C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

C Channel Steel (Height: 50–400mm)

OKorder is offering high quality C Channel Steel (Height: 50–400mm) at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

C Channel Steel (Height: 50–400mm) is ideal for use in the construction of ships, vessels and other steel structures.

Product Advantages:

OKorder's Channel Steel is durable, strong, and resists corrosion. Additionally, our steel is easily assembled with the assistance of trained engineers.

Main Product Features:

· Short construction period

· Strong

· Experienced engineer assistance

· ISO9001 & SGS certification

· Easy to assemble and dismantle

· Can be recycled and reused

Product Specifications:

Ordinary Model

Height: | 50 – 400mm |

Thickness: | 4.5 – 14.5mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 37 X 4.5mm—400 X 104 X 14.5mm |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

Light Model

Height: | 50 – 400mm |

Thickness: | 4.4 – 8.0mm |

Surface: | Painted, Galvanized, As per customer request |

Length: | As per customer request |

Size: | 50 X 32 X 4.4mm – 400 X 115 X 8.0mm . |

Punch: | Can be punched as per customer request |

Material: | Q195 / Q235 / Q215 / Q345 / SS400 / S235JR, A36, SS400, SS540 ASTM A36 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

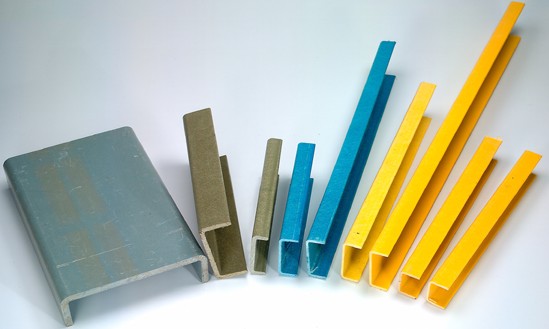

Images:

- Q: Can steel channels be used for access ladders?

- Yes, steel channels can be used for access ladders. Steel channels are strong and durable, making them suitable for supporting the weight of individuals climbing up and down the ladder. Additionally, their shape provides stability and rigidity, ensuring a safe and secure ladder structure for accessing elevated areas.

- Q: What are the common loadings considered in the design of steel channels?

- In the design of steel channels, there are several common loadings that are typically considered. These loadings include dead load, live load, wind load, and seismic load. 1. Dead load: Dead load refers to the weight of the structure itself and any permanent fixtures or equipment. In the case of steel channels, this would include the weight of the channel itself, as well as any additional components attached to it. Dead load is a constant and is typically calculated based on the weight of the materials used in the construction. 2. Live load: Live load refers to the weight or load that is temporary and can vary in magnitude. This includes any moving or variable loads that the steel channels may be subjected to, such as people, vehicles, or equipment. Live loads are usually specified by building codes or industry standards and can vary depending on the specific application. 3. Wind load: Wind load refers to the forces exerted on the steel channels by wind. The magnitude of wind load depends on factors such as the height of the structure, the shape and orientation of the channels, and the local wind speed. It is important to consider wind load in the design of steel channels to ensure structural stability and safety. 4. Seismic load: Seismic load refers to the forces generated by earthquakes or other seismic events. These forces can cause significant stress and deformation in steel channels. The design of steel channels should take into account the seismic risk of the location and the expected ground motion to ensure that the channels can withstand these forces and maintain structural integrity. Overall, these common loadings are considered in the design of steel channels to ensure that they can safely support the intended loads and meet the required structural performance criteria. Proper consideration and analysis of these loadings help engineers design channels that are structurally sound and can withstand the forces they are subjected to in real-world conditions.

- Q: Cautions for surface zinc spraying on channel steel

- In the liquid zinc galvanizing state, through physical and chemical processes is quite complicated, not only in the steel plating thick pure zinc layer, but also generate a Zn Fe alloy layer. This plating method not only has galvanized corrosion characteristics, and because of the zinc iron alloy layer. It also has strong corrosion resistance which can not be compared with galvanized. Therefore, the plating method is especially suitable for various strong acids, alkalis, fog and other corrosive environments.

- Q: The parameters of the channel steel of Q235B

- Q235B is carbon structural steelIt consists of Q+ numeral + quality grade symbol + deoxidization method symbol. The steel dubbed "Q", representing the yield point of steel, behind the digital representation of the yield point value, in units of MPa such as Q235 (s) said the yield point for carbon steel 235 MPa. The necessary grades can be marked behind said deoxidation methods of quality grades and symbols. The quality class symbols are A, B, C, and D respectively. Deoxidation method notation: F means boiling steel; B represents semi killed steel: Z indicates calm steel; TZ stands for special sedation steel; calm steel is not marked; Z and TZ are not standard. For example, Q235-AF indicates a class of rimmed steel.

- Q: Can steel channels be used in the agricultural parts manufacturing industry?

- Yes, steel channels can be used in the agricultural parts manufacturing industry. Steel channels are versatile and strong, making them suitable for various applications in agricultural machinery and equipment. They can be used for constructing frames, supports, brackets, and other structural components in the manufacturing of agricultural parts.

- Q: Can steel channels be used for creating storage racks or shelving units?

- Yes, steel channels can certainly be used for creating storage racks or shelving units. Steel channels are known for their strength and durability, making them ideal for supporting heavy loads. They can be easily fabricated and assembled to create sturdy and long-lasting storage solutions. The versatility of steel channels allows for customization and adaptation to specific storage requirements, such as adjustable shelving heights or different rack configurations. Moreover, steel channels can withstand challenging environments, including warehouses, garages, or industrial settings, ensuring the stability and safety of the storage racks or shelving units.

- Q: How do steel channels contribute to the stability of roofing structures?

- Steel channels contribute to the stability of roofing structures in several ways. Firstly, steel channels are commonly used as purlins, which are horizontal beams that provide support and stability to the roof. These purlins are typically placed perpendicular to the rafters or trusses and are attached to them, creating a strong and rigid framework. The steel channels distribute the weight of the roof evenly across the structure, preventing excessive deflection and ensuring the overall stability of the roofing system. Moreover, steel channels are known for their high strength-to-weight ratio, which means they can support heavy loads without adding excessive weight to the structure. This is particularly important in roofing structures, as they need to bear the weight of the roof materials, such as tiles or metal sheets, as well as any additional loads, such as snow or wind. The use of steel channels allows for the construction of lightweight yet sturdy roofs, enhancing the overall stability of the structure. Furthermore, steel channels provide resistance against structural movements and deformations. They help to prevent sagging or buckling of the roof, which can occur due to the constant exposure to external forces, such as wind or seismic activity. The rigidity and strength of steel channels make them highly resistant to bending or warping, ensuring that the roof remains stable and secure over time. In addition, steel channels offer durability and longevity to roofing structures. They are resistant to corrosion, rust, and decay, which can be common issues in roofing materials exposed to the elements. This resistance ensures that the steel channels maintain their structural integrity, allowing the roof to remain stable and functional for an extended period. Overall, the use of steel channels in roofing structures significantly contributes to their stability by providing a strong, lightweight, and rigid framework. These channels distribute the weight evenly, resist structural movements, and offer durability, ensuring a stable and long-lasting roofing system.

- Q: What are the types of channel steels?

- Channel specification, model and theoretical weight table, channel steel is a strip of steel with a cross section. The representation of specifications, such as a*b*c (where a, B, C on behalf of the letters, no other meaning, and the relationship between letters), said waist height is a mm, B mm wide leg channel, channel waist thickness of C mm, or (a/10) # channel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25a#, 25b#, 25c# and so on.

- Q: How do steel channels contribute to LEED certification?

- Steel channels can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, steel is a highly sustainable material as it is recyclable and can be used in multiple construction projects, reducing the demand for new materials. This aspect aligns with the LEED principle of minimizing waste and promoting resource efficiency. Additionally, steel channels can be manufactured with a high percentage of recycled content, which can earn points towards LEED certification under the Materials and Resources category. Using recycled steel channels reduces the need for extracting and processing raw materials, resulting in a lower carbon footprint and reduced environmental impact. Steel channels can also contribute to energy efficiency in buildings. Steel has excellent thermal conductivity, which allows it to efficiently conduct heat. This property can be utilized in building designs to enhance the overall energy performance of the structure. For example, steel channels can be used in radiant heating and cooling systems, improving energy efficiency and reducing the reliance on traditional HVAC systems. Furthermore, steel channels can provide structural integrity to buildings, ensuring long-term durability and resilience. This durability reduces the need for frequent repairs or replacements, which can contribute to a lower environmental impact and reduced waste generation over the building's lifecycle. In conclusion, steel channels contribute to LEED certification by offering sustainable attributes such as recyclability, high recycled content, energy efficiency, and long-term durability. By incorporating steel channels into construction projects, builders and designers can contribute to a greener and more sustainable built environment, aligning with the goals and principles of LEED certification.

- Q: Are there any limitations to using steel channels in construction?

- Yes, there are limitations to using steel channels in construction. Some of the limitations include: 1. Weight: Steel channels can be quite heavy, which can pose challenges during transportation and installation. It may require specialized equipment and additional manpower to handle and install. 2. Cost: Steel channels can be relatively expensive compared to other construction materials. The cost of steel, especially if it is of high quality, can significantly impact the overall project budget. 3. Corrosion: Steel channels are prone to corrosion, especially in humid or coastal areas. If not properly protected or maintained, they can rust and deteriorate over time, compromising their structural integrity. 4. Thermal conductivity: Steel has high thermal conductivity, meaning it can transfer heat quickly. This can result in poor insulation properties and increased energy consumption for cooling or heating purposes. 5. Fire resistance: While steel is a non-combustible material, it loses strength and can deform under high temperatures. Without proper fireproofing measures, steel channels may not provide sufficient fire resistance, which can jeopardize the safety of the structure. 6. Design limitations: Steel channels are available in a variety of sizes and shapes, but there may still be limitations in terms of design flexibility. Complex or intricate designs may be more challenging or costly to achieve using steel channels. 7. Environmental impact: The production of steel channels requires significant energy and resources, which can have a negative environmental impact. Additionally, steel is not a renewable resource, and its extraction can contribute to deforestation and habitat destruction. It is important to consider these limitations and evaluate alternative materials or design solutions when planning a construction project to ensure the best possible outcomes in terms of cost, safety, and sustainability.

Send your message to us

C Channel Steel (Height: 50–400mm)

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 42000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords