Carbon Steel Sheet Plate High Quality A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of steel plate:

Our products into high-strength low-alloy steel plate, carbon structural steel plate, alloy structural steel plate, boiler and pressure vessel steel plate, bridge steel plate, structural steel plate, shipbuilding steel plate and marine oil platform steel plate, pipe steel plate, high strength and high toughness steel plate, mold plate, corrosion-resistant plate, Wear-resistand steel plate, composite plate with 12 major series.

2.Size range: Steel Plate width 300-5000mm, thickness 5-600mm, length 1000-18000mm.

Usage: (1).used for metallurgical, mechanical, electrical construction field

(2).used for ships, military (armored) Construction

(3).used for outside engineering, machine tool base, automobile rear of products

3.Standard: According to user requirements, can be delivered the following criteria: National standards, the metallurgical industry, the American ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board.

4.Inspection Standard: In accordance with China (JB4730, GB/T2970), United States (A435, A577, A588), Japan (JISG0801, JISG0901), Germany (SEL072), British (BS5996), France (NFS04-305) and other domestic and international testing standard production test.

5.Data of steel sheet:

TYPE | STEEL sheet |

OUTER DIAMETER | 1000 1250 1500 1800MM |

WALL THICKNESS | 0.3-2.0MM |

THICKNESS TOLORANCE | +/- 002MM |

ZINC COATING | 60G-270G |

STANDARD | iso1461 |

MATERIAL | SPCC |

PACKING | WATERPROOF CLOTH FRISTLY, AND SURFACE TO BE VANISHED AND BE PACKED IN BUNDLES, WRAPPED WITH STEEL STRIP IN MINIMUM IN 5 POINTS, |

SURFACE TREATMENT | BRIGHT FINISHED, SLIT EDGE, OILED |

DELIVERY TIME | ACCORDING TO THE QUANTITY, LESS THAN 20 DAYS |

MOQ | 25TONS |

PRODUCTIVITY | 6000 TONS PER MONTH |

REMARK | ANTI CORRSION AND HIGH TEMPERATURE RESISTANG WITH BLACK PAINTING ALL THE PRODUCTION PROCESS ARE MADE UNDER THE ISO 9001-2000 STRICTLY |

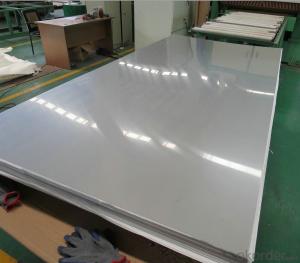

6.Image of steel sheet:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can steel sheets be used for signage or displays?

- Yes, steel sheets can be used for signage or displays. They are durable, versatile, and can be easily shaped and customized to create various signage or display options. Additionally, steel sheets can withstand harsh weather conditions, making them suitable for both indoor and outdoor use.

- Q: What is the thickness of the paint board?

- Paint plate generally in accordance with the "block" as the unit sales, not only as a wall decoration, doors, tables and chairs can do the shelves, cabinets bearing surface, the thickness of 1-2 cm in length, 50 - 120, 30 cm wide case is 55*30*1.5cm

- Q: Are steel sheets fire resistant?

- Yes, steel sheets are fire resistant.

- Q: What are the reasons for the steel mesh on both sides of the back pouring belt?

- Increase overall stability. To prevent cracks due to settlement, uneven cement shrinkage, etc., but also to increase the overall firmness. Generally speaking, the stability of the post casting belt is increased.

- Q: Can the steel sheets be easily drilled for fastening purposes?

- Drilling steel sheets for fastening purposes? Absolutely possible! Steel is renowned for its strength and durability, yet it remains relatively easy to work with when it comes to drilling. By employing the correct tools and techniques, you can effortlessly create holes in steel sheets to attach brackets, screws, or nails. Nevertheless, it's crucial to employ drill bits specifically designed for metal drilling. Moreover, during the drilling process, it might be necessary to utilize lubricants or cooling agents to prevent overheating and potential damage to the drill bit. Although drilling through steel sheets demands additional effort and careful handling, rest assured, it can be accomplished successfully for fastening purposes.

- Q: What is the maximum temperature steel sheets can withstand?

- The maximum temperature steel sheets can withstand varies depending on the grade and composition of the steel. However, most common grades of steel can withstand temperatures up to around 600-650 degrees Celsius (1112-1202 degrees Fahrenheit) without significant loss of strength.

- Q: What is the difference between a standard and high-strength steel sheet?

- The difference between a standard and high-strength steel sheet lies in their respective mechanical properties and performance characteristics. Standard steel sheets are often made from low to medium carbon steel, typically with a yield strength of around 250 MPa (megapascals). These sheets are commonly used in applications that do not require extreme strength or resistance to deformation. On the other hand, high-strength steel sheets are manufactured with a higher carbon content and alloying elements such as manganese, chromium, or nickel. This composition enables them to have significantly higher yield strengths, ranging from 350 to 1,000 MPa or even more. As a result, high-strength steel sheets offer enhanced resistance to deformation, higher tensile strength, and improved durability. Due to their superior mechanical properties, high-strength steel sheets are often selected for applications that demand increased strength-to-weight ratios, such as automotive components, structural parts, and heavy machinery. These sheets can withstand higher loads, endure extreme conditions, and provide better protection in case of impact or sudden forces. While standard steel sheets are more readily available and less expensive, high-strength steel sheets are preferred in situations where superior strength and performance are necessary. However, it is important to note that high-strength steel sheets may be more challenging to form, weld, or machine due to their increased hardness. Therefore, careful consideration of the specific application requirements is crucial when choosing between standard and high-strength steel sheets.

- Q: What is the weight of a steel sheet?

- The weight of a steel sheet can vary depending on its dimensions and thickness.

- Q: Are steel sheets suitable for interior ceiling panels?

- Yes, steel sheets are suitable for interior ceiling panels. They are durable, fire-resistant, and can provide a modern and sleek appearance to any space. Additionally, steel sheets are easy to clean and maintain, making them a practical choice for interior ceiling applications.

- Q: What are the different coating options for steel sheets (powder coating, paint, etc.)?

- There are several different coating options available for steel sheets, each offering unique benefits and characteristics. Some of the most common coating options include: 1. Powder coating: Powder coating involves applying a dry powder coating material onto the steel sheet. This coating is then cured under heat to form a protective layer. Powder coating provides excellent durability, corrosion resistance, and aesthetic appeal. It is also environmentally friendly, as it does not contain solvents or VOCs. 2. Paint: Paint is one of the most traditional coating options for steel sheets. It involves applying liquid paint onto the surface, which then dries and forms a protective layer. Paint coatings offer a wide range of colors and finishes, making them suitable for various applications. However, they may require periodic maintenance and can be susceptible to chipping and peeling. 3. Galvanizing: Galvanizing is a popular coating method for steel sheets, especially in industries where corrosion resistance is crucial. It involves applying a layer of zinc onto the steel surface through a hot-dip process. This creates a protective barrier that prevents corrosion and rusting. Galvanized coatings are highly durable and long-lasting. 4. Epoxy coatings: Epoxy coatings are known for their excellent chemical resistance and adhesion properties. They provide a tough and durable finish that protects steel sheets from corrosion, chemicals, and abrasion. Epoxy coatings are commonly used in industrial settings where harsh conditions are prevalent. 5. Chromate conversion coatings: Chromate conversion coatings, also known as chemical conversion coatings, are applied to steel sheets to enhance their corrosion resistance and improve paint adhesion. These coatings are typically thin and translucent, providing a clear or slightly yellowish appearance. Chromate conversion coatings are commonly used as a pre-treatment before painting or powder coating. 6. Ceramic coatings: Ceramic coatings offer exceptional heat resistance and durability. They are often utilized in high-temperature applications, such as exhaust systems or industrial ovens. Ceramic coatings can withstand extreme temperatures, corrosion, and abrasion, making them ideal for demanding environments. These are just a few of the coating options available for steel sheets. The choice of coating will depend on factors such as the intended application, desired appearance, environmental conditions, and budget. Consulting with a coating specialist or manufacturer can help determine the most suitable coating option for specific requirements.

Send your message to us

Carbon Steel Sheet Plate High Quality A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords