CNBM Cold Rolled 201 Stainless Steel Coil,304 Stainless Steel Coil,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

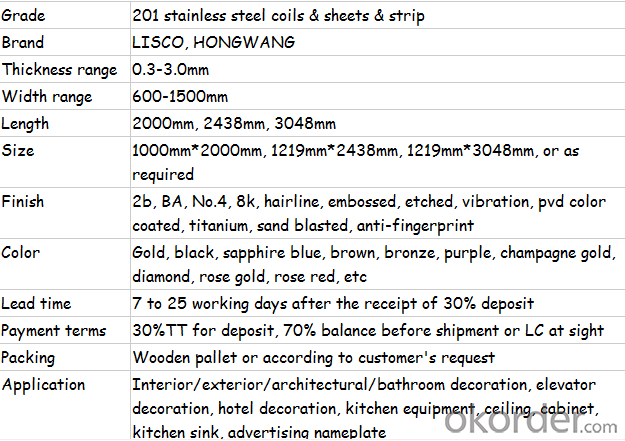

1,the specification of the cold rolled 201 stainless steel coil,304 stainless steel coil,430 stainless steel coil

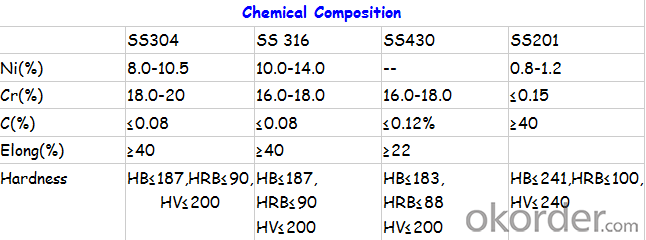

2,the chemical composition of the cold rolled 201 stainless steel coil,304 stainless steel coil,430 stainless steel coil

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,our related products

5,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: How do steel coils contribute to acoustic performance in buildings?

- Steel coils can contribute to acoustic performance in buildings by providing a solid structure that reduces vibrations and sound transmission. The use of steel coils in construction helps dampen noise by absorbing and dissipating sound waves, resulting in a quieter and more comfortable indoor environment.

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including polyester, polyurethane, siliconized polyester, fluorocarbon, and plastisol coatings. Each type of coating offers specific properties and benefits, such as durability, corrosion resistance, weatherability, and aesthetics, making them suitable for various applications in industries such as construction, automotive, and appliances.

- Q: i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- DO NOT PUT ACOUSTIC (steel) STRINGS ON A CLASSICAL GUITAR. Classical guitars are not built to withstand the tension of steel strings. putting steel strings on a classical guitar can cause irreparable damage to the neck, where the neck joins the body and the heel. Classical guitars have nylon strings. Yes 3 of them look like steel strings, but these are actually metal wrapped around a nylon core. Acoustic guitars are metal strings. The wound strings on an acoustic have a metal string core. Classical guitars tend to have a wider neck and are more for classical music, flamenco, finger picking, etc. Acoustic guitars can have lower tension strings put on them (e.g. martin silk and steel) as the guitar can be adjusted to take the lighter string tension placed on the neck and heel. Martin Silk and Steel Strings can also be put on a classical guitar as they have a lot lower tension than steel and they give a louder more acoustic sound.

- Q: Don't ask me why, but I took my stainless steel ring and I heated it up with my gas stove. I stuck it in there til the metal turned red, and the flame which is normally blue turned orange for some reason when the metal turned red. Anyway, afterwards i cooled it off in water and now it's all discolored and it feels different. It's weighs less and it doesn't feel the same. Plus, it's ugly cause it's all black and blue. What happened? Someone help

- Stainless steel has a rating. I don't know what your ring's stainless steel rating is. If you know, you can look it up. The rating will tell you how much steel vs other metal it has (usually Cr and Ni). But usually when you heat the stainless steel to extreme temperature it will discolor due to oxidation. What is worse is that you cooled it off in water (I assumed that you did it while it was still hot). By rapid cooling, you have changed the physical structure of the steel itself. It will change the hardness of the steel. That is why it feels different. Look up on annealing, normalizing, quenching and tempering under heat treatment for steel.

- Q: Is steel framing eco friendly? Why or why not.

- Most of it is made from recycled iron and steel. You can also climb a ladder carrying a dozen steel studs far easier than you can lumber studs. It is this latter part why it is so popular in some areas.

- Q: How are steel coils protected from chemical damage?

- Steel coils are typically protected from chemical damage through various methods such as applying protective coatings or using barrier films. These protective measures act as a barrier between the steel surface and any potentially corrosive chemicals, preventing direct contact and minimizing the risk of chemical damage.

- Q: What are the different types of steel coil slitting processes?

- There are several different types of steel coil slitting processes, each with its own benefits and considerations. Here are some of the most common types: 1. Rotary slitting: This is the most traditional and widely used slitting process. It involves a rotating circular blade that cuts through the coil. Rotary slitting is highly precise and can produce narrow strips, making it suitable for a wide range of applications. 2. Loop slitting: In this process, the coil is fed through a loop before being cut. Loop slitting allows for high-speed processing and can handle thicker materials. It is commonly used for heavy-duty applications and large coils. 3. Drag slitting: Also known as shear slitting, this process uses a stationary blade that pulls the material through to make the cut. Drag slitting is suitable for thinner materials and offers a high-quality edge finish. 4. Crush slitting: This process involves pressing the material between two rollers to make the cut. Crush slitting is commonly used for delicate materials that require a gentle cutting action. It can produce clean cuts and minimize burrs. 5. Laser slitting: As the name suggests, this process uses a laser beam to cut through the coil. Laser slitting offers high precision and can handle a wide range of materials. It is particularly useful for specialty steels and thin strips. Each type of steel coil slitting process has its own advantages and limitations, so it's important to consider factors such as material thickness, coil size, and required strip width when choosing the appropriate method. Additionally, factors like cost, speed, and edge finish should also be taken into account to determine the best process for a specific application.

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first cleaning and removing any contaminants from the surface. Then, they are shredded into smaller pieces and melted down in a furnace. The molten steel is then formed into new coils or other steel products. This process helps conserve natural resources, reduces energy consumption, and minimizes waste.

- Q: for a roof spanning 14.4m x 8.4m on a residential house, is it better to use timber trusses or steel trusses? the priorities are; ease of construction, price, insulation (want to keep heat out, i am in a tropical country), durability, flexibility, minimal load on foundations.please help. thank you :-)

- U will to find details on metal trussesin constructing materials AND development through BINDRA AND ARORA and u may additionally to find them in MCKAY(B.M.C).About steel doors and windows search the net u can search in google or yahoo u will to find it . Ok bye bye all of the exceptional.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

Send your message to us

CNBM Cold Rolled 201 Stainless Steel Coil,304 Stainless Steel Coil,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords