Ceramic Fiber Textiles with Excellent Tensile Strength 2024

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New 2015 Ceramic Fiber Textile with Excellent Tensile Strength

Product Description:

Product Applications:

• Industrial furnace, heating devices, high temperature pipe wall linings;

• High temperature boilers, steam turbine and Nuclear power thermal insulation;

• Chemical industrial high-temperature reaction equipment and heating equipment wall linings;

• High building fireproof and thermal insulation;

• Furnace door and roof thermal insulation;

• High temperature filter materials

Product Specifications:

Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Ceramic Fiber |

SiO₂ Content (%): | 55Max | Al₂O₃ Content (%): | 35Min | MgO Content (%): | 0 |

CaO Content (%): | 0 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 |

SiC Content (%): | 0 | Model Number: | As per request | Brand Name: | |

Color: | white | Thickness: | ~30mm | Characteristics: | Lightweight |

Product Packaging:

Packaging Detail: | One roll in a box (25kg) |

Delivery Detail: | ~25 days after receiving deposit |

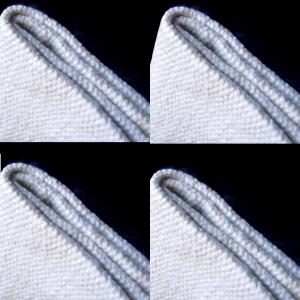

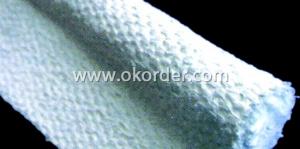

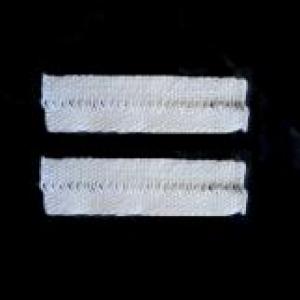

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

Q6: What`s the lead time for my order?

A6: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q7: Can you offer Door-to-Door delivery?

A7: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q8: What is the minimum quantity?

A8: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: What is the function of (ceramic) ceramic powder?

- According to different porcelain stent materials are divided into: metal porcelain powder, pure titanium porcelain powder, casting porcelain powder, two alumina porcelain powder, zirconia porcelain powder, etc.. According to the temperature is divided into: high temperature porcelain powder, medium temperature porcelain powder, low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q: What are the uses of ceramic fiber blankets?

- Ceramic fiber blanket is mainly used for high temperature, tough, self bearing high strength of the place, but also used for high airflow speed, mechanical destruction of large places. Ceramic fiber blanket can be used in these occasions.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- Ceramic fiber cloth, stainless steel wire, enhanced use temperature of 1050 degrees, glass fiber reinforced use temperature of 650 degrees.

- Q: What are the differences between digital textile printing ink and printing ink?

- 1. heat transfer ink:Transfer printing for polyester, nylon and spandex fabrics;2. active ink:Suitable for direct spray onto pure cotton, silk, nylon and other fabrics;

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

Ceramic Fiber Textiles with Excellent Tensile Strength 2024

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords