Cans Making Machinary for Metal Packing Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cans Making Machinary for Metal Packing Use

1.Structure of Description

Cans Making Machinary for Metal Packing Use is the exact machinary used for cans making.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

Good quality

3. Images

4. Specification

Type:Packaging Line

Condition:New

Application:tin cans in various size and shapes, tin bucket in various sizes

Packaging Type:Cartons

Packaging Material:Wood

Automatic Grade:Automatic

Driven Type:Electric

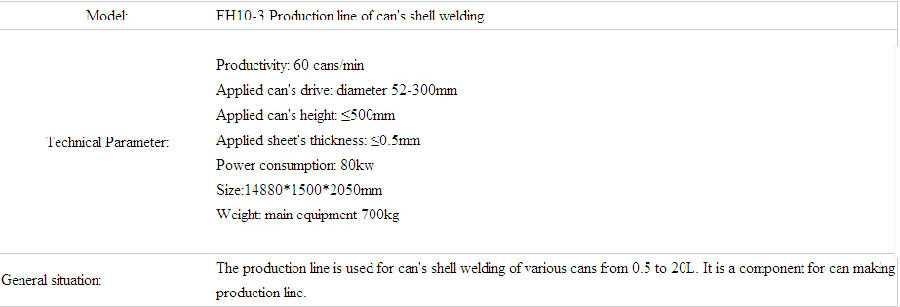

Model Number:FH10-3 Production line of can's shell welding

Color:Green

Size:14880*1500*2050mm

Weight:700kg

Productivity:60 cans/min

Customzed acceptable:Yes

1).NC table

Max. speed of arm and clamp: 36m/min

Feed precision: ±0.1mm

Working voltage: ~380V 50HZ

Rated power: 2KW

Outline size (L×W×H)(NC unit): 1740×2340×1045

Weight (NC unit): 1200kg

(2).35T press

Nominal pressure:350KN

Slide block travel distance:70mm

Number of times of travel:120Times/minute

Power:4KW

Outline size (L×W×H)(mm):1660*1340*2360

Weight:5000Kg

5.FAQ

A. What is the package ? (Referred as below)

It is sea worthy package.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

- Q: What are the main functions of packaging machinery?

- In order to meet the requirements of many customers, our company has learned from all aspects of the role of packaging machinery and equipment, so that we need customers for reference

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Buddy, you go to Taobao to buy a few hundred vacuum packaging machine, the 3 days is no problem, I suggest you go to buy a good brand, this thing hundreds of, garbage is easy to bad, shelf life 3 days, basically no problem

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: What is the working principle of the pillow packing machine?

- In fact, the special machine is often better than the packaging of the compatible machine. A packing machine should be packed in no more than 3-5 varieties. What's more, the products with the larger size and the difference in size should be packed separately as much as possible.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- 5009.101 determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 13113 hygienic standard for polyethylene terephthalate moulding articles for food containers and packaging materials

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard applies to the use of heat sealing glass paper, BOPP, PVC film and other packaging materials, packaging machine for carton box type items or single package or bag or several stacked and wrapped sealing, widely used in food, medicine, tobacco, cosmetics, stationery, audiovisual products etc.. This standard needs to be purchased.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

Cans Making Machinary for Metal Packing Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords