Calcined Petroleum Coke with Mositure 0.5%max

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1010 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.

1) high absorption rate, it can be absorbed up to 90%. Seady supply

2) absorbed more quickly than other carbon additive; no residue remains in furnace.Good quality

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

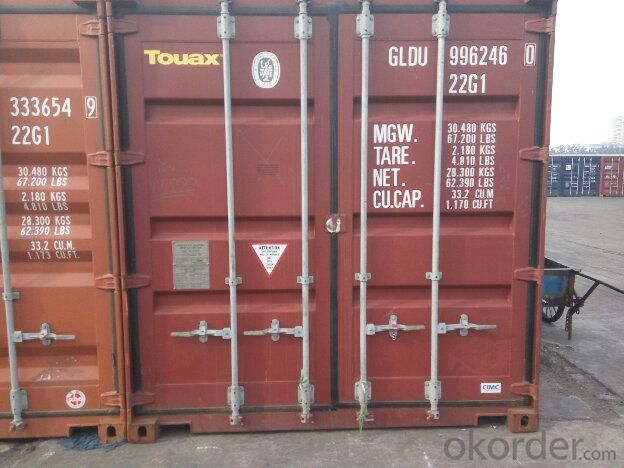

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: How does carbon impact the prevalence of tsunamis?

- Carbon dioxide does not directly impact the prevalence of tsunamis. Tsunamis are primarily caused by undersea earthquakes, volcanic eruptions, or underwater landslides. These events release massive amounts of energy into the water, generating powerful waves that can travel across the ocean and cause devastating destruction when they reach the coast. While carbon dioxide emissions do not directly cause tsunamis, they are linked to climate change, which can indirectly influence the occurrence and impact of these natural disasters. Increased levels of carbon dioxide and other greenhouse gases in the atmosphere contribute to global warming, resulting in rising sea levels. As sea levels rise, coastal areas become more vulnerable to the destructive power of tsunamis, as the waves can penetrate further inland. Furthermore, climate change can also affect the frequency and intensity of extreme weather events, such as hurricanes and tropical storms. These weather patterns can trigger underwater landslides or enhance the chances of volcanic eruptions, both of which can lead to tsunamis. In conclusion, while carbon dioxide emissions do not directly cause tsunamis, they play a role in the broader context of climate change, which can indirectly impact the prevalence and impact of tsunamis through rising sea levels and the potential for more frequent extreme weather events.

- Q: What are the different types of carbon-based polymers?

- There are several different types of carbon-based polymers, including polyethylene, polypropylene, polystyrene, polyvinyl chloride (PVC), and polyurethane.

- Q: What is the carbon emission of the air conditioner?

- Summer less air-conditioning 1 hours, it will reduce carbon emissions of 0.621kg

- Q: How can I see if a battery can be used to recharge it?Can not all carbon batteries charge?

- Maybe you'll ask why you don't unify the voltages of these batteries to 1.5V, you know, from the raw batteries we learned in high schoolThe battery positive electrode and the negative electrode potential (i.e. voltage) is determined by a positive electrode and a negative electrode material and whether the charge is determined by using the different electrolyte electrolyte battery two materials also need to be adjusted accordingly

- Q: How do plants use carbon dioxide?

- Plants use carbon dioxide through a process called photosynthesis, which is vital for their survival. During photosynthesis, plants take in carbon dioxide from the air through small openings on their leaves called stomata. Inside the leaves, carbon dioxide combines with water, which is absorbed by the roots, to produce glucose and oxygen. The glucose is used by the plant as a source of energy to carry out various metabolic processes and to grow. Additionally, plants store excess glucose in the form of starch for future use. The oxygen produced during photosynthesis is released back into the atmosphere, which is crucial for the survival of other living organisms, including humans, as we depend on oxygen for respiration. Therefore, plants play a crucial role in maintaining the balance of carbon dioxide and oxygen in the atmosphere, making them essential for life on Earth.

- Q: What are the impacts of carbon emissions on the stability of mountain glaciers?

- Carbon emissions have significant impacts on the stability of mountain glaciers. As carbon dioxide and other greenhouse gases are released into the atmosphere, they contribute to global warming and climate change. This rise in global temperatures directly affects the stability and health of mountain glaciers. One of the main consequences of increased carbon emissions is the accelerated melting of mountain glaciers. Warmer temperatures cause glaciers to melt at a faster rate, leading to a reduction in their size and volume. This not only affects the aesthetic beauty of these natural wonders but also has major implications for water resources and ecosystems. Mountain glaciers act as natural reservoirs, storing water in the form of ice and releasing it gradually over time. This process helps regulate water flow in rivers and streams, ensuring a steady water supply for downstream communities, agriculture, and ecosystems. However, as carbon emissions contribute to glacier melting, this natural water storage mechanism is disrupted. The loss of glaciers leads to reduced water availability during dry seasons and can result in water scarcity for communities that rely on glacier meltwater. Furthermore, the retreat of mountain glaciers due to carbon emissions has ecological consequences. These glaciers provide critical habitats for various plant and animal species. The loss of glacier ice and associated ecosystems can have a ripple effect on the entire ecosystem, leading to the decline or even extinction of species that depend on glacier-fed environments. The impacts of carbon emissions on mountain glaciers also extend beyond local communities and ecosystems. Glacial meltwater contributes to the overall water supply in many regions around the world. As glaciers shrink and disappear, the availability of water resources becomes uncertain, especially in regions heavily reliant on glacier meltwater. This can potentially lead to conflicts over water resources and exacerbate existing tensions. In conclusion, carbon emissions have detrimental impacts on the stability of mountain glaciers. The accelerated melting of glaciers disrupts water availability, threatens ecosystems, and poses challenges for water resource management. It is crucial to reduce carbon emissions to mitigate these impacts and preserve the integrity and functionality of mountain glaciers.

- Q: How does carbon affect the quality of indoor air?

- Carbon can have a significant impact on the quality of indoor air. One of the main contributors to carbon in indoor air is carbon dioxide (CO2), which is produced through the process of respiration by humans and animals. High levels of CO2 can cause discomfort, as it can lead to feelings of drowsiness, headaches, and difficulty concentrating. In addition to CO2, carbon monoxide (CO) is another carbon compound that can be present in indoor air, mainly due to the incomplete combustion of fossil fuels in stoves, fireplaces, and furnaces. Carbon monoxide is highly toxic and can be life-threatening if present in high concentrations. Apart from these direct sources of carbon, indoor air can also be affected by volatile organic compounds (VOCs), such as formaldehyde, benzene, and toluene. These VOCs are released from various sources like building materials, furniture, cleaning products, and tobacco smoke. They can have adverse health effects, including eye, nose, and throat irritation, headaches, dizziness, and in some cases, even long-term health risks like cancer. To maintain good indoor air quality, it is essential to monitor and control the levels of carbon compounds in the air. Proper ventilation is crucial to ensure fresh air circulation and reduce the concentration of CO2 and other pollutants. Regular maintenance and inspection of fuel-burning appliances can prevent the build-up of carbon monoxide. Using low-VOC or VOC-free materials and products, as well as avoiding smoking indoors, can help minimize the release of harmful carbon compounds.

- Q: How do you remove the carbon stains on your clothes?

- Cleaning instructions for clothing * collar / cuff: Soak clothes in warm water with detergent powder for 15-20 minutes before washing. * Yellow White Sox: soaking washing powder for 30 minutes, then normal washing. * milk stains: use washing powder to do stain pretreatment and normal washing. If the milk stains are stubborn, you may need to use a bleach that is harmless to the clothes. * ordinary oil: a strong detergent is used for pre treatment and normal washing; if desired, bleaching of stubborn stains can also be done with bleach. The clothing removal method of rubber and plastic sex pigment stains with rubber and plastic pigment stains, it is difficult to remove, only use a suitable way to remove. 1, adhesive removal of stains clothes with glue stains, can use acetone or banana on glue water stains, use a brush to repeated washing, until soft glue stains off from the fabric, and then rinse with water. Once, can be repeated scrubbing several times, and finally wash. Do not use this method to avoid fabric damage. 2, white latex stain removal of white latex is a kind of synthetic resin, polyvinyl acetate emulsion. It is characterized by the addition of nylon silk and so on, the vast majority of fiber quality materials have bonding role, it can firmly adhere to the clothing. It has another characteristic that can dissolve in a variety of solutions. We will use its own characteristics to find ways to remove. By 60 DEG C or 8:2 alcohol liquor (95%) and a mixture of water, white glue stains on the clothes soak, soak about half an hour later, you can wash with water scrubbing, until...

- Q: How does carbon dioxide affect the growth of marine organisms?

- Carbon dioxide affects the growth of marine organisms by increasing water acidity, which can hinder their ability to build shells and skeletons, disrupt their reproductive cycles, and ultimately lead to reduced growth and survival rates.

- Q: Organic matter is converted from organic carbon. Why is humus represented by carbon instead of converted?

- Therefore, only there is a certain relationship between soil carbon content and soil organic matter, high carbon content of soil humus certain, but it does not explain the soil organic matter, because organic matter contains not only the humus, also contains many other organic substances are not decomposed.

Send your message to us

Calcined Petroleum Coke with Mositure 0.5%max

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1010 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords