Cold Rolled Stainless Steel NO.2B Finish Grade 316L Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

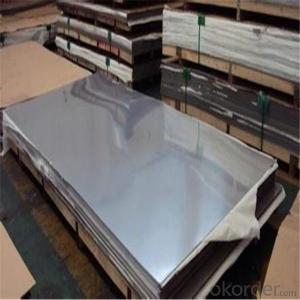

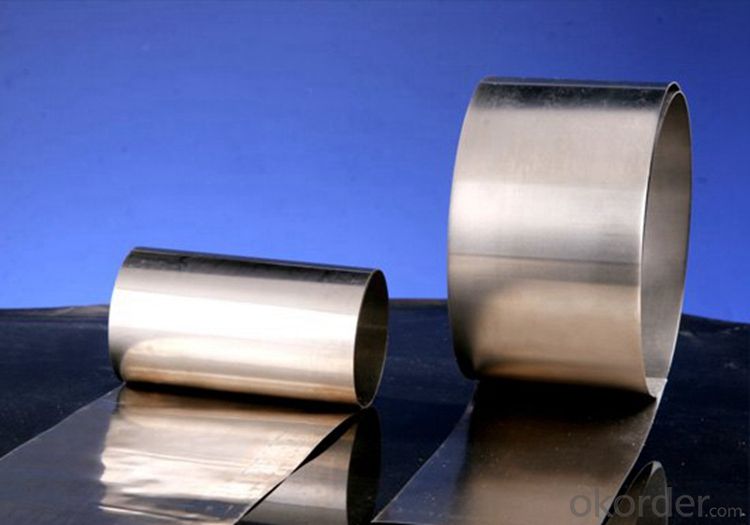

Detail picture

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Are stainless steel sheets suitable for electrical enclosures?

- Yes, stainless steel sheets are suitable for electrical enclosures. Stainless steel has excellent corrosion resistance and durability, making it ideal for protecting electrical components from environmental factors. It provides a high level of protection against water, dust, and other contaminants, ensuring the safety and longevity of the electrical enclosure. Additionally, stainless steel has good electrical conductivity, making it a suitable material for grounding purposes in electrical enclosures.

- Q: What is the cost of stainless steel sheets?

- The price of stainless steel sheets may differ based on various factors including the thickness, size, and grade of stainless steel employed. Typically, stainless steel sheets are priced per square foot or square meter. The price range can further be influenced by the supplier, location, and market conditions. Moreover, any additional processing or finishing requirements like polishing or cutting can impact the overall cost. To obtain precise and current pricing details for stainless steel sheets, it is advisable to reach out to a local supplier or distributor.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel. There are usually only six kinds of steel related to the application of building construction. They all contain 17 to 22% chromium, and better steel also contains nickel. The addition of molybdenum can further improve atmospheric corrosion, especially for atmospheric corrosion resistant chlorides.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- From the difference, the stainless steel wire drawing board is a long line, as it is covered with stainless steel plate. The polishing plate refers to a stainless steel plate with a certain brightness. The stainless steel mirror panels can be collectively referred to as glass like stainless steel mirror panels.

- Q: How do stainless steel sheets compare to other materials like aluminum or carbon steel?

- Stainless steel sheets have several advantages over other materials such as aluminum or carbon steel. Firstly, stainless steel is highly resistant to corrosion, making it suitable for applications in harsh environments or exposure to moisture. In contrast, aluminum is more prone to corrosion, while carbon steel requires additional protective coatings to prevent rusting. Moreover, stainless steel sheets offer superior strength and durability compared to aluminum, making them suitable for heavy-duty applications. Carbon steel may have similar strength properties, but it is more susceptible to corrosion and requires regular maintenance. Additionally, stainless steel sheets provide excellent heat resistance, making them ideal for high-temperature applications that aluminum may not withstand. Carbon steel can handle high temperatures, but it may be prone to oxidation if not properly protected. Lastly, stainless steel sheets have an aesthetically pleasing appearance and are available in various finishes, making them more suitable for architectural and decorative purposes compared to aluminum or carbon steel. Overall, stainless steel sheets offer a combination of corrosion resistance, strength, durability, heat resistance, and aesthetic appeal that sets them apart from other materials like aluminum or carbon steel.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel sheets. Each type has its own unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, and food processing.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- 304 and 316 stainless steel sheets are both popular choices for a wide range of applications due to their excellent corrosion resistance and durability. However, there are some key differences between the two. Firstly, the most noticeable distinction is the composition of these stainless steel alloys. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This additional molybdenum in 316 stainless steel provides enhanced resistance to corrosion, especially in chloride-rich environments such as marine or coastal areas. Therefore, 316 stainless steel is often preferred for applications where exposure to harsh conditions or corrosive chemicals is expected. Secondly, the higher nickel and molybdenum content in 316 stainless steel make it more resistant to pitting and crevice corrosion, which can occur in stagnant or low-oxygen environments. This makes 316 stainless steel a better choice for applications involving prolonged exposure to acidic or alkaline solutions, such as chemical processing plants or medical equipment. Thirdly, the higher molybdenum content in 316 stainless steel also improves its resistance to high temperatures. It can withstand higher temperatures than 304 stainless steel, making it suitable for applications involving heat exposure, such as exhaust systems or boilers. Lastly, 316 stainless steel is generally more expensive than 304 stainless steel due to its higher alloy content. However, the added benefits and increased corrosion resistance of 316 stainless steel may justify the higher cost in certain applications where performance and longevity are crucial. In summary, while both 304 and 316 stainless steel sheets offer excellent corrosion resistance, 316 stainless steel provides superior resistance to harsh environments, acidic or alkaline solutions, and higher temperatures due to its higher nickel, chromium, and molybdenum content. The choice between the two will depend on the specific application and the level of corrosion resistance required.

- Q: What are the different types of perforations available for stainless steel sheets?

- There are several types of perforations available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each type has its own unique characteristics and is suitable for different applications and aesthetic preferences.

- Q: What is the area of stainless steel plate?

- For example, a steel coil with known weight, thickness, length, width, and price, you can work out the cost price of each meter, and then you can set the price as you expect it

- Q: What are the different types of textured finishes available for stainless steel sheets?

- There are several different types of textured finishes available for stainless steel sheets, each offering a unique aesthetic appeal and functional benefits. Some of the most common textured finishes include: 1. Brushed Finish: This is the most widely used textured finish for stainless steel sheets. It is achieved through a process of brushing the surface with abrasive materials, creating a distinctive pattern of parallel lines. The brushed finish provides a smooth and elegant appearance while also masking scratches and fingerprints. 2. Embossed Finish: In this type of textured finish, a pattern is stamped onto the stainless steel sheet, creating a raised design. Embossed finishes can range from simple patterns like diamonds or squares to more complex designs. This finish adds depth and visual interest to the metal surface. 3. Bead Blast Finish: This finish is achieved by propelling fine glass beads or ceramic particles onto the stainless steel sheet at high pressure. It creates a uniform matte appearance with a slightly rough texture. Bead blasting is often used for decorative purposes, as it can give stainless steel a unique and contemporary look. 4. Linen Finish: Also known as a cross-hatch finish, the linen finish features a pattern of fine parallel lines that intersect, resembling the texture of linen fabric. This finish is achieved through a process of mechanical rolling or brushing. It provides a textured surface that is both visually appealing and resistant to scratches. 5. Satin Finish: Similar to brushed finish, the satin finish is achieved by brushing the stainless steel sheet with abrasive materials. However, the satin finish has a smoother appearance with a less pronounced pattern of parallel lines. It offers a subtle shine and a refined look, making it a popular choice for architectural and decorative applications. 6. Hammered Finish: This textured finish is created by pounding the stainless steel sheet with a ball-peen hammer or a similar tool. The result is a surface with a unique hammered pattern that adds a rustic and artisanal touch to the metal. Hammered finishes are commonly used in interior design and decorative applications. Overall, the choice of textured finish for stainless steel sheets depends on the desired aesthetic, functionality, and application. Each finish has its own distinct appearance and can enhance the visual appeal of stainless steel while also providing additional benefits such as scratch resistance and fingerprint hiding.

Send your message to us

Cold Rolled Stainless Steel NO.2B Finish Grade 316L Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords