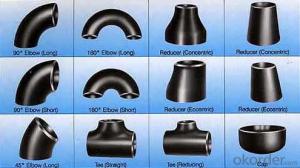

Carbon steel pipe fittings ELBOW FLANGE TEE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials. This work involves selecting and preparing pipe or tubing, joining it together by various means, and the location and repair of leaks.

Pipe fitting work is done in many different settings: HVAC, manufacturing, hydraulics, refineries, nuclear-poweredSupercarriers and Fast Attack Submarinescomputer chip fab plants, power plant construction and other steam systems. Pipe fitters (sometimes called simply "fitters") are represented in the USA and Canada by the United Association of Journeymen and Apprentices of the Plumbing and Pipe Fitting Industry of the United States and Canada.

Fitters work with a variety of pipe and tubing materials including several types of steel, copper, iron, aluminium, and plastic. Pipe fitting is not plumbing; the two are related but separate trades. Pipe fitters who specialize in fire prevention are called Sprinklerfitters, another related, but separate trade.

Materials, techniques, and usages vary from country to country as different nations have different standards to install pipe.

Elbow are an English alternative rock band consisting of Guy Garvey (vocals, guitar), Richard Jupp (drums, percussion), Craig Potter (keyboards, piano), Mark Potter (guitar, backing vocals), and Pete Turner (bass guitar, backing vocals). They have played together since 1990, adopting the Elbow band name in 1997, and have released six studio albums: Asleep in the Back (2001), Cast of Thousands (2003), Leaders of the Free World (2005), The Seldom Seen Kid (2008), Build a Rocket Boys! (2011), and The Take Off and Landing of Everything (2014). All of their studio albums, as well as B-sides compilation Dead in the Boot (2012), have placed in the top 15 of the British album chart and seven of their singles have placed in the top 40 of the British singles chart.

In 2008 Elbow won the Mercury Music Prize for their album The Seldom Seen Kid, and in 2009 they won the Brit Award for Best British Group In 2012 they released "First Steps", the BBC theme for the 2012 London Olympics

Specifications

Standard: ASTM A234 WPB, JIS, DIN, EN, GOST

Use for Oil, Gas, Subwatering act.

45/90/180 degree, LR/SR Elbow

ASTM A234 WPB ELBOW :

| ||||||||

| we are manufacturer for carbon steel pipe and fittings,like 45deg,90deg,180deg,L/R OR S/R,bend , | ||||||||

| equal or reducing tee, CON reducer, ECC reducer, pipe cap,flange. | ||||||||

| CON AND ECC REDUCER: CARBON STEEL,STAINLESS,STELL,ALLOY STEEL | ||||||||

| NOMINAL DIAMETER | BIG OD1 | SMALL OD2 | HEIGHT(MM) | |||||

| MM | SERIES A | SERIES B | SERIES A | SERIES B | 51-711 | |||

| 25*15--1500*1400 | 33.7-1524 | 32-1520 | 21.3-1420 | 18-1420 | ||||

| MATERIAL: A234WPB,A283,A105,A53,A106,API5L | ||||||||

| STANDARD: ASTM/ANSI,DIN,ISO,GB,JIS,BS ,GOST | ||||||||

| OTHERS: | ||||||||

| 1. Special design available according to requirement | ||||||||

| 2. All the production process are made under the ISO 9001:2000 strictly. | ||||||||

- Q: What are the different types of steel sheets and their uses in the packaging industry?

- There are various types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is commonly used for food packaging due to its corrosion resistance and ability to maintain product freshness. Galvanized steel sheets are used for heavy-duty packaging, such as shipping containers, as they provide strength and durability. Stainless steel sheets are often used in the pharmaceutical industry for packaging sensitive or corrosive substances, thanks to their resistance to chemical reactions and contamination.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q: What are the applications of alloy steel in the aerospace industry?

- Alloy steel is extensively used in the aerospace industry for various applications due to its superior strength, durability, and resistance to corrosion. It is commonly employed in the manufacturing of aircraft components such as landing gears, engine parts, turbine blades, and structural elements. The high strength-to-weight ratio of alloy steel enables the construction of lighter yet stronger aircraft, resulting in improved fuel efficiency, increased payload capacity, and enhanced overall performance. Additionally, alloy steel's resistance to extreme temperatures and pressure fluctuations makes it an ideal choice for aerospace applications, ensuring the reliability and safety of aircraft in demanding operational conditions.

- Q: What are the factors to consider when choosing the right steel product for a specific application?

- When choosing the right steel product for a specific application, several factors need to be considered. These factors include the required strength and durability, corrosion resistance, cost-effectiveness, ease of fabrication and installation, availability, and environmental impact. Additionally, factors such as weight, aesthetics, and compatibility with other materials or systems may also play a role in the decision-making process. Overall, understanding the specific requirements of the application and evaluating the various characteristics of different steel products is crucial in making an informed choice.

- Q: What are the different types of steel wire mesh and grids available?

- There are several types of steel wire mesh and grids available, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Welded wire mesh is made by welding the intersections of wires together, providing a strong and rigid mesh. Woven wire mesh is created by weaving wires together in a specific pattern, offering flexibility and versatility. Expanded metal mesh is produced by cutting and stretching a sheet of metal, resulting in a mesh with diamond-shaped openings. Perforated metal mesh is made by punching holes in a metal sheet, allowing for various hole sizes and patterns. Each type of steel wire mesh and grid has its own unique characteristics and applications.

- Q: What are the advantages of using steel in the construction of airports?

- There are several advantages of using steel in the construction of airports. Firstly, steel is a highly durable material, which makes it capable of withstanding heavy loads and extreme weather conditions, ensuring the structural integrity of the airport buildings. Secondly, steel structures can be prefabricated off-site, allowing for faster construction times and reduced labor costs. Additionally, steel is a recyclable material, making it a sustainable choice for airport construction as it helps reduce environmental impact. Lastly, steel offers design flexibility, enabling architects to create unique and modern airport structures that are visually appealing.

- Q: How are steel bars used in the reinforcement of dams and reservoirs?

- Steel bars, also known as reinforcement bars or rebars, are commonly used in the construction and reinforcement of dams and reservoirs. They are strategically placed within the concrete structures to enhance their strength and durability. These steel bars act as tension resistance, reinforcing the concrete and helping to withstand the forces exerted on the dams and reservoirs, such as water pressure and seismic activity. Steel bars are vital components in ensuring the stability and longevity of these structures, ultimately preventing any potential failure or damage.

- Q: How is steel used in the production of oil and gas pipelines?

- Steel is commonly used in the production of oil and gas pipelines due to its strength, durability, and resistance to corrosion. It is used to manufacture the pipes that transport oil and gas over long distances, ensuring a reliable and safe transfer of these resources. Steel pipes are able to withstand high pressure and extreme temperatures, making them well-suited for the demanding conditions of the oil and gas industry. Furthermore, steel can be easily welded, allowing for the construction of seamless and leak-proof pipelines, which are crucial for preventing any leakage or environmental hazards.

- Q: What are the different types of steel products used in the manufacturing of tools and machinery?

- There are several types of steel products used in the manufacturing of tools and machinery. Some common examples include carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is widely used due to its strength and affordability. Alloy steel contains additional elements such as chromium, nickel, and molybdenum to enhance specific properties like hardness and corrosion resistance. Stainless steel is favored for its resistance to rust and staining, making it suitable for tools and machinery used in moisture-prone environments. Tool steel is specifically designed for tool-making, offering high hardness, wear resistance, and toughness.

- Q: How is steel wire rope lubricated for optimal performance?

- Steel wire rope is lubricated for optimal performance by applying a suitable lubricant to the individual wires and strands of the rope. This lubricant helps to reduce friction, prevent corrosion, and extend the lifespan of the rope. Various methods such as immersion, spray, or brushing can be used to ensure thorough lubrication of the wire rope. Regular and proper lubrication is essential to maintain the flexibility, strength, and overall performance of the steel wire rope.

Send your message to us

Carbon steel pipe fittings ELBOW FLANGE TEE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords