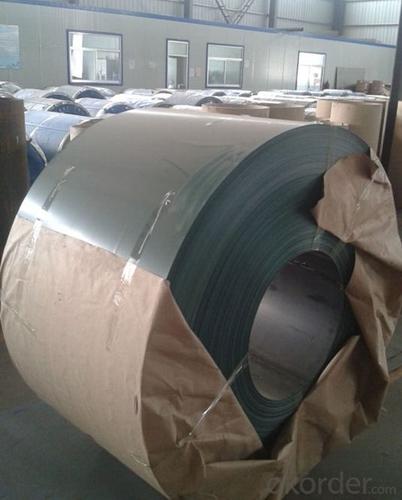

CHEAP PRICES!! First Prime ppgi,ppgi steel coil,ppgi coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CHEAP PRICES!! First Prime ppgi,ppgi steel coil,ppgi coil

Production

Thickness | 0.14mm-2.0mm |

Thickness tolerance | +/- 0.02mm |

Width | 600mm-1250mm |

Color | Grey white, sea blue, red or any RAL standard |

Standard | ASTM, AISI, DIN, GB,JIS |

Material | SGCC,SGCD,SECC,SECD,DX51D+Z, S350GD, S450GD, S550GD |

Technique | Cold rolled, hot-dipped galvanizing, color coated, galvanized, Galvalume |

Surface Structure | Galvanized, Galvalume, zero spangle, regular spangle or normal spangle |

Surface treatment | Chromate and oiled, chromate and non-oiled |

Min order | 25 tons |

Applications:

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorframe, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

Service

1.MOQ:25 ton.

2.Delivery time;15-30days

3.Payment:30% deposite, 70% in L/C before delivery.

4.We can guarantee 100% inspeciton before the shipment

- Q: I heard that titanium isn't the most hypoallergenic metal because it is treated and the chemicals can cause an allergic reaction. I also heard that surgical steel is the best because it is what is used in surgery and in hip replacement implants etc. Is this correct?I've always heard that titanium is best, but now I'm curious because surgical steel is much cheaper than titanium which can be expensive.Thanks

- Implant grade titanium is much better than surgical steel. The nickel content in it (which is what alot of people are allergic to) is virtually non-existant. Though most people with a nickel allergy are fine with surgical steel too, its too small for most people to react to. But the odd few people do. Its the same with everything. Good surgical steel is probably better than cheap titanium. But implant grade ti will beat it hands down. And ti is alot stronger, and is also used in surgical impants and as replacement bits too. But a big lump of titanium hip is going to be expensive. If you're not allergic to steel, theres little reason for the extra cost, especially if it's likely to outlive you. Niobium has no nickel in at all. But that really is expensive, and I've never seen any threaded. Any particular reason why you ask? ----- Piercing-wise titanium will be better than steel. Unless they carry some not so great ti. You should be fine with steel though.

- Q: What are the different methods of embossing steel coils?

- There are several different methods of embossing steel coils, each with its unique characteristics and applications. Some of the most common methods include: 1. Hot embossing: This method involves heating the steel coil to a high temperature and then pressing it between two engraved rollers. The heat softens the steel, making it easier to imprint the desired pattern onto the surface. Hot embossing is often used to create intricate designs or textures on steel coils. 2. Cold embossing: In contrast to hot embossing, cold embossing does not involve heating the steel coil. Instead, it uses pressure and specially designed dies or stamps to create the desired pattern on the surface. Cold embossing is commonly used for simpler designs or when heat-sensitive materials are involved. 3. Roller embossing: Roller embossing is a method that utilizes a series of rollers with engraved patterns to imprint the design onto the steel coil. The steel coil is passed through the rollers, and the pressure applied causes the pattern to be transferred onto the surface. This method is often used for larger-scale production and can achieve consistent and uniform results. 4. Laser embossing: Laser embossing is a modern method that utilizes laser technology to create patterns on steel coils. The laser beam is directed onto the surface, selectively melting or vaporizing the metal to create the desired design. This method offers high precision and flexibility, making it suitable for intricate and detailed patterns. 5. Press embossing: Press embossing involves the use of a press machine equipped with custom-made dies to imprint the desired pattern onto the steel coil. The coil is placed between the dies, and the press machine applies pressure to transfer the pattern onto the surface. This method is commonly used for large-scale production and can achieve high-speed and high-volume embossing. Overall, the choice of embossing method depends on various factors such as the desired design complexity, production volume, material properties, and cost considerations. Each method has its advantages and limitations, and manufacturers must carefully select the most suitable method for their specific requirements.

- Q: What is the major disadvantage of hardened steel? Do you think this form of iron would be wear resistant and retain a sharpened edge?

- a disadvantage is the fact that the cold forming capability of this steel

- Q: does regular steel rust? or is it all the same.

- Dear, Thank you, am also fine like you then dear yeah is the same.

- Q: Can steel coils be coated with thermally conductive materials?

- Yes, steel coils can be coated with thermally conductive materials. These materials are often applied as a thin layer or coating onto the surface of the steel coils to enhance their thermal conductivity. This coating helps in the efficient transfer of heat through the coils, making them suitable for various applications that require effective heat dissipation or thermal management.

- Q: How are steel coils inspected for coil set using deflection measurement?

- Steel coils are commonly inspected for coil set, a condition where the coil exhibits a curvature along its length, by utilizing deflection measurement techniques. Deflection measurement involves applying a force on the coil and measuring the resulting deviation from its original shape. To inspect for coil set, the steel coil is placed on a testing apparatus that can apply controlled pressure to the coil. This apparatus typically consists of a set of rollers or hydraulic cylinders that can exert force on the coil's surface. The first step in the inspection process is to secure the coil in place, ensuring it is properly aligned and centered on the testing apparatus. Once the coil is in position, the apparatus applies a known force along the length of the coil. This force is typically applied in a consistent and controlled manner to ensure accurate measurements. As the force is applied, the deflection of the coil is measured using sensors or gauges positioned at specific points along the length of the coil. These sensors can detect even small deviations from the original shape of the coil. The deflection measurements are recorded and analyzed to determine the severity of coil set. Typically, a set of predetermined acceptance criteria is used to assess the coil's condition. If the recorded deflection measurements exceed these criteria, it indicates the presence of coil set. The severity of the coil set can be determined by comparing the actual deflection measurements with the acceptable range specified by the criteria. Deflection measurement is an effective method for inspecting steel coils for coil set as it provides quantitative data on the deviation from the original shape. This information allows manufacturers to identify and address any coil set issues, ensuring the quality of the steel coils before further processing or shipment to customers.

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers ensure that their products meet transportation standards and regulations for international shipping. This involves following specific packaging requirements, using appropriate containers, and securing the coils to prevent damage during transit. In order to meet international shipping requirements, manufacturers must also comply with customs regulations and documentation. They need to prepare accurate and complete paperwork, such as commercial invoices, packing lists, and bills of lading, to ensure smooth customs clearance procedures. Furthermore, steel coil manufacturers often collaborate with freight forwarders or shipping agents who specialize in international logistics. These professionals have extensive knowledge of shipping regulations, routes, and carriers, and can assist with arranging transportation, negotiating freight rates, and handling necessary paperwork. Manufacturers may also choose to use intermodal transportation, which involves utilizing multiple modes of transportation like trucks, trains, and ships. This allows for more efficient and cost-effective shipping, especially for long-distance or international shipments. Additionally, steel coil manufacturers may consider obtaining insurance coverage to protect their products during transit. Insurance provides financial compensation in case of any damage, loss, or delays during the shipping process. Overall, steel coil manufacturers handle international shipping requirements through careful planning, adherence to regulations, collaboration with logistics experts, and consideration of various transportation options. This ensures that their products reach international destinations safely, on time, and in compliance with all relevant regulations.

- Q: Just two sentences on a detailed description on what the steel industry is

- The steel industry is an industry that produces steel. It is one of the largest industries in the world, with China as the leading steel producer

- Q: How are steel coils weighed?

- Steel coils are typically weighed using industrial weighing scales or load cells. The coils are lifted by cranes or forklifts and placed on the scales or load cells to determine their weight.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- The terms mild steel and carbon steel are general terms and do not refer to a specific grade of steel. If your client asked for A106B then that is what you need to ask your vendor to quote you. If MS1 references A106B then again, that is what you get prices for.

Send your message to us

CHEAP PRICES!! First Prime ppgi,ppgi steel coil,ppgi coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords