High Purity Al2O3 Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

85 calcined bauxite

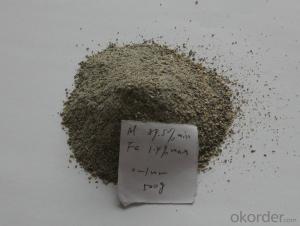

Item | Calcined Bauxite High Purity of Al2O3 |

| Product Description | Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns. |

Size | 0-1mm,1-3mm,3-5mm,200mesh,325mesh,or as buyer's request. |

| Application | 1.Aluminium metallurgy. 2.Precision casting/Investment casting: bauxite grog fines can be made into mold for precision casting. 3.Refractory: high alumina bauxite's refractoriness can reach 1780°C. It is charactered by good chemical stability and mechanical performance.( low Fe2O3) 4.Aluminium silicate refractory fiber: The high alumina bauxite grog can melt under2000°C-2200°C in the electric arc furnace. After a series of processing, it can become aluminium silicate refractory fiber, which can be made into fiber blanket,plate,cloth. 5.Mixing magnesia and bauxite grog with binders to pour the molten steel ladle for better overall lining performance. 6.Producing bauxite cement. 7.Abrasives. 8.Ceramics industry. 9.Chemistry industry for all kinds of aluminium compound. |

| Chemical Composition | GradeAL2O3FE2O3TIO2K2O+Na2OCaO+MgOBulk density7068min≤2.0≤4.0≤0.6≤0.6≥2.757573min≤2.0≤4.0≤0.6≤0.6≥2.758080min≤2.0≤4.0≤0.5≤0.5≥3.258585min≤2.0≤4.0≤0.4≤0.4≥3.0088 87.5min≤1.6≤4.0≤0.4≤0.4≥3.20 |

| Our Service | 1.We can offer you the customer size services. 2.We can offer you the best quanlity and price. 3.We can offer you the related test report,both at factory and the third party. 4.Packaging: 25KG per bag or as client's requirement. 5.We have sufficient manufacturing capability to delivery the goods safely and in time. |

| Our Advantage | 1.24 Years experience of Calcined Bauxite manufacturing and exporting. 2.Our factory is equited with advanced machine,automatic production line, we are in a good position to produce customers size product in large scale with low cost. thus,provide low priced goods. 3.Self-owed mine fo production capacity over 5000MT per month. 4.Professional export team and skilled workers, we are in a good position to serve our customers to the best of our ability. 5.Strictly quality contol at our factory and third party quality inspection before shipment. 6.Cargoes together with container sales service available. 7.Full experience of large numbers containers loading in Chinese sea port. 8.Packing with pallet as buyer's special request. 9.Fast shipment by reputed shipping line. 10.Cargoes photo before and after loading into container. 11.Professional service team keep customers informed from delivery to discharge. |

- Q: Is refractory material harmful to human body?

- Part is harmful to human body, mainly refractory raw material, silica powder inhalation can cause lung tuberculosis, siliceous fiber on the human body does have great harm, in fact, like other inorganic fiber in the inhalation of the trachea or lung after the same harm to human

- Q: Which are fireproofing external wall materials?

- 1. Acording to national standard GB8624-97, the combustion performance of construction materials are classified as: Grade-A: incombustible building material: Grade-A WW thermal insulation material which hardly burns. Grade-B1: nonflammable building material: nonflammable building material has good flame resistance. It is difficult to burn or spread in the air or at high temperature. Grade-B1: nonflammable building material: nonflammable building material has good flame resistance. It is easy to burn in the air or at high temperature, thus spreading the fire, such as wooden column, timber roof truss, timber beam and wooden stairway. Grade-B3: inflammable building material. Without fire resistance, inflammable building material is easy to burn and thus cause a fire. 2. According to fireproofing performance, external wall thermal insulation materials can be classified as: 1. Thermal insulation material with Grade-A combustion performance: WW inorganic thermal insulation material, rock wool, glass wool, foam glass, foamed ceramics and foam cement. 2. Thermal insulation material with Grade-B1 combustion performance: XPS panel after special treatment/ PU, phenolic aldehyde, gelatine powder polyphenyl granule after special treatment. 3. Thermal insulation material with Grade-B2 combustion performance: EPS, XPS, PU, PE, ETC.

- Q: What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q: What's the fire endurance of hollow brick?

- This question is really very simple. It is better no to exceed 1050℃, or it will be easily burnt. I think 980℃ is ok actually. This is the maximum limit.

- Q: Using what kind of melting aluminium furnace refractories is more appropriate?

- If it's the ordinary, you can use high aluminum refractory brick with general clay, GB/T 3994-2005 clay heat insulation refractory brick. If you need these with good material, there is high alumina thermal insulation refractory brick, GB/T 3995-2006 high aluminum heat insulation refractory brick, models have A13 and material is the alumina, A13 50 u, high insulating brick B5.Intermediate insulating brick B2, etc. Dolomite brick: good hang kiln performance, good erosion resistance, but brick is usually without f - CaO, hydration, and difficult to transport and storage, less used in the production. Magnesia-chrome bricks: good hang kiln, used in calcining zone. The disadvantage is that its thermal shock resistance is poor and plus hexavalent Cr is toxic, the production and use of magnesite chrome bricks in international countries gradually reduce. Now unit using the brick find replacements as soon as possible.

- Q: What is the concept of lightweight refractory material?

- Lightweight refractory material has high porosity, mechanical strength and erosion resistance. Compared with normal refractory bricks, it is a kind of refractory material with large volume shrinkage in high temperature, low thermal conductivity and small bulk density. It is used as thermal insulation material in industrial furnace and other thermal equipments. It has poor wear resistancel.

- Q: The performance of refractory material

- As for easticity modulus, you can serach for information on the Internet or specialized books.

- Q: Who can tell somthing about how to choose fire resistant rating of fire resistance rolling shutter doors?

- There is no necessary connection between them. Different fire resistant ratings of bulidings require different fire endurance of different elemements of buildings. According to the fire endurance, fireproof doors can be divided into A-grade, B-grade and C-grade, whose fire endurance should not be less 1.2h, 0.9h and 0.6h respectively. A-grade fireproof doors can be even applied to the material whose fire resistant rating is at secondary level. "Building Regulations" mention that fire resisting shutter can be used as partition of fire?compartment in those places where setting firewalls is not so easy. When using fire resisting shutter whose fire endurance doesn't include unexposed surface temperature rise, it should install closed independent automatic sprinkler system for protection on both sides, and the sprinkler sholud last at least 3 hours.

- Q: What's the material of fireproof and wear-resisting floor?

- 1. It is the kind of special concrete floor, and its production process is the same with that of the common concrete floor, but it uses different material which needs to be the pebbles and sand after processing with marbles and dolomite. 2. Fireproof floor is a kind of decorative material which is laid on the ground of the factory or large areas of floors. It does not support combustion or it is composed of flame retardant materials. Fireproof floor has two categories. One is composed of aggregate wear-resistant material which is solid particulate matter. Its construction method is to evenly spread aggregate wear-resistant particles on the surface layer of the concrete when the floor is just pouring concrete and solidified, and then a firm flame retardant layer will be formed on the surface layer. This is the the so-called carborundum wear-resisting floor. But this kind of material has many limitations and can only be used on the surface of the just poured concrete. In addition, it is easy to fade in color and not beautiful in appearance. So this is not fireproof floor in the strict sense. Here we focus on a new liquid coating fire protection floor, which is environment friendly, widely used and beautiful in appearance. 3. Wear-resistant floor has the characteristics of pressure resistance, strong wear resistance,oil resistance, and anti-infiltration. It is also dust-free and easy to clean. After entering the initial setting of concrete, construction can be started immediately. Construction period is usually longer, but better using effect will arise.

- Q: What kinds of fireproof materials does the safe use?

- The fireproof materials of safe, copper is one of the most widely used material of locks for its good mechanical performance, corrosion resistance and processibility and beautiful colors.

Send your message to us

High Purity Al2O3 Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords