Building Hoist SC200/200 China Famous Factory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist SC200/200 China Famous Factory

The mast is the force-bearing part of the hoist, also serves as the guiding rail for the cage running. Each mast section is connected with 8.8-level high strength bolts to make up the required height. The mast section, which has superior quality and significant bearing ability, is produced with quality Q235Φ76 seamless steel pipe.

The rack is the major force-bearing part mounted on the mast section, whose material has the same quality with the train wheels, after being tempered and long-time carburized, making it wear-resistant, high-ductile and long life-span.

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

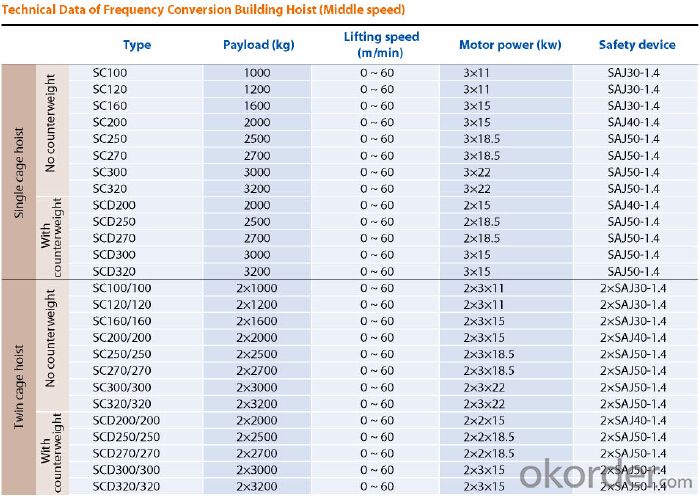

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks whether building hoists can be utilized in limited areas like rooms or tunnels.

- <p>Yes, building hoists can be used in confined spaces such as rooms or tunnels, but it depends on the specific design and size of the hoist. Compact and portable hoists are available for use in tight spaces. However, safety considerations, space dimensions, and the weight capacity of the hoist must be taken into account. It's crucial to ensure that the hoist is suitable for the confined area and that all safety protocols are followed to prevent accidents.</p>

- Q: This question seeks to understand the distinctions among various types of building hoists, which are essential in construction for lifting materials.

- <p>Building hoists, also known as construction hoists, are crucial for transporting materials and personnel in construction projects. The main types include: 1) Goods Hoists, designed for lifting materials and equipment, often with a higher load capacity. 2) Personnel Hoists, specifically for workers, prioritize safety features. 3) Material Hoists, a combination of goods and personnel hoists, allowing both material transport and worker movement. 4) Electric Chain Hoists, powered by electricity, known for their efficiency and control. 5) Manual Chain Hoists, requiring manual operation, useful in areas with no power supply. 6) Electric Winch Hoists, offering high lifting speeds and capacities. Each type varies in capacity, speed, control mechanisms, and power source, impacting their suitability for specific construction needs.</p>

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: What are alternative uses for a building hoist besides construction?

- <p>Yes, a building hoist can be used for purposes other than construction. It can be utilized for moving heavy equipment in industrial settings, transporting goods in warehouses, or even in emergency services for rescue operations. Its ability to lift and lower heavy loads makes it versatile for various applications where vertical transportation is required. However, it's crucial to ensure that any alternative use complies with safety regulations and the hoist's operational specifications.</p>

- Q: The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- Congratulations, it's a tragedy when you want to start the tower

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of hydraulic lifting equipment.

- <p>Hydraulic lifting equipment offers several advantages, including high force generation, compact design, and precise control. It is energy-efficient and can handle heavy loads with ease. The systems are also known for their durability and low maintenance requirements. However, there are disadvantages such as sensitivity to leaks and the need for regular fluid checks. They can be complex to install and maintain, and the equipment can be costly. Additionally, hydraulic systems are sensitive to temperature changes, which can affect performance.</p>

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

- Q: What is the capability of a building hoist in terms of lifting large objects?

- <p>Yes, building hoists are designed to lift and transport large objects in construction settings. They have a high load capacity, often ranging from several hundred to several thousand kilograms, depending on the model and specifications. Building hoists are equipped with safety features to ensure secure lifting and are commonly used for moving materials such as cement, bricks, and heavy equipment within multi-story buildings under construction. However, it's crucial to adhere to the manufacturer's guidelines regarding weight limits and safety protocols to prevent accidents.</p>

Send your message to us

Building Hoist SC200/200 China Famous Factory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords