or deformities, ensuring that the strips are completely flat. Subsequently, the straightened coils are cut into specific lengths to match the required dimensions of the steel plates. After being cut, the coils undergo another significant step called leveling. This step involves passing the strips through a leveling machine to remove any residual stress or warping that may have occurred during the production process. Leveling guarantees that the steel plates possess a consistent thickness and are free from any distortions, making them suitable for various applications. When the leveling process is completed, the steel coils are finally transformed into steel plates. These plates can be further processed according to the desired end-use. They may undergo additional treatments like heat treatment, surface finishing, or coating to enhance their strength, durability, and resistance to corrosion. To summarize, steel coils serve as the starting point in the production of steel plates. They undergo several essential steps, including rolling, uncoiling, straightening, cutting, and leveling, to convert them into flat and uniform steel plates. These plates can then be further processed and tailored for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings by enhancing insulation and reducing heat transfer. These coils are often used in heating, ventilation, and air conditioning (HVAC) systems to efficiently regulate temperature. The coils help transfer heat effectively, allowing for better control over indoor climate and reducing the energy required for heating or cooling. Additionally, steel coils are durable and require less maintenance, making them a cost-effective solution for long-term energy efficiency in buildings.

- Q: Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in the manufacturing of appliances. They serve as a key component in various appliances such as refrigerators, washing machines, and dryers, providing structural strength and stability to the overall product.

- Q: What are the common transportation defects in steel coils?

- There are several common transportation defects that can occur in steel coils. One of the most common is coil damage caused by improper handling or securing during transportation. This can result in dents, scratches, or even tears in the steel. Another common defect is coil edge damage, which can occur if the coils are not properly protected or if they rub against each other during transit. This can lead to deformation or even breakage of the coil edges. Additionally, coil shifting is another common defect, which happens when the coils are not properly secured or braced, causing them to move and shift during transportation. This can result in misalignment or damage to the coils. Finally, coil corrosion is a common defect that can occur if the coils are exposed to moisture or other corrosive elements during transportation. This can lead to rust and deterioration of the steel. Overall, proper handling, securing, and protection measures are crucial in order to prevent these common transportation defects in steel coils.

Send your message to us

cold rolled steel coil / sheet / plate -SPCE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords