Ceramic Fiber Board - Ceramic Fibre Sheet Paper Al Content (32-55%)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fibre Sheet Paper Al Content (%): 32-55

Structure of Ceramic Fibre Paper Sheet Description

Ceramic fibre is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic fibre paper sheet has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of ceramic fibre paper sheet also has difference,and they are suitable for different workong temperatures.

Ceramic fibre can be used after optional cutting .When ceramic fibre paper sheet storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

We are the main supplier for

Allied mineral products, inc

Refractories incorporated

Srs sorg refractory systems gmbh,

Sunward refractories co., ltd

Lilama69-1 joint stock company etc.

Main Features of the Ceramic Fibre Paper Sheet

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fibre Paper Sheet

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

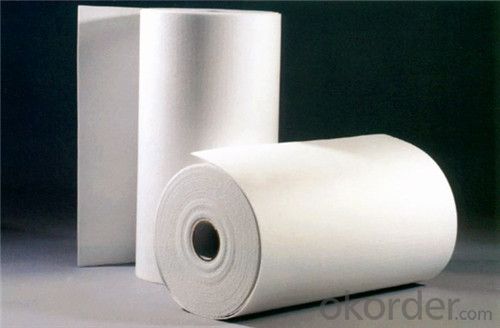

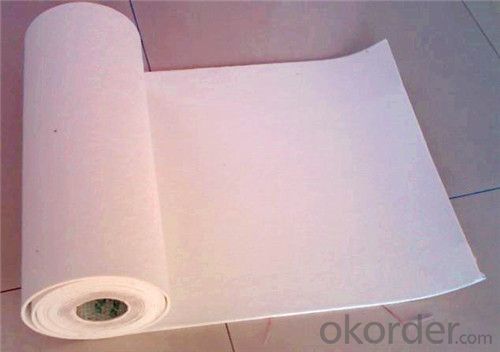

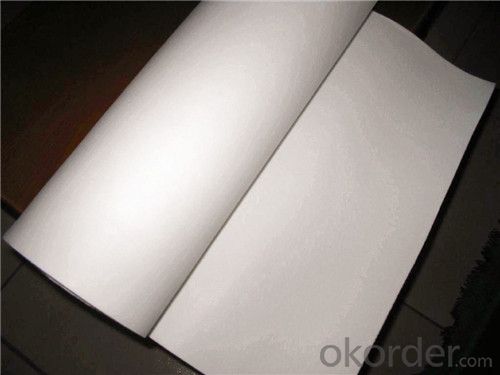

Ceramic Fibre Paper Sheet Images

◆Breif Images

◆Packaging

◆Product Process

Ceramic Fibre Paper Sheet Specification

Type | Ordinary | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

Density (kg/m3) | 96 | 96 | 96 | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

Why us

Professional ceramic fiber manufacturer. We have being specialized in producing refractory ceramic fiber for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

FAQ of Ceramic Fibre Paper Sheet

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us,we will provide our best products and services for you!!

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- The biggest difference between the two is that:1, the coefficient of thermal conductivity is different, the nano ceramic plate is about three times of the ordinary ceramic fiber board2, temperature class is not the same, nano ceramic board maximum temperature of 1050 degrees, ceramic fiber board should be 1400 degrees temperature.3, the range of applications is different. Nano ceramic plate is mainly used in high, fine and sharp technical fields, and has strict requirements on thermal conductivity. Ceramic fiber boards are widely used and can be used wherever there is flame or temperature.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

Ceramic Fiber Board - Ceramic Fibre Sheet Paper Al Content (32-55%)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords