Calcined Anthracite Coal FC 90-95% for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

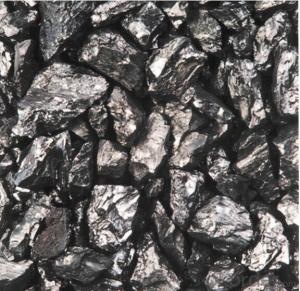

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Calcined Coal FC 90-95% for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Calcined Coal FC 90-95% for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Calcined Coal FC 90-95% for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

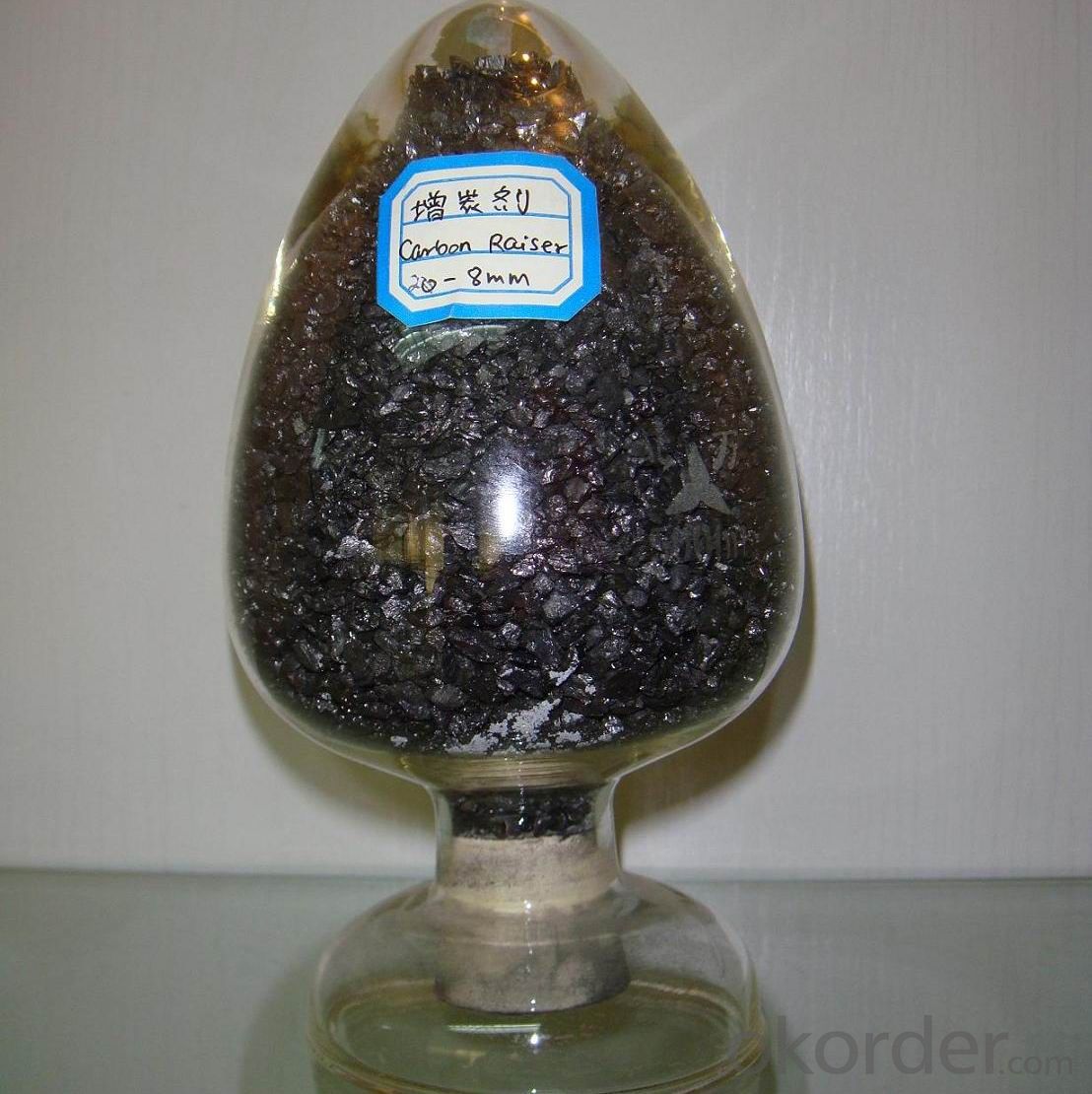

Image

Calcined Coal FC 90-95% for Steelmaking

FAQ:

Calcined Coal FC 90-95% for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Calcined Coal FC 90-95% for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: Which is better, 13 and 14 carbon breath tests?

- Two kinds of carbon synthesis conditions are different, the instruments are not the same, so lead to price differences

- Q: What is the relationship between carbon and climate change?

- The relationship between carbon and climate change is that carbon dioxide (CO2), primarily emitted through human activities such as burning fossil fuels, is a greenhouse gas that contributes to the warming of the Earth's atmosphere. The excessive release of CO2 traps heat, leading to a rise in global temperatures and subsequent climate change impacts such as melting ice caps, rising sea levels, extreme weather events, and disruptions to ecosystems.

- Q: What are the different types of carbon-based plastics?

- There are several different types of carbon-based plastics, each with unique properties and applications. Some common types include: 1. Polyethylene (PE): This is the most widely used plastic and can be found in various forms such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). PE is known for its strength, flexibility, and resistance to chemicals, making it suitable for applications like packaging, pipes, and toys. 2. Polypropylene (PP): PP is another popular plastic known for its high melting point, chemical resistance, and durability. It is commonly used in automotive parts, appliances, and packaging. 3. Polystyrene (PS): PS is a rigid plastic that is often used in disposable products like food containers and packaging materials. It is lightweight and has good insulation properties. 4. Polyvinyl Chloride (PVC): PVC is a versatile plastic that can be rigid or flexible depending on its formulation. It is commonly used in construction materials, pipes, cables, and vinyl flooring. 5. Polyethylene Terephthalate (PET): PET is a strong and lightweight plastic that is commonly used in beverage bottles, food packaging, and textile fibers. It is known for its excellent gas and moisture barrier properties. 6. Polycarbonate (PC): PC is a transparent plastic known for its high impact resistance and heat resistance. It is often used in eyewear, automotive parts, and electronic devices. These are just a few examples of carbon-based plastics, and there are many other variations and blends available in the market. The choice of plastic depends on its intended application, desired properties, and environmental considerations.

- Q: A carbon Roast Lamb Leg stores need to how much money

- You can go to see the Roast Lamb Leg hunting flavor, taste and scale are good, no technology can also go to learn.

- Q: What are the carbon monoxide collection methods?

- Drainage methodExhaust air cannot be used because CO is poisonous

- Q: How do humans contribute to carbon emissions?

- There are several ways in which humans contribute to carbon emissions. One significant source of carbon emissions arises from the burning of fossil fuels for electricity, transportation, and heating purposes. This involves the combustion of coal, oil, and natural gas, resulting in the release of carbon dioxide (CO2) into the atmosphere. The use of these fossil fuels is widespread in our everyday lives, from powering our homes and vehicles to manufacturing goods and producing food. Furthermore, deforestation, which is primarily caused by human activities such as agriculture, logging, and urbanization, also adds to carbon emissions. Trees absorb CO2 and release oxygen, so when they are cut down, the stored carbon is released back into the atmosphere. Additionally, industrial processes like cement production and chemical manufacturing also emit significant quantities of CO2. Lastly, the livestock industry, particularly the production of beef and dairy products, contributes to carbon emissions through the release of methane from livestock and the deforestation required to expand grazing areas and cultivate animal feed. In conclusion, human activities directly and indirectly contribute to carbon emissions, underscoring the necessity for collective efforts to mitigate and reduce our environmental impact.

- Q: How does carbon affect the formation of hurricanes?

- Carbon does not directly affect the formation of hurricanes, as their development is primarily influenced by factors such as warm ocean temperatures, atmospheric instability, and moisture content. However, carbon emissions and climate change can indirectly impact hurricanes by contributing to rising sea levels, which can exacerbate storm surge flooding during a hurricane event. Additionally, some studies suggest that climate change may lead to more intense hurricanes in the future, although the exact relationship between carbon and hurricane intensity is still an active area of research.

- Q: What is carbon nanophotonics?

- The study and manipulation of light at the nanoscale using carbon-based materials is known as carbon nanophotonics. This branch of science and technology integrates carbon nanotubes, graphene, and diamond nanoparticles with photonics to develop new optical devices and systems. Carbon-based nanomaterials possess exceptional electrical conductivity, high mechanical strength, and excellent optical properties, making them ideal for nanophotonics applications. These materials can confine and manipulate light at the nanoscale, enabling the miniaturization of optical components and enhancing light-matter interactions. Carbon nanophotonics has vast potential across various fields. Telecommunications, for instance, can benefit from high-speed and compact photonic devices developed using carbon nanomaterials for efficient data transmission. In the field of sensing, highly sensitive and selective sensors can be developed using carbon nanophotonics to detect different molecules and substances. Furthermore, carbon nanomaterials can enhance the efficiency of solar cells and other photovoltaic devices, contributing to advancements in energy harvesting. In summary, carbon nanophotonics is a rapidly evolving field that combines carbon-based nanomaterials with photonics to create innovative optical technologies. By harnessing the power of light at the nanoscale, this field has the potential to revolutionize industries and drive advancements in science and technology.

- Q: How does carbon affect the formation of blizzards?

- Carbon does not directly affect the formation of blizzards. Blizzards are primarily caused by the collision of warm and cold air masses, resulting in heavy snowfall and strong winds. However, carbon emissions and climate change can influence weather patterns, potentially leading to more intense or frequent blizzards in certain regions due to alterations in atmospheric conditions.

- Q: The relative molecular mass was between 120-150. The testThe organic matter M, which contains only carbon, hydrogen and oxygen, was measured by mass spectrometer. The relative molecular mass was between 120-150. The mass fraction of oxygen element measured by experiment is 48.48%, the ratio of hydrocarbon to mass is 15:2, and only COOH in M molecule is measured by infrared spectrometer. Then the M formula is?

- The mass fraction of oxygen element is 48.48%, the mass fraction of hydrocarbon is =51.52%, and the mass ratio is 15:2. The mass fraction of carbon is =51.52%x15/ (15+2) =45.46%, and the mass fraction of hydrogen is =51.52%x2/ (15+2) =6.06%The atomic number of C, H and O is higher than that of =45.46%/12:6.06%/1:48.48%/16=3.79:6.06:3.03Molecules contain only COOH, and oxygen atoms must be even numbers.Therefore, the number of atoms in C, H and O can be reduced to =5:8:4, which may be C5H8O4, and the relative molecular weight is 132

Send your message to us

Calcined Anthracite Coal FC 90-95% for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches