Packing Machinary for cartons

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

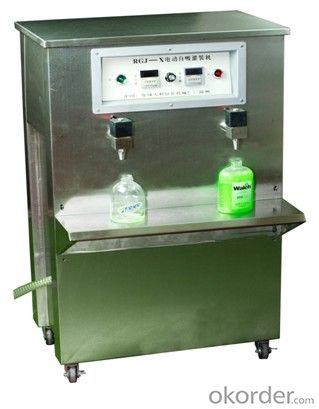

| Type: | Filling Machine | Condition: | New | Application: | Food,Medical,Chemical |

| Packaging Type: | Cartons,Cans | Packaging Material: | Plastic,Metal,Glass,Wood | Automatic Grade: | Automatic |

| Driven Type: | Pneumatic | Voltage: | 3p 380/220v 50/60hz | Power: | 5kw |

| | | | | | |

| Dimension(L*W*H): | 2800*1400*2400 | Weight: | 700kgs | Certification: | ce |

| After-sales Service Provided: | Engineers available to service machinery overseas | Usage: | Outer | use: | General |

| style: | Packing Machine |

Packaging & Delivery

| Packaging Detail: | Seaworthy plywood case |

| Delivery Detail: | 40Days |

Introduction:

This machine is capable of dispensing powder into roundshaped rigid container at line speeds up to 100 bpm ,Multistages filling integrated with check weighing and reject system it provides precise weight control to save expensive product giveaway and featured with high speed and high accuracy.It is widely used in milk powder production line with good outcome and stable performacne.

Specifications:

| | |

Dosing mode | Multi-Stage Filling with inline check weigher and reject system |

Direction | Left to right |

Filling Capacity | 100 - 2000g(With different set of auger and funnel) |

Container Size Range | Φ60-135mm; H 60-260mm |

Fill Accuracy | 100-500g, ≤±1g; ≥500g,≤±2g(Depending upon the density of material) |

Hopper Volume | Big (85L) Small(60L) |

Filling Output | Up to 90-100cans/min(900g) and 110-120 cans/min(400g) |

Power Requirement | 3P AC208-415V 50/60HZ |

Power Supply | 5KW |

Dimensions | 2900mm(L)*1400mm(W)*2500(H) |

Gross Weight | 600KGS(Approx) |

Main Features:

1: Multi-stage filling integrated with inline check weigher and reject system: High

speed ,high accuracy.

2:All parts and assemblies coming in contact with powder are made of S.S.304 and easily

removable for maintenance changeover.

3:NO BOTTLE, NO FILL" System eliminates wastage of costly powder.

4:Conveyor driving is through High quality Gear motor with stable performance.

5: Filling controlled by servo system with adjustable speed and high accuracy outcome.

6: Single track bottle movement, reduces setting of supporting guide rails and

semi skilled person can also easily operate the machine.

7: Pneumatic bottle indexingsystem is connected with auger rotation,

which eliminates chances of bottle transfer before completion of filling operation.

8: No change parts are required for any change in bottle diameter in certain set

range.

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Packing Machinary for cartons

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords