Building Hoist Construction Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2500 Lifting Speed(m/min):0~60 Motor Power(kw): 3*18.5

Safety Device: SAJ50-1.4 Cage: Single Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SC250

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Inverter we use China famous brand or based on your requirement, Yaskawa, Siemens and Schneider are available

● The material of the rack is tempered steel and pinion is No.60 trainwheel steel.

● The weight of 450x450x1508mm mast section is around 70kg and 650x650x1508mm is about 120kg.

● Self erecting by adding mast section by the lifting device on the tope of the cage. The max loading capacity is 200kg.

Building Hoist Images

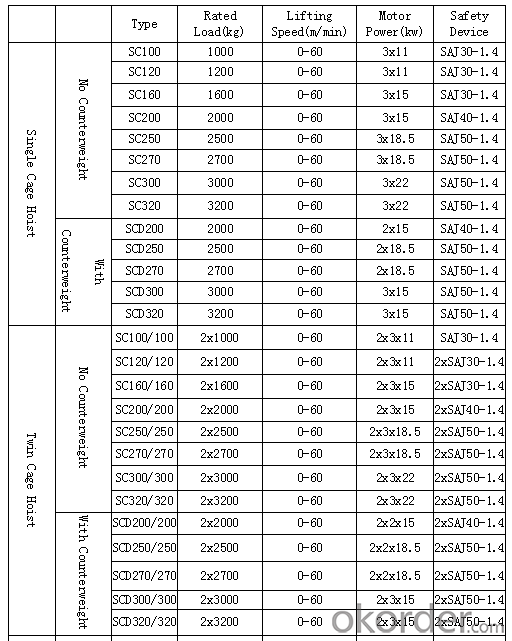

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to use a building hoist for material transportation in both indoor and outdoor environments, especially in confined spaces within industrial zones?

- <p>Yes, building hoists can be used both indoors and outdoors in industrial areas, even with limited space. They are designed for material transportation during construction and are adaptable to various environments. For indoor use, hoists are often enclosed to protect from weather and debris. Outdoors, they may require additional weatherproofing. In confined spaces, compact and tower hoists are used to save space. However, safety regulations and space constraints must be considered to ensure proper installation and operation.</p>

- Q: What are the primary parts that make up a building hoist system?

- <p>The main components of a building hoist include the hoist machine, which is the driving mechanism; the hoist shaft, a vertical structure that houses the hoist; the lifting platform or cage, which carries materials and personnel; the mast or tower, providing support and stability; the counterweight, which balances the load; safety devices such as limit switches and brakes; the control system for operation; and the electrical system that powers the hoist. Additionally, there are guide rails, cables, and buffers that ensure smooth and safe operation.</p>

- Q: The user is asking if it's possible to substitute a hydraulic lifting device for a building hoist in construction.

- <p>Yes, a hydraulic lifting device can be used as an alternative to a building hoist in certain scenarios. Hydraulic devices offer precise control and smooth operation, which can be advantageous for lifting heavy construction materials. However, it's important to consider the specific requirements of your project, such as the weight and size of the materials to be lifted, the height of the lift, and the frequency of use. Hydraulic systems are generally more expensive and require more maintenance than building hoists, but they can provide greater lifting capacity and versatility. Always ensure that any lifting device used complies with safety standards and regulations.</p>

- Q: This question asks about the different types of hydraulic cylinders that are utilized in lifting equipment.

- <p>Hydraulic cylinders used in lifting equipment can be categorized into several types based on their design and application. The main types include: single-acting cylinders, which have one port for fluid and rely on the load or a spring to return; double-acting cylinders, which have ports on both ends and can extend and retract through fluid pressure; telescopic cylinders, which consist of multiple stages that can extend sequentially for greater reach; and rotary hydraulic cylinders, which provide a combination of linear and rotary motion. Each type is chosen based on the specific requirements of the lifting task, such as the need for speed, force, and control.</p>

- Q: This question asks for methods to protect lifting equipment from damage while it is being transported or stored.

- <p>To prevent damage to lifting equipment during transportation or storage, follow these guidelines: 1. Use protective covers or wraps to shield equipment from environmental elements. 2. Securely fasten equipment to prevent movement during transit. 3. Store equipment in a dry, clean area to avoid rust and dirt accumulation. 4. Regularly inspect equipment for signs of wear or damage before and after use. 5. Follow the manufacturer's guidelines for weight limits and proper handling. 6. Use padding or cushioning materials to protect equipment from impacts. 7. Ensure that all parts are properly lubricated to prevent rust and facilitate smooth operation. By adhering to these practices, you can significantly reduce the risk of damage to lifting equipment.</p>

- Q: Can a building hoist experience failure due to mechanical problems or the natural aging process?

- <p>Yes, a building hoist can malfunction due to mechanical issues or wear and tear. Mechanical problems can arise from various factors such as poor maintenance, overloading, or manufacturing defects. Wear and tear, which is the gradual deterioration of a machine's parts over time, can also lead to malfunctions. Regular inspections and maintenance are crucial to identify and rectify these issues, ensuring the safety and efficiency of the hoist operation.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: Is it possible to employ a building hoist for demolition purposes?

- <p>While a building hoist is primarily designed for construction purposes, such as lifting materials and personnel to different floors, it is not typically recommended for demolition work. Demolition requires specialized equipment that can handle the specific stresses and hazards associated with breaking down structures. Using a building hoist for demolition could be dangerous and may not comply with safety regulations. It's crucial to use equipment specifically designed for demolition tasks to ensure the safety of workers and the effectiveness of the operation.</p>

- Q: Should a fire extinguisher be equipped in the construction elevator?

- The dual-purpose construction elevator should be needed

- Q: Helped wall bar how to set up, and several layers of set a, two width, wall rod need a few meters long, what shape is the embedded parts, how much of a steel bar, Angle and wall vertical or have?

- Direct contact with the elevator company, and they give you a plan for the construction of a pre-buried piece, and the parameters of each elevator are different,

Send your message to us

Building Hoist Construction Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords