Plastic Tubes - Industrial & Agricultural Grade China PP-R Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe

Advantages

1.We named this kind of fittings as PPR reducing sleeve. ppr reducing coupling

2.A whole part of this PPR reducing sleeve is made of polypropylene.

3.As you know, all the fitting designed for connecting the pipe or change the piping path. This PPR reducing sleeve is able to connect the different diameter pipeline together. I believe you know how to use it.

4.All of these PPR pipe fitting come in 3 different colors: white, gray, green.

5.Our PPR pipe fitting had been pasted the ISO9001 authentication. And had been got the CE certification.

6.These PPR reducing sleeve makes use of completely 100% new PPR material import from Korea. To be ensured that it is much healthier than the pipe make use of the reclaim plastic.

7.We adopt the newest technology in the piping produce industry.

8.We had been piping manufacturer for over 10 years. And we are good at this.

Product Description

Pressure | Size(mm) | Pressure | Size(mm) |

PN1.25MPA | 20*2.0 |

PN1.6MPA | 20*2.3 |

25*2.3 | 25*2.8 | ||

32*2.9 | 32*3.6 | ||

40*3.7 | 40*4.5 | ||

50*4.6 | 50*5.6 | ||

63*5.8 | 63*7.1 | ||

75*6.8 | 75*8.4 | ||

90*8.2 | 90*10.1 | ||

110*10.0 | 110*12.3 |

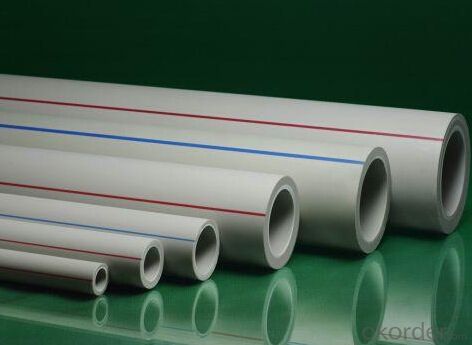

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Are plastic tubes suitable for beverage dispensing?

- Yes, plastic tubes are suitable for beverage dispensing. They are commonly used in the food and beverage industry due to their durability, flexibility, and resistance to chemical reactions with various liquids. Plastic tubes also offer ease of cleaning and maintenance, making them a practical choice for beverage dispensing systems.

- Q: Can plastic tubes be customized with logos or labels?

- Yes, plastic tubes can be easily customized with logos or labels. This can be done through various methods such as printing, engraving, or attaching labels onto the tubes. Customizing plastic tubes with logos or labels helps businesses to enhance their branding and product identification.

- Q: Can plastic tubes be used in high-pressure applications?

- Yes, plastic tubes can be used in high-pressure applications, but it depends on the specific type of plastic used and the pressure level required. Certain types of plastic, such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), and polypropylene (PP), have good resistance to pressure and can withstand high-pressure environments. However, it is important to consider factors like temperature, chemical compatibility, and the specific requirements of the application when selecting plastic tubes for high-pressure use.

- Q: Can plastic tubes be used for DIY hydroponics systems?

- Yes, plastic tubes can indeed be used for DIY hydroponics systems. They are commonly used as channels to deliver nutrient-rich water to the plants' roots and can be easily customized to fit different setups. Plastic tubes are lightweight, durable, and readily available, making them a practical and affordable choice for constructing hydroponics systems at home.

- Q: Can plastic tubes be used for sound insulation?

- Yes, plastic tubes can be used for sound insulation. Plastic tubes can be filled with sound-absorbing materials such as foam or rubber, which help to reduce the transmission of sound waves. Additionally, the use of plastic tubes can provide a barrier that prevents sound from passing through, making them an effective option for sound insulation in certain applications.

- Q: What are the advantages of using plastic tubes in packaging?

- There are several advantages of using plastic tubes in packaging. Firstly, plastic tubes are lightweight, making them easy to transport and handle. Secondly, they are durable and provide excellent protection for the contents inside, preventing damage or breakage. Additionally, plastic tubes are resistant to moisture and can be made airtight, ensuring the products inside remain fresh and uncontaminated. Furthermore, plastic tubes offer flexibility in design and can be customized to suit various shapes, sizes, and labeling requirements. Lastly, plastic tubes are cost-effective compared to other packaging materials, making them a popular choice for many businesses.

- Q: I have a pond pump and standard aquarium plastic tubing. I will be drilling tiny holes in equal increments throughout the tubing to release the air. Is there an equation to show the air pressure that will be released through the holes? I would like to know how many holes I need and how far to space them to achieve a certain amount of air pressure to be released from a specified length of tubing.This is a test and will not be done under water. A simple diffuser will not work for this application.Ideally I would like a formula where I can input the following and get a result:Tube LengthTube DiameterPump PSITube Hole SizeTube Hole QuantityTube Hole SpacingResultAirflow per Tube HoleAny help would be greatly appreciated. If you need more information please let me know.Thank you,

- Well, I suppose it could be done, but you would need the pressure at each hole,which is decreasing as the tube length and water depth. And you have so many variables! I also like to calculate such things as you are doing, but this is really over the top! Here is what I would do; Get a measured paper cup (say 1 cup, or 1/4 litre). Experiment with various sizes and number of holes in your tubing, then hold the cup over the coiled tubing, under water at required depth, with air pump running. Measure the time to fill the inverted cup with air. If a 1/4 litre container fills with air in 15 seconds (1/4 minute), you know you are getting 1 litre per minute. Then try other hole configurations to get what you want. This would be more fun, more practical, and will give bettter results. Good luck Bill

- Q: Also if this isn't safe then how unsafe was it when some kid spilled a whole container of mercury on the floor in my class and started playing with it. Ya anyway i would never touch it.

- Your Hg is safe in the tube and MUCH safer than some kid plating with it with his fingers. The expression Mad as a Hatter comes from olden days when the felt on hats was applied with a mercury paste by workers using their hands

- Q: How are plastic tubes manufactured?

- Plastic tubes are manufactured through a process called extrusion. In this process, plastic pellets or resin are melted and forced through a die, creating a continuous tube shape. The tube is then cooled, cut into desired lengths, and may undergo additional processes such as printing, labeling, or sealing before being packaged.

- Q: Are plastic tubes suitable for use in the textile industry?

- Yes, plastic tubes are suitable for use in the textile industry. They are commonly used for various purposes such as storing and transporting fabrics, yarns, and other textile materials. Plastic tubes offer durability, flexibility, and protection to the textiles, making them an ideal choice for the industry.

Send your message to us

Plastic Tubes - Industrial & Agricultural Grade China PP-R Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords