Carbon Raiser Caclined Anthracite Coal CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

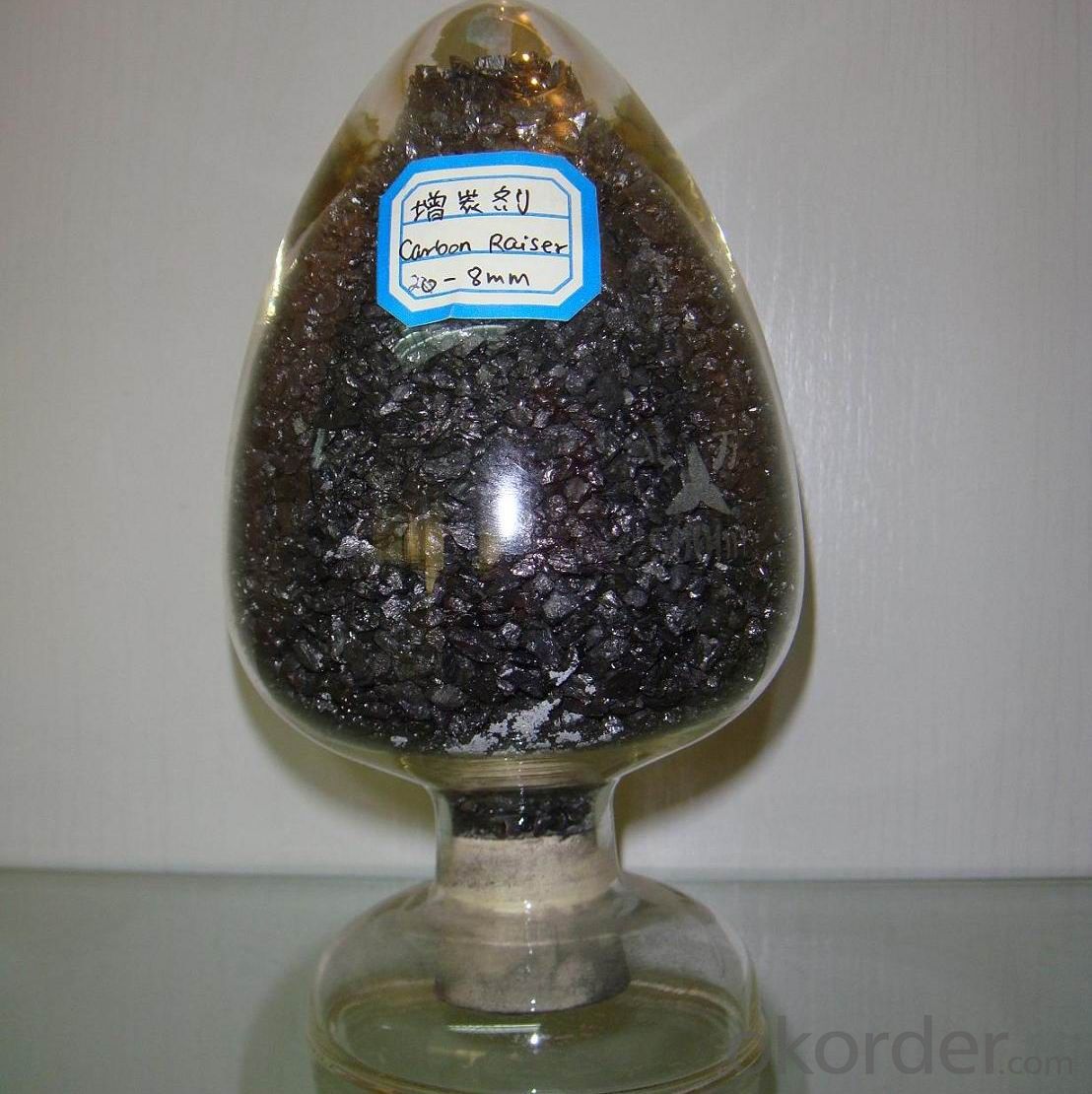

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Raiser Caclined Anthracite Coal CA

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Raiser Caclined Anthracite Coal CA

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Raiser Caclined Anthracite Coal CA

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Raiser Caclined Anthracite Coal CA

FAQ:

Carbon Raiser Caclined Anthracite Coal CA

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Raiser Caclined Anthracite Coal CA

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How does carbon affect the formation of acidification in lakes?

- Lakes undergo acidification due to the significant role played by carbon dioxide (CO2). Human activities, such as burning fossil fuels, release carbon dioxide into the atmosphere. This carbon dioxide can then be absorbed by lakes, resulting in the formation of carbonic acid (H2CO3), a weak acid. When carbonic acid interacts with water, it dissociates into hydrogen ions (H+) and bicarbonate ions (HCO3-). The increase in hydrogen ions causes a decrease in pH levels, making the water more acidic. This process is commonly referred to as acidification. The acidification of lakes can have detrimental effects on aquatic ecosystems. It negatively impacts the physiology and behavior of various species, including fish, amphibians, and invertebrates. Furthermore, the eggs and larvae of these organisms can be damaged by acidic waters, hindering their growth and survival. Acidification also has the potential to disrupt the composition and abundance of phytoplankton, which are vital for maintaining the overall health of the ecosystem. Additionally, high levels of acidity can result in the leaching of toxic metals, such as aluminum, from the surrounding soil and rocks. These toxic metals then dissolve in the water, posing an additional threat to aquatic organisms. Acidification can also disrupt the nutrient cycles in lakes, ultimately affecting the availability of essential nutrients for plants and animals. To summarize, the presence of carbon dioxide in the atmosphere contributes to the acidification of lakes when it is absorbed by water. This acidification has a range of negative impacts on the aquatic ecosystem, including altered physiology, impaired reproduction, and disrupted nutrient cycles. It is imperative to reduce carbon emissions and mitigate the effects of acidification to safeguard the health and diversity of lake ecosystems.

- Q: What are carbon sinks?

- Carbon sinks are natural or artificial reservoirs that absorb and store carbon dioxide from the atmosphere. They play a crucial role in mitigating climate change by reducing the concentration of greenhouse gases in the atmosphere. Carbon sinks can be found in various forms, including forests, oceans, wetlands, and soil. Forests are the largest and most well-known carbon sinks. Through the process of photosynthesis, trees absorb carbon dioxide and convert it into oxygen, storing the carbon in their trunks, branches, and roots. Oceans are also significant carbon sinks, as they absorb about a quarter of the carbon dioxide emitted by human activities. Algae, phytoplankton, and other marine organisms capture carbon through photosynthesis and convert it into biomass. Wetlands, such as marshes and swamps, are another important carbon sink. These areas store enormous amounts of carbon in their vegetation and soil, preventing it from being released back into the atmosphere. Additionally, soil acts as a carbon sink by absorbing and storing carbon through the decomposition of organic matter and the action of microorganisms. Artificial carbon sinks, like carbon capture and storage (CCS) technologies, are being developed to further combat climate change. CCS involves capturing carbon dioxide emissions from power plants and industrial facilities and storing them underground or repurposing them for other uses. While these technologies are still in the early stages, they have the potential to significantly reduce carbon emissions and help stabilize the climate. Overall, carbon sinks are essential for maintaining the balance of carbon dioxide in the atmosphere and preventing its accumulation, which would contribute to global warming. Preserving and restoring natural carbon sinks, such as forests and wetlands, is crucial for mitigating climate change, while developing and implementing artificial carbon sinks can further aid in reducing greenhouse gas emissions.

- Q: Can carbon be recycled?

- Yes, carbon can be recycled. Carbon recycling refers to the process of capturing and reusing carbon dioxide (CO2) emissions instead of releasing them into the atmosphere. There are several methods of carbon recycling, including: 1. Carbon capture and storage (CCS): This process involves capturing CO2 emissions from power plants or industrial facilities and storing them underground or in deep ocean formations. CCS helps prevent the release of CO2 into the atmosphere, reducing its impact on climate change. 2. Carbon capture and utilization (CCU): CCU involves capturing CO2 emissions and converting them into useful products. For example, CO2 can be converted into fuels, chemicals, or building materials through various chemical and biological processes. 3. Enhanced oil recovery (EOR): This technique involves injecting captured CO2 into oil reservoirs to increase the amount of oil that can be recovered. It not only helps to recycle carbon but also increases oil production. 4. Biological carbon sequestration: This method involves using plants, trees, and other biological organisms to absorb CO2 from the atmosphere through photosynthesis. By promoting reforestation, afforestation, and sustainable land management practices, we can increase carbon sequestration and offset emissions. While carbon recycling technologies are still being developed and improved, they offer promising solutions for reducing greenhouse gas emissions and mitigating climate change. By recycling carbon, we can reduce our reliance on fossil fuels, decrease the release of CO2 into the atmosphere, and work towards a more sustainable and low-carbon future.

- Q: How does carbon impact air quality?

- The release of carbon dioxide (CO2) and other carbon-based pollutants into the atmosphere can significantly affect air quality. When fossil fuels like coal, oil, and natural gas are burned, they emit large amounts of carbon dioxide, a greenhouse gas that contributes to climate change. This increase in carbon dioxide levels in the atmosphere causes the Earth's surface to warm, leading to adverse effects on air quality. Moreover, incomplete combustion of fossil fuels and other organic materials can also release carbon-based pollutants like carbon monoxide (CO) and volatile organic compounds (VOCs). These pollutants have detrimental effects on human health and can contribute to the formation of ground-level ozone, which is a major component of smog. Breathing in ozone can cause respiratory problems, lung damage, and worsen existing respiratory conditions such as asthma. Additionally, burning fossil fuels, biomass, and other organic matter releases carbon particles known as black carbon or soot. These particles directly impact air quality by absorbing sunlight and reducing visibility. When inhaled, they can penetrate deep into the lungs, leading to respiratory issues and potential long-term health problems. To improve air quality and mitigate the negative impacts on human health and the environment, it is crucial to reduce carbon emissions. This can be achieved by transitioning to cleaner and more sustainable energy sources, such as renewable energy. Additionally, implementing stricter regulations and emission standards for industries and vehicles can contribute to reducing carbon pollution and improving overall air quality.

- Q: What is carbon fiber reinforced plastic?

- By combining carbon fibers with a polymer matrix, namely epoxy resin, carbon fiber reinforced plastic (CFRP) is produced. Its exceptional strength-to-weight ratio sets it apart as a lightweight alternative to conventional materials like steel and aluminum. The carbon fibers offer high tensile strength and stiffness, while the polymer matrix evenly distributes the load and ensures durability. The manufacturing process involves layering carbon fiber sheets or fabrics and saturating them with the polymer resin. Subsequently, this combination is cured under high temperature and pressure, resulting in a solid and rigid structure. The resulting material is incredibly strong, yet significantly lighter than materials of comparable strength, such as steel. Thanks to its unique properties, CFRP finds widespread applications in various industries. In aerospace and automotive sectors, it is commonly employed to reduce component weight and enhance fuel efficiency. Moreover, it finds use in sports equipment like bicycles, tennis rackets, and golf clubs, as it enables superior performance and maneuverability. The construction industry also utilizes CFRP, benefiting from its high strength and corrosion resistance for reinforcing structures like bridges and buildings. All in all, carbon fiber reinforced plastic is a versatile and high-performance material that combines the strength of carbon fibers with the flexibility of a polymer matrix. Its lightweight nature and exceptional mechanical properties make it a favored choice in industries where strength, weight reduction, and durability are paramount.

- Q: What are some common compounds of carbon?

- Due to its unique bonding abilities with other carbon atoms and a variety of elements, carbon has the ability to form a wide range of compounds. Carbon dioxide (CO2), methane (CH4), ethanol (C2H5OH), ethene (C2H4), acetic acid (CH3COOH), and glucose (C6H12O6) are some common compounds of carbon. These compounds play crucial roles in various fields such as biology, chemistry, and industry. For instance, carbon dioxide serves as a greenhouse gas, impacting the Earth's climate system significantly. Methane, on the other hand, is a potent greenhouse gas released during natural gas production, contributing to climate change. Ethanol is a widely-used alcohol as a fuel and solvent, while ethene is utilized in plastic production. Acetic acid is a vital component in vinegar, and glucose acts as a primary energy source for living organisms. The vast versatility and importance of carbon are evident through these compounds.

- Q: How accurate is carbon dating?

- Carbon dating, also known as radiocarbon dating, is a widely used scientific method to determine the age of organic materials up to 50,000 years old. It is based on the principle of measuring the ratio of radioactive carbon-14 (C-14) to stable carbon-12 (C-12) in a sample. Carbon dating has proven to be a highly accurate method, with a relatively small margin of error. The accuracy of carbon dating depends on several factors, including the quality and preservation of the sample, the precision of the measurement instruments, and the understanding of the carbon cycle in the past. One of the main limitations of carbon dating is that it can only be used on organic materials that were once alive. This means that it is not applicable for dating inorganic materials such as rocks or minerals. Additionally, carbon dating is most effective for samples younger than 50,000 years old, as the amount of C-14 decreases over time, making it more challenging to measure accurately. To ensure accuracy, scientists often use multiple dating methods or cross-reference their results with other independent dating techniques. This helps to verify the reliability of carbon dating and provide a more comprehensive understanding of the age of the sample. In recent years, advancements in technology and calibration methods have further improved the accuracy of carbon dating. For instance, the use of Accelerator Mass Spectrometry (AMS) allows for smaller sample sizes and greater precision in measurements, reducing the margin of error. Calibration curves based on tree rings, known as dendrochronology, also help refine the accuracy of carbon dating. While carbon dating is a highly reliable method, it is important to acknowledge that no dating technique is perfect. There are inherent limitations and uncertainties associated with all scientific dating methods. However, with proper calibration and careful analysis, carbon dating remains one of the most accurate ways to determine the age of organic materials.

- Q: Now the furnace rock carbon early deleted, more than +10, he wants advanced I can't do ah

- Premium carbon was bought when you bought a holiday suit. Occasionally, the mall also sold. Since the strengthening of the revision has not yet appeared. I'm afraid it's out of print,. Strengthening 11 does not necessarily require that advanced carbon.

- Q: Search for a summary of the importance of carbon in life. If you write well, you can add points,

- People familiar with the organic carbon material more use in daily life and industrial and agricultural production, mainly on gasoline, diesel, kerosene, liquefied gas, natural gas, chemical solvents and fire extinguishing agents such as carbon tetrachloride, carbohydrates (rice, wheat, corn, sorghum, sweet potatoes, potatoes, sugar, fruit, vegetables, paper etc.) chemical fiber, cotton, wood, etc. not all examples.In short, without carbon and its compounds on earth, humans and all living things can not survive and develop, or the earth is a lifeless sphere with only rocks and soil

- Q: There are several allotropes of carbon

- Allotrope of carbon: diamond, graphite, carbon 60 (fullerene), amorphous carbon (charcoal, coke, activated carbon, etc.)

Send your message to us

Carbon Raiser Caclined Anthracite Coal CA

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords