CGF Series Washing-Filling-Capping 3-in-1 Monobloc CGF18/18/6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Packing is a professional company specializing in R & D, manufacturing, technical service and sales of beer and beverage packing machinery.

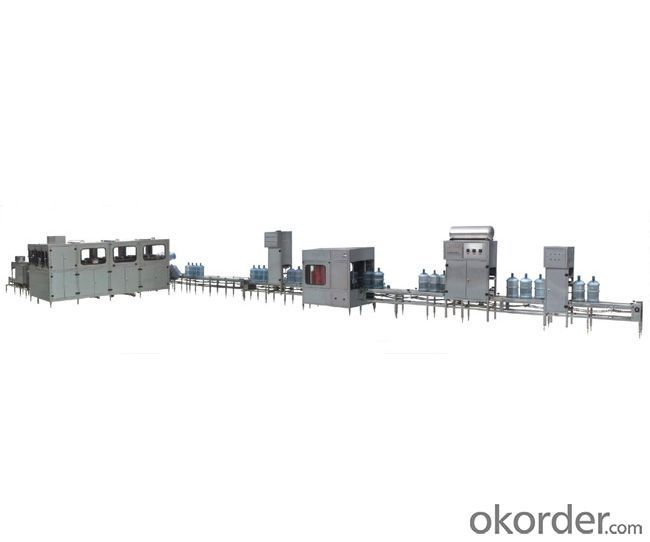

Among the products, RCGF series, CGF series, DCGF series bottle packing and QGF series barrel packing beverage production lines and QHS series beverage mixer are all designed and made on the base of importing the advanced technology from German, Italy and Japan and its technology keeps the same level as international.

Also the company provides technical consultation, factory planning, installing and adjusting technological train and other services.

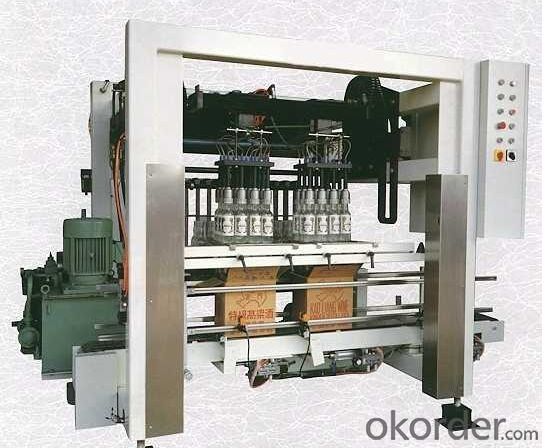

CGF series washing-filling-capping 3-in-1 monobloc:

Usage:

The series equipment is used in filling pure water, mineral water and other drink which does not contain any gas in PET bottles. On one machine, it can carry out washing, filling, capping. The machine adopts filling in normal temperature and normal pressure. The special filling valve makes the filling speed fast and the filling liquid level control correct. The machine adopts frequency control and PLC control. The operation and maintenance are convenient. It is suitable for thinner PET bottles.

Main Technical Parameters:

Model: | CGF16/12/6 | CGF18/18/6 | CGF24/24/8 | CGF32/32/12 | CGF40/40/12 | CGF48/48/12 |

Production Capacity:500ml(B/h) | 4000 | 6000 | 10000 | 14000 | 17000 | 20000 |

Suitable Bottle Standard:(mm) | 150-300 | 150-340 | 150-340 | 150-340 | 150-340 | 150-340 |

Suitable Cap Standard:(mm) | φ50-φ110 | |||||

Filling Pressure:(Mpa) | 0.2-0.3 | |||||

Filling Model: | Gravity type | |||||

Installed Capacity:(kw) | 3.13 | 3.84 | 3.84 | 5.6 | 6.3 | 7.3 |

Filling Temperature: | Room Temperature | Room Temperature | Room Temperature | Room Temperature | Room Temperature | Room Temperature |

Overall SizeL×W×H(mm) | 2400×1670 | 2470×1970 | 2865×2170 | 3700×2570 | 3800×2950 | 4500×3400 |

Total Weight:(kg) | 2500 | 3000 | 4000 | 5000 | 6000 | 7000 |

FAQ CGF series washing-filling-capping 3-in-1 monobloc

1.How about the shipment?

The delivery time is 20 days.

2. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: The role of packaging equipment in packaging equipment

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging equipment is playing a more and more important role in the field of packaging. The main functions of packaging equipment are as follows:

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

Send your message to us

CGF Series Washing-Filling-Capping 3-in-1 Monobloc CGF18/18/6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords