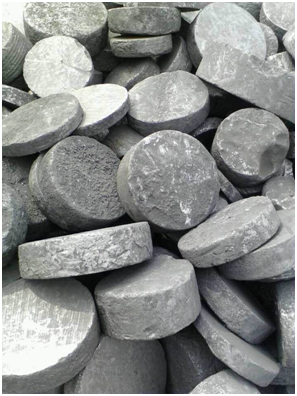

Carbon electrode paste graphite paste with high-purity as carbon additive and carburant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications:

F.C 98%min and 98.5%min, size: 100mm up

- Description & Application

Electrode block processing of carburant in steelmaking and casting, than ordinary recarburizer absorption rate is high, easy to melt, can efficiently improve the quality of products and reduce the cost.

- Technical Specification

F.C (min) |

| 98% |

S (max) |

| 0.05% |

ASH (max) |

| 1.00% |

Vm (max) |

| 1.00% |

H2O (max) |

| 0.50% |

SIZE |

| |

- Q: What are carbon offsets?

- Carbon offsets are a way to compensate for greenhouse gas emissions by supporting projects that reduce or remove carbon dioxide from the atmosphere, such as reforestation or renewable energy initiatives. They essentially enable individuals or organizations to balance out their carbon footprint by investing in activities that counteract their own emissions.

- Q: How does carbon contribute to global warming?

- The greenhouse effect, caused by carbon, contributes to global warming. When carbon dioxide (CO2) and other greenhouse gases are released into the atmosphere, they trap heat from the sun, preventing its escape into space. As a result, the Earth's surface temperature increases and global warming occurs. The primary cause of carbon emissions is the burning of fossil fuels such as coal, oil, and natural gas for energy production, transportation, and industrial processes. These activities release significant amounts of CO2 into the atmosphere, which accumulates over time and intensifies the greenhouse effect. Deforestation and changes in land use also play a role in rising carbon levels. Trees and plants absorb CO2 through photosynthesis, acting as a natural carbon sink. However, when forests are cleared, the stored carbon is released back into the atmosphere. Additionally, the loss of trees reduces the overall capacity for CO2 absorption, aggravating the problem. The consequences of increased carbon emissions are extensive. Rising temperatures lead to the melting of polar ice caps and glaciers, resulting in sea-level rise and posing a threat to coastal communities. Moreover, carbon-driven global warming disrupts weather patterns, giving rise to extreme weather events like hurricanes, droughts, and heatwaves. To mitigate the impact of carbon on global warming, efforts must be made to reduce carbon emissions. This can be accomplished by transitioning to renewable energy sources such as solar and wind power, enhancing energy efficiency, promoting sustainable practices in agriculture and forestry, and implementing policies that encourage carbon capture and storage. Addressing carbon emissions is vital in combating global warming and its associated consequences. By comprehending the role of carbon in the greenhouse effect, we can work towards a sustainable future that minimizes the adverse effects of climate change.

- Q: Where are carbon fiber sheets and carbon fiber sheets used?

- Carbon fiber and carbon fiber cloth, carbon fiber cloth, carbon fiber woven cloth, carbon fiber prepreg, carbon fiber cloth, carbon cloth, carbon fiber fabric, carbon fiber, carbon fiber sheet (prepreg) etc.. Carbon fiber reinforced fabric is one kind of unidirectional carbon fiber reinforced product, usually made of 12K carbon fiber silk fabric. To reinforce the structure of the tensile and shear strength and seismic carbon fiber cloth, the supporting material and impregnated together using a carbon fiber composite material, carbon fiber cloth sheet excellent performance can be enhanced to form a complete system, suitable for processing the building load increasing, the engineering function change, material aging, concrete strength grade is lower than reinforcement design, structure crack treatment, environment protection and repair service component.Carbon fiber board 1) Aerospace: airframe, rudder, rocket engine shell, missile diffuser, solar panel, etc.;2) sports equipment: auto parts, motorcycle parts, fishing rods, baseball bats, skis, boats, badminton rackets and so on;3) industry: engine parts, concrete structures, reinforced materials, fan blades, transmission shaft, and electrical components and so on;4) fire: suitable for army, fire fighting, steel mills and other special high-grade fireproof clothing production.Fire rating: Class A - non flammable, standard GB8624-2006, German standard DIN4102, A1 classCivil buildings, bridges, tunnels, earthquake, reinforced concrete structure, reinforcing material for reinforcement structure, tensile shear and seismic carbon fiber cloth, the use of common materials and supporting adhesive, constitute a complete performance excellence with carbon fiber cloth material reinforcing system. The system is suitable for beams, columns, slabs, tunnels, circles, arcs, etc..

- Q: How much carbon does it take for 4 people to barbecue?!

- Hello The amount of charcoal is according to the number, the number of barbecue barbecue food and other circumstances, the amount of each person is different, generally 6 pounds of charcoal enough for 3-5 to use, recommended to get for a little extra, so is not enough, the charcoal is not expired, can not run out of the next and then, put in the house you can also clean the indoor air.

- Q: What is carbon black filler?

- Carbon black filler is a type of additive that is commonly used in the production of rubber and plastic products. It is a fine, powdery substance that is derived from the incomplete combustion of hydrocarbons, such as oil or natural gas. Carbon black filler is composed primarily of elemental carbon, with small amounts of other elements such as hydrogen, oxygen, and sulfur. The main purpose of using carbon black filler is to improve the physical properties of rubber and plastic materials. It is added to enhance the strength, durability, and wear resistance of the final product. Carbon black filler also helps to increase the stiffness and hardness of the material, making it more suitable for various applications. In addition to its mechanical properties, carbon black filler also provides other benefits. It acts as a reinforcing agent, increasing the tensile strength and tear resistance of rubber compounds. It also enhances the electrical conductivity of the material, making it useful in applications where static electricity needs to be dissipated. Moreover, carbon black filler helps to protect the material from the harmful effects of UV radiation and ozone. It acts as a UV stabilizer and antioxidant, preventing degradation and prolonging the lifespan of the product. Carbon black filler also improves the thermal conductivity of rubber and plastic materials, aiding in heat dissipation. Overall, carbon black filler is a versatile and widely used additive in the manufacturing industry. Its unique properties make it an essential component in the production of a wide range of rubber and plastic products, including tires, conveyor belts, hoses, gaskets, and many more.

- Q: What are the different types of carbon-based pigments?

- Various industries widely use several different types of carbon-based pigments. Some of the most commonly used types are carbon black, graphite, charcoal, and lampblack. Carbon black, renowned for its intense black color, is a highly pure form of carbon produced through the incomplete combustion of hydrocarbon fuels. It finds extensive applications in inks, paints, plastics, and rubber products. Graphite, on the other hand, is an important carbon-based pigment known for its dark gray to black shade. It is a brittle material that can be easily crushed into a fine powder. Graphite is primarily used in pencils due to its ability to leave a smooth and consistent mark on paper. Additionally, it finds utility in lubricants, batteries, and electrical conductors. Charcoal, obtained by burning wood or organic materials without oxygen, is a carbon-based pigment admired for its deep black color. Artists commonly use charcoal as a drawing medium because it can be easily manipulated and smudged on paper, allowing for the creation of various tones and textures. Lampblack, also referred to as carbon black or soot, is a pigment produced by burning organic materials like oil or wood. It possesses a profound black hue and is frequently employed in printing inks, coatings, and dyes. Lampblack is also utilized in diverse industrial applications, including as a coloring agent in plastics and rubber products. These examples represent only a fraction of the diverse carbon-based pigments commonly employed. Each type possesses unique attributes and serves essential purposes in various industries.

- Q: What are the consequences of increased carbon emissions on indigenous communities?

- Indigenous communities are severely affected by the increased carbon emissions, with their traditional lands and natural resources degrading as one of the most immediate consequences. These emissions contribute to global warming, resulting in higher temperatures, altered weather patterns, and more frequent and intense natural disasters like hurricanes, droughts, and wildfires. These events can cause crop destruction, infrastructure damage, and the displacement of indigenous peoples from their ancestral territories. Furthermore, carbon emissions contribute to air pollution, which disproportionately affects indigenous communities living near industrial facilities and exposes them to higher levels of toxic pollutants. This exposure leads to respiratory illnesses, cardiovascular diseases, and other health problems, exacerbating existing health disparities. Climate change-induced loss of biodiversity also has an impact on indigenous communities, as they rely on traditional knowledge and practices for sustainable resource management. Changes in ecosystems disrupt the availability and abundance of food, water, and medicinal plants, undermining indigenous cultures and traditional livelihoods. Moreover, many indigenous communities heavily depend on natural resources such as fishing, hunting, and agriculture for economic development. However, with increased carbon emissions, these resources become scarcer and less reliable, posing economic challenges and creating financial insecurity for indigenous communities. In addition to the environmental and economic consequences, increased carbon emissions also contribute to the loss of cultural heritage and identity. Indigenous communities have a deep connection to their territories and the natural world, which is threatened by the impacts of climate change. This loss of cultural heritage not only negatively affects indigenous communities but also diminishes the diversity of human knowledge and perspectives, which is detrimental to humanity as a whole. In summary, the consequences of increased carbon emissions on indigenous communities are extensive and severe. They not only undermine their traditional lands, resources, and health but also erode their cultural heritage and identity. Recognizing and addressing these impacts is crucial to ensure the protection and well-being of indigenous communities and to mitigate the effects of climate change globally.

- Q: How is carbon used in the production of textiles?

- Textile production utilizes carbon in multiple ways, encompassing the utilization of carbon fibers, activated carbon, carbon black, and carbon nanotubes. Carbon fibers, for instance, serve as a lightweight and sturdy reinforcement for fabrics, enhancing their durability and performance. Activated carbon, known for its porous nature, finds extensive use in the textile industry due to its ability to adsorb and eliminate undesirable odors and chemicals. Consequently, it is employed in the manufacturing of sportswear, workwear, and specialized textiles where odor control is crucial. Additionally, carbon black, a finely powdered substance composed of carbon particles, functions as a pigment in textile printing and dyeing. By imparting a deep black hue, it is widely employed in the production of garments, upholstery, and other textiles requiring a dark coloration. Moreover, the development of carbon nanotextiles represents an innovative application of carbon in the textile realm. These textiles, fabricated from carbon nanotubes, exhibit exceptional properties such as high electrical conductivity and thermal stability. Consequently, they are ideal for applications involving wearable electronics, smart textiles, and conductive fabrics. In conclusion, carbon's incorporation into textiles through the integration of carbon fibers, activated carbon, carbon black, and carbon nanotubes contributes significantly to the strength, durability, odor control, coloration, and functionality of various textile types.

- Q: What is the role of carbon in organic chemistry?

- Carbon is the backbone of organic chemistry as it has the unique ability to form covalent bonds with other carbon atoms and a wide variety of other elements, resulting in the vast diversity of organic compounds. It is the element that allows for the formation of complex molecules, such as carbohydrates, proteins, lipids, and nucleic acids, which are essential for life processes.

- Q: What does carbon cloth tonnage mean?

- Carbon cloth tonnage is illegal: mean a square centimeter of sectional area of carbon cloth tension of tonnage. Meaning that the carbon cloth rolled into a solid "rod" if the cross-sectional area of the bar is 1 cm, the maximum tension tonnage it bear -- carbon cloth tonnage.

Send your message to us

Carbon electrode paste graphite paste with high-purity as carbon additive and carburant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords