Butterfly Valve Stainless Steel Threaded Directional on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

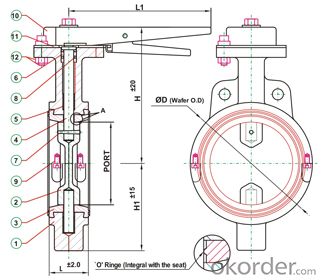

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Valve connections - two how do different connections work?

- The inlet and outlet of valve are respectively connected in two different ways: one end adopts flange connection, the other end adopts thread or socket.

- Q: What does "TD671F" mean?

- You should type is wrong, or I should be D671F, with very limited knowledge and scanty information, this type of mean (D) pneumatic butterfly valve (6) of the clip (7) sealed the middle (1) fluorine plastic (F). There should also be a number of pressure figures and body material. For example, D671F-10C later means that the pressure is 10 kilograms (or 1.0MPa) and C represents the carbon steel

- Q: What does valve J41H-16C mean?

- J- stop valve4- flange type connection1- structure typeH- alloy steel seal16- nominal pressure 16 kgC- body carbon steel

- Q: What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- The difference between the three is as follows: pneumatic valve]: driven by compressed air valve. Operation principle: the pneumatic control valve is composed of actuating mechanism and regulating mechanism. The actuating mechanism is a thrust component of the regulating valve, which generates the corresponding thrust according to the pressure of the control signal, and drives the regulating mechanism to move. The valve body is the regulating component of the pneumatic control valve. It contacts the regulating medium directly and regulates the flow of the fluid. [hydraulic valve]: the use of oil and other liquid pressure driven valve. The working principle of the hydraulic valve control valve pressure control valve flow control valve control valve control valve to control the direction of hydraulic system oil flow direction or liquid flow through the valve two, the working principle of the valve core and the valve body and valve off valve two-way hydraulic lock check valve to make oil movement off or on, changing the direction of the oil flow, so as to realize the hydraulic actuator and its driving mechanism of starting and stopping or changing the direction of movement. [electric valve]: with electric actuators to control the valve, so as to achieve the valve opening and closing. The utility model can be divided into two parts, the upper part of which is an electric executor, and the lower half of which is a valve. Also called air conditioning valve. The electric valve is usually connected by the electric actuator and the valve, and it becomes an electric valve after installation and debugging. The electric valve uses the electric energy as the power to switch on the electric actuator to drive the valve and realize the valve switching and regulating action. So as to achieve the purpose of switching or regulating the pipeline medium.

- Q: According to the original valve installed on it, but never demolished, I am afraid to force over, will not be broken? The old valve, that part of the remaining three tubes tight.

- 1. Prepare the glue and saw blade. Disengaging bracket.2, using a hand saw from the valve mouth (spool near) transverse incision.3, the center will be on the move, the longitudinal incision, be careful not to damage the inner tube.4. Clean the pipe mouth, pipe and new valve coating, install the valve.Turn left and turn right |

- Q: Air compressor out of the gas with what kind of valve control okay, globe valve or other?

- What's the use of your air compressor? Is it manual or automatic? By the way, I think it's ok if the demand is not very strictWhat we used on board was the cut-off.

- Q: Automatic exhaust valve installed in the pipe before and after the installation of other valves need to press it?

- Do not need ah, at most installed a gate valve, globe valve, and so on, installed on the exhaust valve on the line.

- Q: What does the valve QF mean?

- Valve type, one of the contents, Q refers to the ball valve, F refers to the F-4 seals.

- Q: What kind of valves are best used for sand drain valves?

- Refinement of the Chinese market demand for the valve, like a Pyramid structure. Spire for all imported products, quality, precision, high prices, small amount of monopoly high-end users. The central part of the tower is a wholly foreign-owned and joint venture site, which corresponds to medium and high-end customers who require high quality valves and moderate prices. As for domestic enterprises, they are basically hovering at the bottom of the tower, vying for low-end users in the form of quantity and price. With the increasing rationalization of user purchasing behavior in China, more and more attention has been paid to brand and quality, and the products of sole proprietorship and joint ventures are becoming more and more popular. At the same time, the sole proprietorship and the joint venture enterprises have gradually eroded the market share of the imported products by improving the quality and reducing the cost.

- Q: What's the material of j41h-16p's valve?

- The j41h-16p valve is a stainless steel globe valve.The working principle of stop valve:The cut-off valve, also called the door, is the most widely used as a valve, it is popular is because the process of opening and closing the sealing surface friction between the small, more durable, highly open small, easy manufacture, convenient maintenance, not only for low pressure, but also suitable for high pressure.The closing principle of the valve is to rely on the valve bar pressure, so that the valve sealing surface and seat sealing surface close together, to prevent the circulation of media.The one-way valve can only medium flow direction when installing. The structure length of the stop valve is larger than that of the gate valve, and the fluid resistance is large, and the reliability of the sealing is not strong during the long-term operation.

Send your message to us

Butterfly Valve Stainless Steel Threaded Directional on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords