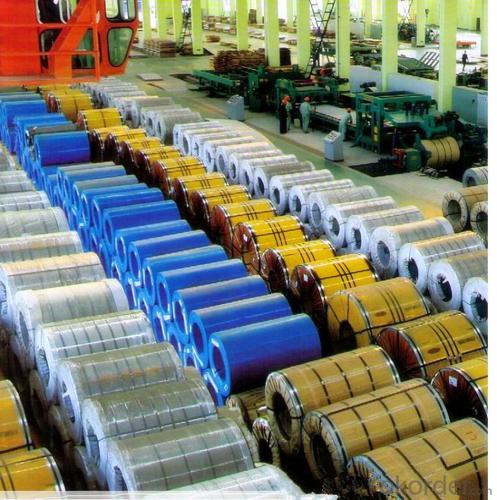

Cold Rolled Stainless Steel Coil 304 Wide/Narrow Strip 2B/BA Finish

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold Rolled Stainless Steel Coil 304 Grade Narrow/Wide 2B/BA Finish

Packaging Detail:standard export packing or as customer's requirements

Delivery Detail:7-15 days after the order

MOQ: 100mt

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | 304 | Thickness: | 0.3-3.0mm |

Place of Origin: | China Mainland | Brand Name: | CNBM | Model Number: | 304 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA |

Application: | Medical instruments, building, chemical food industry agriculture | Width: | 500-2000mm | Length: | Coil |

finish: | 2B, BA | item: | 304 cold rolled stainless steel coil | density: | 7.93 |

Cold Rolled Stainless Steel Coil 304 Grade Narrow/Wide 2B/BA Finish

Chemical composition: |

| ||||||

C | Si | Mn | Cr | Ni | S | P | |

≤0.07 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~11.0 | ≤0.03 | ≤0.035 | |

mechanical properties: |

| ||||||

Tensile strength σb (MPa) | Conditions yield strength 0.2 sigma (MPa) | Elongation δ5 (%) | Section shrinkage (%) | Hardness | |||

520 | 205 | 40 | 60 | ≤1 | |||

- Q: Are stainless steel strips prone to rusting?

- Rusting is not a common issue with stainless steel strips. Stainless steel, an alloy primarily made up of iron, chromium, and other elements, possesses properties that make it resistant to corrosion. The presence of chromium creates a protective layer on the steel's surface known as chromium oxide. This layer acts as a barrier, shielding the steel from oxygen and moisture and preventing the formation of rust. However, certain circumstances, such as exposure to chlorides, acids, or high humidity environments, can still lead to corrosion or staining of stainless steel. Therefore, even though stainless steel strips are highly resistant to rust, it is still necessary to take proper care and maintain them to ensure their durability.

- Q: Can stainless steel strips be used for heat sinks?

- Yes, stainless steel strips can be used for heat sinks. Stainless steel has good thermal conductivity, which allows it to transfer heat efficiently. Additionally, stainless steel is resistant to corrosion, making it a durable option for heat sink applications. However, it is important to note that stainless steel has lower thermal conductivity compared to materials like copper or aluminum, which are commonly used for heat sinks. Therefore, stainless steel strips may not be as effective as other materials in dissipating heat in high-power applications.

- Q: Can stainless steel strips be used in electronics applications?

- Yes, stainless steel strips can be used in electronics applications. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it suitable for various electronic components and applications. It is often used in the manufacturing of connectors, terminals, springs, battery contacts, and shielding, among others. Stainless steel strips can provide electrical conductivity, thermal stability, and resistance to vibration and mechanical stress, making them reliable for use in electronic devices. Additionally, stainless steel is non-magnetic, which can be beneficial for certain applications where magnetic interference needs to be minimized.

- Q: Can stainless steel strips be used for food storage containers?

- Yes, stainless steel strips can be used for food storage containers. Stainless steel is a popular choice for food storage containers due to its durability, resistance to corrosion, and its ability to prevent the transfer of odors and flavors. It is a safe and hygienic material that does not react with acidic or alkaline foods, making it suitable for storing a wide range of food items.

- Q: What are the different types of finishes available for stainless steel strips?

- There are several types of finishes available for stainless steel strips, each offering unique characteristics and aesthetic appeal. Some of the most common finishes include: 1. No.1 Finish: This is the most basic and rough finish, also known as hot-rolled annealed and pickled (HRAP). It has a matte appearance with visible grain lines and is commonly used for industrial applications. 2. No.2B Finish: This finish is achieved by cold rolling the stainless steel strip after pickling and annealing. It has a smooth, reflective surface with a moderately shiny appearance. No.2B finish is widely used in architectural, kitchen, and equipment applications. 3. No.2D Finish: This finish is similar to No.2B, but it is achieved by cold rolling the strip further to achieve a smoother finish. It has a slightly duller appearance than No.2B and is commonly used for deep-drawn applications. 4. No.3 Finish: Also known as a ground finish, this finish is achieved by polishing the stainless steel strip using abrasives. It has a semi-reflective appearance with a uniform grain pattern and is often used for architectural and decorative applications. 5. No.4 Finish: This is a popular finish for stainless steel strips as it combines a polished appearance with excellent corrosion resistance. It is achieved by further polishing the strip after No.3 finish, resulting in a smooth, brushed appearance. 6. No.6 Finish: This finish is achieved by polishing the stainless steel strip using finer abrasives, resulting in a higher level of reflectivity and a mirror-like appearance. It is commonly used for decorative and architectural applications. 7. No.7 Finish: This finish is similar to No.6 but with an even higher level of reflectivity. It is achieved by using even finer abrasives during the polishing process. No.7 finish is often used for decorative purposes or in high-end architectural projects. 8. No.8 Finish: Also known as a mirror finish, this is the highest level of reflectivity available for stainless steel strips. It is achieved by using extremely fine abrasives during the polishing process. No.8 finish is commonly used for decorative applications, such as in furniture and automotive trim. These are just a few of the many finishes available for stainless steel strips. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: How does the thermal conductivity of 111 stainless steel strips compare to other materials?

- Compared to other materials, the thermal conductivity of 111 stainless steel strips is generally lower. When compared to metals like copper or aluminum, stainless steel is not an efficient conductor of heat. However, among the stainless steel family, the 111 grade may exhibit slightly higher thermal conductivity than other grades. Nevertheless, it remains lower than many commonly used materials. For applications that demand high thermal conductivity, materials like copper or aluminum, which possess superior thermal conductivity properties, would be more appropriate.

- Q: Are stainless steel strips suitable for jewelry making?

- Yes, stainless steel strips are suitable for jewelry making. Stainless steel is a durable and versatile material that is resistant to tarnishing, rust, and corrosion, making it an excellent choice for jewelry that is meant to last. It is also hypoallergenic, making it suitable for individuals with sensitive skin or metal allergies. Stainless steel strips can be easily shaped and manipulated into various jewelry designs, including rings, bracelets, necklaces, and earrings. Additionally, stainless steel is often used as an alternative to more expensive metals like silver or gold, offering a more affordable option for those who still desire high-quality jewelry.

- Q: Can stainless steel strips be formed into coils or rolls?

- Yes, stainless steel strips can be formed into coils or rolls. The flexibility and ductility of stainless steel allow it to be easily shaped and rolled into various coil or roll forms for different applications.

- Q: Do you have stainless steel with magnetic?

- Ferritic stainless steel is generally magnetic, austenitic stainless steel is generally non-magnetic. So we can't generalize.

- Q: Can stainless steel strips be used in medical instrument manufacturing?

- Indeed, the utilization of stainless steel strips is applicable in the manufacturing of medical instruments. The medical industry frequently opts for stainless steel as a material of choice due to its exceptional characteristics, such as its resistance to corrosion, formidable strength, and ability to withstand high temperatures. These properties render stainless steel strips highly suitable for an extensive array of medical instruments, encompassing surgical tools, dental implements, implantable devices, and diagnostic apparatuses. Moreover, stainless steel possesses the added advantage of being effortlessly cleaned and sterilized, a vital requirement in upholding a sterile environment within medical facilities. Consequently, stainless steel strips are extensively employed in the manufacturing of medical instruments owing to their robustness, dependability, and hygienic attributes.

Send your message to us

Cold Rolled Stainless Steel Coil 304 Wide/Narrow Strip 2B/BA Finish

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords