Cold drawn precision seamless carbon steel pipe astm sa106

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of seamless carbon steel pipe:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of seamless carbon steel pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、seamless carbon steel pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of seamless carbon steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

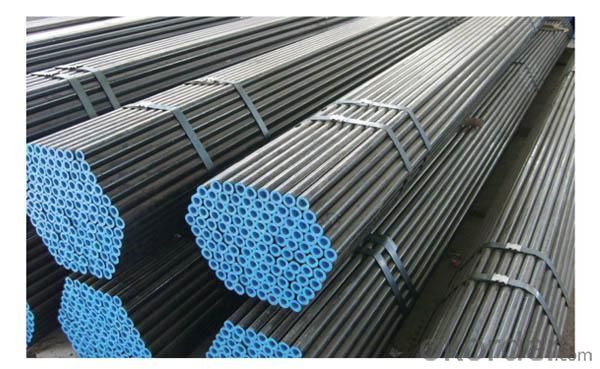

6、seamless carbon steel pipe Images:

- Q: Can steel pipes be used for conveyor systems?

- Yes, steel pipes can be used for conveyor systems. Steel pipes are known for their strength, durability, and resistance to wear and tear, making them suitable for handling heavy loads and continuous operation in conveyor systems. Additionally, steel pipes can be easily welded, allowing for customization and flexibility in conveyor designs.

- Q: What are the different methods of pipe lining for steel pipes?

- There are several different methods of pipe lining for steel pipes, each with its own unique features and benefits. These methods include: 1. Spray lining: In this method, a specially formulated coating is sprayed onto the interior surface of the steel pipe. The coating adheres to the pipe and forms a protective barrier against corrosion and chemical damage. Spray lining is relatively quick and cost-effective, making it a popular choice for smaller diameter pipes. 2. Cured-in-place pipe lining (CIPP): CIPP involves inserting a flexible liner into the steel pipe and then curing it in place using steam or hot water. This method creates a seamless and durable lining that restores the structural integrity of the pipe. CIPP is commonly used for larger diameter pipes and can be installed without the need for excavation. 3. Slip lining: Slip lining involves inserting a slightly smaller diameter pipe into the existing steel pipe. The annular space between the two pipes is then grouted or filled with a cementitious material. This method is effective in rehabilitating pipes with minor defects or damages and can significantly increase the pipe's lifespan. 4. Fold-and-form lining: In this method, a flexible liner is inserted into the steel pipe and then expanded to the pipe's diameter using a mechanical or hydraulic process. The liner is then folded and formed to fit the contours of the pipe before being cured in place. Fold-and-form lining is ideal for pipes with irregular shapes or bends. 5. Coating lining: Coating lining involves applying a protective coating to the interior surface of the steel pipe. The coating can be sprayed, brushed, or rolled onto the pipe's surface and provides a barrier against corrosion and chemical damage. This method is commonly used for large diameter pipes or pipes in harsh environments. Each of these methods has its own advantages and disadvantages, and the choice of the lining method will depend on factors such as pipe diameter, condition, budget, and project requirements. It is important to consult with a professional pipe lining contractor to determine the most suitable method for a specific steel pipe rehabilitation project.

- Q: Can steel pipes be used for conveying chemicals?

- Yes, steel pipes can be used for conveying chemicals. Steel is a strong and durable material that can withstand high pressure and temperature conditions, making it suitable for transporting various chemicals. Additionally, steel pipes have excellent resistance to corrosion, which is crucial when dealing with corrosive substances. They are commonly used in industries such as oil and gas, chemical processing, and water treatment where the safe and efficient transport of chemicals is essential. However, it is important to consider the specific requirements of the chemical being conveyed and ensure that the steel pipe is compatible with it. Proper material selection, including the use of corrosion-resistant coatings or linings, may be necessary to prevent any adverse reactions between the chemicals and the steel pipe.

- Q: How do you calculate the pipe head loss for steel pipes?

- To calculate the pipe head loss for steel pipes, you can use the Darcy-Weisbach equation. This equation relates the head loss (hL) to the flow rate (Q), pipe diameter (D), pipe length (L), fluid density (ρ), fluid velocity (V), and a friction factor (f). The formula is as follows: hL = (f * (L/D) * (V^2))/(2g) Where: - hL is the head loss (measured in meters) - f is the friction factor (dimensionless) - L is the pipe length (measured in meters) - D is the pipe diameter (measured in meters) - V is the fluid velocity (measured in meters per second) - g is the acceleration due to gravity (usually taken as 9.81 m/s^2) The friction factor (f) depends on the Reynolds number (Re) of the flow, which is a dimensionless quantity representing the ratio of inertial forces to viscous forces. The Reynolds number can be calculated as: Re = (ρ * V * D) / μ Where: - Re is the Reynolds number (dimensionless) - ρ is the fluid density (measured in kg/m^3) - V is the fluid velocity (measured in meters per second) - D is the pipe diameter (measured in meters) - μ is the dynamic viscosity of the fluid (measured in Pa·s or N·s/m^2) The friction factor (f) can be obtained from empirical correlations or from Moody's diagram, which relates it to the Reynolds number and the relative roughness of the pipe surface. By substituting the calculated friction factor (f) and other known values into the Darcy-Weisbach equation, you can determine the head loss in the steel pipe. It is important to note that the head loss is a measure of energy loss due to friction and other factors, and it is typically expressed in terms of pressure drop or height difference.

- Q: What's the difference between straight steel pipe and seamless steel pipe?

- The welded pipe is made of rolled steel plates, and small ones are straight welded, and big ones are spiral welded. Because the welded pipe has weld, the mechanical performance of weld is poor, so its applicable range is limited, but its price is cheap. Significant difference is that there are welded pipe, seamless steel pipe is not, of course, the welded pipe treatment of good, layman do not see the difference.

- Q: Can steel pipes be used for conveying natural gas?

- Yes, steel pipes can be used for conveying natural gas. In fact, steel pipes are commonly used for this purpose due to their strength, durability, and ability to withstand high pressures. Steel pipes also have excellent resistance to corrosion, which is crucial when transporting natural gas that contains impurities like water and sulfur compounds. Additionally, steel pipes can be easily welded, making them ideal for connecting different sections of the pipeline. Overall, steel pipes are a reliable and safe choice for conveying natural gas.

- Q: What is the difference between standard wall thickness and extra-strong wall thickness steel pipes?

- The main difference between standard wall thickness and extra-strong wall thickness steel pipes lies in their thickness and durability. Standard wall thickness pipes have thinner walls and are suitable for most general applications, while extra-strong wall thickness pipes have thicker walls and are designed for heavy-duty or high-pressure applications. These extra-strong pipes offer enhanced strength and resistance, making them more reliable and suitable for handling extreme conditions or demanding projects.

- Q: How are steel tubes represented?

- If you speak of steel pipe, if it is water. Gas transmission pipe, then it is said: nominal diameter refers to the inner diameter. The units are millimeters or inches. [for example, water pipes with phi 25. It means that the nominal diameter (diameter) is 25mm (or an inch) steel pipe.

- Q: What is PE coated steel pipe? Seek explanation

- PE pipe is a kind of thermoplastic resin with high crystallinity and non polarity.

- Q: What are the factors affecting the price of steel pipes?

- The price of steel pipes can be influenced by various factors. These factors encompass: 1. Raw material expenses: The cost of raw materials like iron ore and coal significantly influences the price of steel pipes. Fluctuations in commodity prices can impact the overall production cost and subsequently affect the selling price. 2. Supply and demand dynamics: The price of steel pipes is determined by the interplay of supply and demand. When there is high demand and limited supply, prices tend to rise. Conversely, an oversupply and low demand can lead to price decreases. 3. Production and manufacturing costs: The direct impact of production and manufacturing expenses on steel pipe prices cannot be overlooked. Costs related to labor, energy, transportation, and equipment maintenance all contribute to the overall production cost and, consequently, the selling price. 4. Market competition: The level of competition within the steel pipe industry also influences prices. Increased competition among manufacturers and suppliers can result in more competitive pricing. Conversely, fewer competitors may lead to higher prices due to limited options. 5. Government policies and regulations: Government policies and regulations exert a significant influence on steel pipe prices. Import tariffs, trade restrictions, and environmental regulations can all affect production costs and subsequently impact prices. 6. Currency exchange rates: Currency exchange rates can also sway steel pipe prices. Fluctuations in exchange rates between countries can impact the cost of importing or exporting steel pipes, which in turn affects their selling price. 7. Global economic conditions: The overall state of the global economy can have repercussions on steel pipe prices. During periods of economic growth, demand for steel pipes may increase, leading to higher prices. Conversely, economic downturns can result in decreased demand and subsequently lower prices. It is vital to acknowledge that these factors can interact and fluctuate over time, making the pricing of steel pipes a complex and ever-changing process.

Send your message to us

Cold drawn precision seamless carbon steel pipe astm sa106

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords