Cmax TC12 Self-Propelled Crane Telescopic Crawler Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

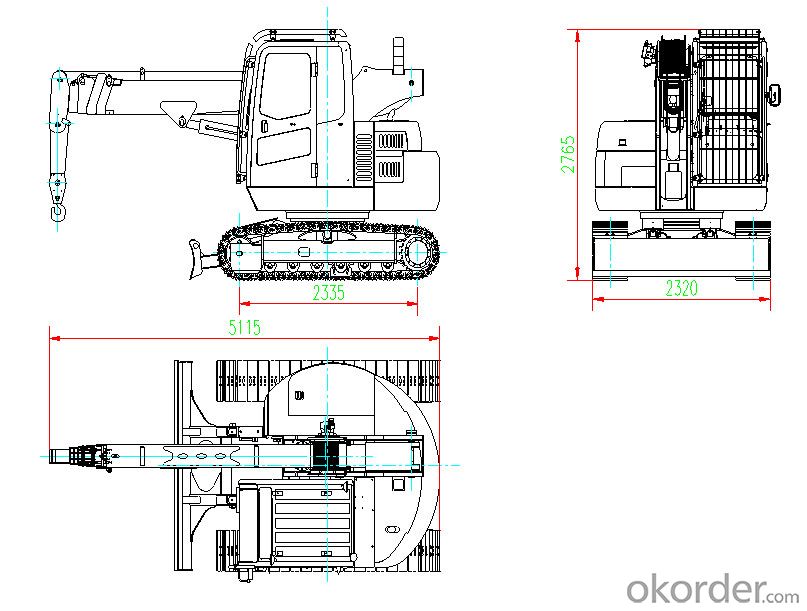

Cmax Self-Propelled Crane Telescopic Crawler Crane

Telescopic crawler crane is a self-propelled crane. Crawler belt ground contact area is bigger. Traffic ability characteristic and the adaptability are good. It is applicable to the operation site in uneven areas, such as oil field, mining area, construction site, freight depot, wharf and other construction site; especially the low specific pressure area of wetland type area, such as marsh; and desert area that the wheel crane and others can’t work normally. This crane can play its special performance better in the area. The crane is mainly used for hoisting, load and unload, and short distance driving on load of construction machinery. And it also can make the laying into the ditch, docking, installation and repair of pipelines. It can be used in petroleum, chemical, mining, city construction, water conservancy and other large-scale projects. Meanwhile, it can be used as a general hoisting machinery for cargo loading and unloading, hoisting, stacking, equipment installation work, etc.

Cummins engine, it can provide economic, environmentfriendly and reliable power source, the cover is convenient to open and easy to maintain.

High strength steel plate, large fillet, polygon boom, good rigidity, light weight, strong bearing capacity and reliable performance, imported force limiter, all-direction monitoring operation and high safety performance.

Shock absorption connection is equipped with the fully enclosed operator cabin, high class shock absorption chair,cooling and heating air conditioner, 10-gear electronic gasoline throttle with wide field of view and comfortable to operate.

Japan KYB motor and reducer, lengthened chassis, capable of being equipped with triangle track-shoe as optional, strong driving force, capable of adapting to ground construction under various conditions.

| Type | SWTC12 | |||

|---|---|---|---|---|

| Size | Size(L W H) | mm | 11.88×3.19×3.06 | |

| A | Track base | mm | 3653 | |

| B | Crawler length | mm | 4560 | |

| C | Ground clearance of platform | mm | 1140 | |

| D | Tail swing radius | mm | 3470 | |

| E | Chassis width | mm | 3190 | |

| F | Track width | mm | 800 | |

| G | Min. ground clearance | mm | 478 | |

| H | Track height | mm | 906 | |

| I | Overall length | mm | 11880 | |

| J | Overall height | mm | 3060 | |

| I | Overall width | mm | 3190 | |

| Parameters | Max. lifting load | T | 12 | |

| Max. torque of basic boom | kN-m | 408(102kN×4m) | ||

| Max. arm force of full extending boom | kN-m | 273(42kN×6.5m) | ||

| Length of basic boom | m | 9 | ||

| Length of full extending boom | m | 16 | ||

| Max. lifting height of basic boom | m | 9.1 | ||

| Max. lifting height of full extending boom | m | 16.2 | ||

| Work Parameters | Boom rising / Descending time | s | 40/20 | |

| Boom extending / Retracting time | s | 80/50 | ||

| Slewing speed | rpm | 3.2 | ||

| Max. line speed | m/min | 102 | ||

| Traveling speed | km/h | 4.9 | ||

| Total weight | T | 20 | ||

| Gradeability | ° | 20 | ||

| Ground pressure | kPa | 32 | ||

| Engine | Brand | - | Cummins | |

| Model | - | 6BT5.9-C150 | ||

| Operation type | - | SVTCOH12/1 Water cooled / Turbol | ||

| Displacement | L | 5.9 | ||

| Power/Speed | kW/rpm | 110/2300 | ||

| Full tank capacity | L | 310 | ||

FAQ

Advantage & Application

1.Chinese Cummi.ns intercooled& turbocharged diesel engine;

2. Integral torque converter and gearbox(Germany ZF technology);

3. Driving axle with built-in free-wheel anti-slip differential;

4. Heavy-duty roller chains transmission balance box;

5.Popular swing-arm connecting rod operating mechanism;

6. Free-maintenance rolling-disc rotary device;

7. Double cylinders control the balde cutting angle;

8.Two sets of imported control valve (HUSCO Brand);

9. Imported hydraulic balancing valve for the blade lifting;

10. Steering system:center articulated mechanism and tilting front wheels to achieve crab-style movement;

11. Electro-hydraulic control: instrumentation monitoring & maintenance-free valta battery;

- Q: How is the length of the main hoist's main winch and sub-winch wire rope calculated?

- When the lifting angle of the boom is maximum, the wire rope override (generally not the full magnification of the main hook) is specified according to the specifications of the crane, and the length of the main rope is the length of the main rope.

- Q: What are the safety procedures for truck cranes?

- 4, new, repair and new installation of lifting machinery and equipment, should be in accordance with the "Construction Machinery Technical Test Procedures" in the relevant provisions of the test and test hanging, and after the competent crew, operators and security departments to check, qualified rear

- Q: What is the difference between a truck crane and a truck crane?

- Tonnage truck cranes will be replaced by the performance of advanced, full-featured large tonnage truck crane.

- Q: What operating permits are required for truck cranes?

- 2, the car crane driver must also be made by the company issued by the internal quasi-driving license;

- Q: What is the speed limit of a motor vehicle crane?

- The role of the balance valve can not only lock, but also speed limit.

- Q: How to get the weight of the truck crane

- The crane center of gravity is not provided nor is it obtained,

- Q: What are the four kinds of truck cranes?

- the boom of the boom (the elevation angle of the adjustment boom), the horizontal cylinder of the leg and the vertical cylinder of the leg.

- Q: What is the reason for the jitter of the crane boom

- Damping holes, damping holes once blocked, the balance valve will lose its role, causing the boom when the telescopic jitter.

- Q: What are the daily maintenance of the truck crane?

- Responsible for tracking the progress of the equipment delivered by the equipment manufacturer or agent to ensure that the equipment is on time.

- Q: What is the material of the truck crane wheel?

- 2, nylon pulley material for the engineering plastics - nylon-made crane pulley has a good technical performance, about to improve the life of the pulley 4 to 5 times and wire rope life 10 times.

Send your message to us

Cmax TC12 Self-Propelled Crane Telescopic Crawler Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords