China concrete expansion joint material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

CAS No.: 111

Other Names: High Elastic Crack Sealing Joint

MF: AAA

EINECS No.: AAA

- Classification: Hot Melt Adhesives

Main Raw Material: Other

Usage: Construction

hot searching word: concrete expansion joint material

keywords: waterproof adhesive

Softening point℃: 98

5 degree Ductility℃: 45

Recovery %: >90%

Flash point %: >300

Modifying agent ratio: >15

Advised base materials temperature: -25-45 degree

Advised working: 160-180℃

Advised heating up temperature: 180-200℃

Packaging & Delivery

| Packaging Details: | in boxes |

|---|---|

| Delivery Detail: | About 10 days after receive payment |

Specifications

concrete expansion joints

adhesives waterproof

China crack seal

cracks sealant

China concrete expansion joint material

Product Description

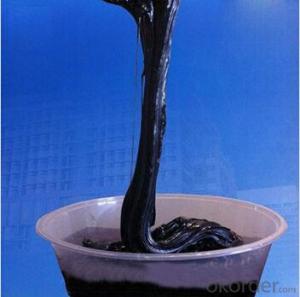

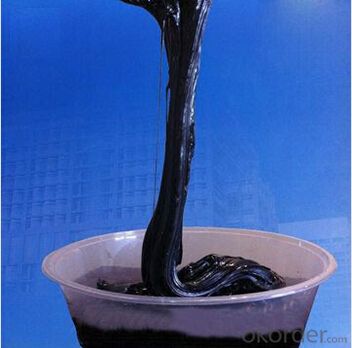

High elastic concrete joints sealant is mainly composed of modified asphalt, natural rubber and synthetic polymer materials with a certain craft. It is an ideal concrete joints sealed- waterproof material which has reached the international advanced level.

It can be widely applied to:

Seal the sawcutting joints and perimeter joints in asphalt concrete pavement, cement concrete road, and also use for sealing Highspeed road, bridge road and airport runways 's expansion joints, cutting joints, reserved joints, peripheral joints. marble adhesive

All kinds of road surface crack repair irrigation and sealed- waterproof.

Seal the joints and prevent water permeation in the precast concrete panels of the building roof.

Main Properties and Characteristics

a.Super elastic recovery function, high resistance to fatigue strength, and good resistance to sands.

b.Keep good flexibility in low temperature and stability in high temperature. Adapting to the high temperature and the low temperature environment.

c.High cementing performance, remarkable waterproof effect.

d.Super resistance to eroding , and outstanding resistance to water, acid, alkali and oil.

e.Elongation rate is as high as 560%, good toughness, super anti-seismic capability.

f.Prolonging the life of the road and bringing down the cost of maintenance remarkable.

Standards

COST-1266 is complying with American Standard ASTM-1190.

Technical Data

Item | Test Result | Test Method |

Penetration/ 0.1mm | 36 | ASTMD—1190 |

Softening point /°C | 98°C | ASTMD—36 |

5°C Ductility | 45 | ASTMD—113 |

Recovery / % | >90% | T0662 |

Flash point /°C | >300 | T0611 |

Modifying agent ratio | >15% | |

Advised base materials temperature | -25°C—45°C | |

Advised working & sealing temperature | 160°C—180°C | |

Advised heating up temperature | 180°C—200°C | |

Application Adding Method

Generally speaking, COST1266 is used to seal the joints or the cracks by indirect heating with heat transter oil.

Operation steps: Use the suitable tools to clean the joints or the cracks, remove any dust, oil, grease, print and other contaminants, and keep the cracks or the joints clean and dry.

Hot melt the sealant, the heating temperature of the product is about 180°C-200°C.

Usually, we hot melt the sealant by indirect heating with heat transter oil, instead of directly heating and suddenly heating. Before heating, put it into heating tank (drum) first, step heat up, the heating time is decided by entirely melting of the sealant

For better appearance, cover the outside of the joint areas with Ninon film or paper, lest cause contamination when sealing.

Let it cool down before pouring and sealing the joint. The best pouring temperature is

about 60°C-180°C.

Remove the Ninon film after finishing, keep the surface neat.

We suggest using COST style heating equipment. This equipment has good quality and can be operated easily. It helps improving the construction quality, and developing good work environment. Ending the pouring work, traffic can be opened in time immediately.

Packaging & Shipping

Packaging

shape for the black blocks (flake type), adopts non-stick paper when packing, 15 kg/carton, 20 'container can be hold 1267 cases, net weight 19005 kg.

Shelf life

The best storage temperature of COST - 1266 is 25°C, its storage life for 2 years. Warehouse should be ground clean, cool and ventilated, the goods must be far away from the fire source of heat. If storage temperature is too high, there may be a degree of the packaging carton deformation, but it will not affect the normal use. The goods must be packed neatly, generally the carton placed the height is limited to 4 layers, light light discharge, to avoid damage, dust and Affect the use effect.

Precautions

It is forbidden to direct heat to melt sealing paste; suggestions to indirect heating through heat conduction oil or steam.

Send your message to us

China concrete expansion joint material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords