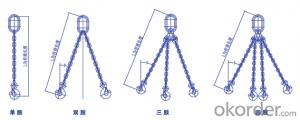

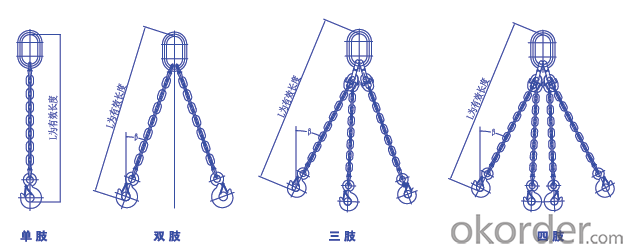

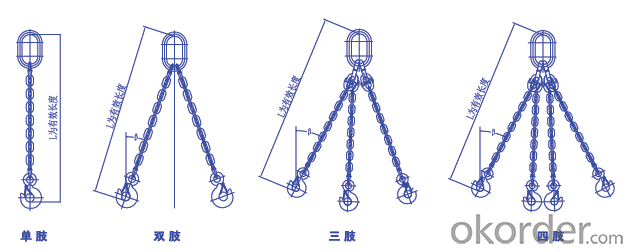

chain sling,Safety factor:4:1,single leg、two legs etc

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chain

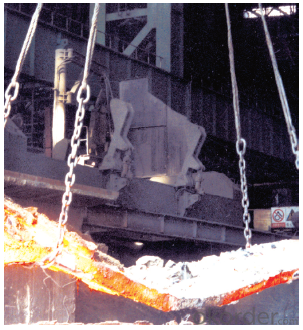

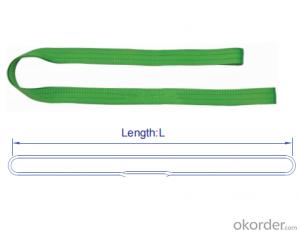

Product Range:Chain sling factory mainly produce high-tensile lifting chain, high-tensile chain sling, round link chain and steel compact chain for scraper conveyor and auxiliary part for mine chain.

Equipment:Chain factory has chain making machine, flash butt welder, stretcher from WaFiOs (german) and sPEcTROMaXx brand metallurgical analysis spectrograph.With the expansion of the market share in recent years, the factory has built 17 chain production lines, 3 chain sling assembly lines and 2 ring welding lines.

Scientific achievements:Mining chain obtained Ma certificate. Lifting chain obtained cE certificate and participated in the compose of GB/T24816 “Short link chain and hoists lifting chain with grade eight ordinary precision chain”. The chain adopts high-quality special steel material from the domestic and foreign market and produced in accordance with the standard of En818-2, gB/ T24816-2009, GB/T12718-2009, Q/JL018-2012.Production range is Φ6-Φ48mm.。

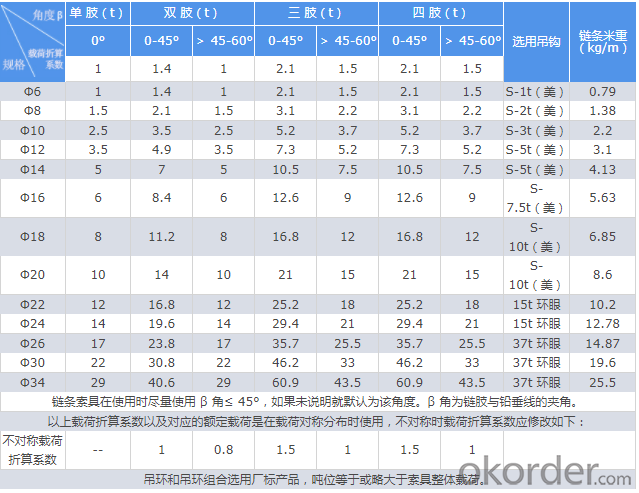

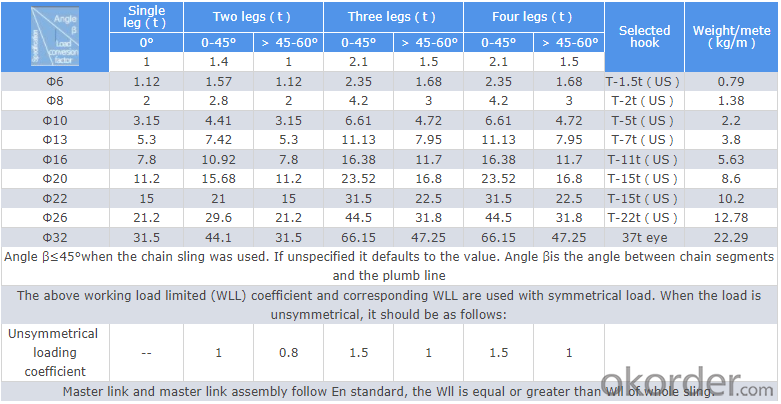

Angle β≤45°when the chain sling was used. If unspecified it defaults to the value. Angle βis the angle between chain segments and the plumb line

- Q: What is the name of the wire above the train?

- The contact wire is mostly made of steel aluminum core, that is, the outside is made of steel, and the main part is the friction part of the pantograph. To ensure the conductivity and wear resistance, the aluminum core is mainly to ensure the conductivity. Copper and aluminum composite wires have also been used as contact wires.

- Q: Why do not different kinds or different sizes of slings and slings are used together?

- Choose proper slings and slings according to the specific conditions of the heavy loads; no heavy weights are allowed to be attached directly with the hooks, and no different kinds are allowed

- Q: What does the inspection of rigging involve?

- Phosphating coating of steel wire rope (Chinese patent), wire by Mn and Zn Mn phosphating treatment of steel wire, wear resistance and corrosion resistance of fully, are not easy to wear and corrosion fatigue life of the phosphating coating steel wire rope is the same structure of plain steel wire rope 3 times (laboratory comparable conditions), exceeding imports of steel wire rope, phosphating coating steel wire rope are fully replace all kinds of plain steel wire rope, also be replaced after plating the first pull layer thin zinc galvanized steel wire rope used (through salt spray test the corrosion resistance test), long service life, use lower cost, better quality stability and reliability.

- Q: What are the selection principles for lifting cranes?

- It can guarantee the quality of hoisting project, safety construction and certain economic benefits.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q: Which sling manufacturer is more reliable?

- A variety of commonly used wire rope phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.

- Q: Notice of tower crane?

- Tower cranes shall not operate near overhead transmission lines. If they are limited to field conditions, they must take safety measures when operating alongside the line. The safe distance between tower crane and overhead transmission line shall comply with the regulation.

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

Send your message to us

chain sling,Safety factor:4:1,single leg、two legs etc

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 set

- Supply Capability:

- 0 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches