Construction Hoist Safety Device for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The electric parts adopt products from worl renowned manufacturers such as Schneider, Siemes, and LG. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The surface of the structure can apply paint-spray, parkerizing baking finish or hot galvanizing processing according to users requirments.

Main Features of Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 33 | 2*2*11 | 2*SAJ30-1.2 |

| SC120/120 | 2*1200 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC160/160 | 2*1600 | 33 | 2*2*11 | 2*SAJ30-1.2 | ||

| SC200/200 | 2*2000 | 33 | 2*3*11 | 2*SAJ40-1.2 | ||

| SC250/250 | 2*2500 | 33 | 2*3*11 | 2*SAJ50-1.2 | ||

| SC270/270 | 2*2700 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC300/300 | 2*3000 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| SC320/320 | 2*3200 | 33 | 2*3*15 | 2*SAJ50-1.2 | ||

| With Counterweight | SCD200/200 | 2*2000 | 33 | 2*2*11 | 2*SAJ40-1.2 | |

| SCD250/250 | 2*2500 | 33 | 2*2*11 | 2*SAJ50-1.2 | ||

| SCD270/270 | 2*2700 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD300/300 | 2*3000 | 33 | 2*2*15 | 2*SAJ50-1.2 | ||

| SCD320/320 | 2*3200 | 33 | 2*2*15 | 2*SAJ50-1.2 |

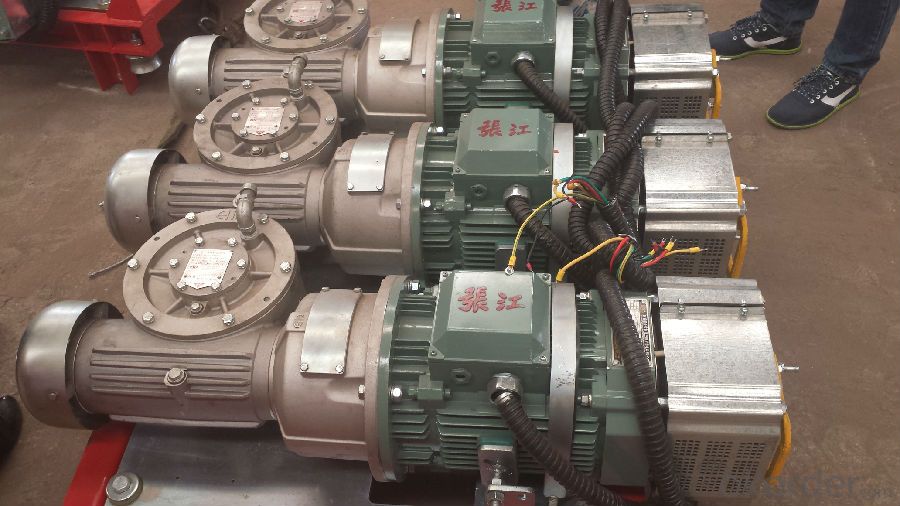

Images of Construction Hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a guide on how to change the tightness of the ropes on a construction hoist.

- <p>Adjusting the tension on a building hoist involves several steps. First, ensure the hoist is powered off and secured to prevent any movement. Locate the rope tensioning mechanism, often found at the base or top of the hoist. This could be a ratchet system, a spring-loaded mechanism, or a manual adjustment bolt. For ratchet systems, adjust the tension by turning the ratchet handle to tighten or loosen the rope. For spring-loaded mechanisms, adjust the spring tension by turning the adjustment bolt. Ensure the rope is properly seated in the pulley system and not frayed or damaged. After adjusting, test the hoist with a small load to ensure the tension is appropriate and the hoist operates smoothly. Always refer to the manufacturer's manual for specific instructions and safety precautions.</p>

- Q: This question asks about the process of installing a building hoist, a piece of equipment used in construction to lift materials and personnel.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the area is level and stable. 2) Unpacking and inspection of the hoist components. 3) Assembling the hoist tower, starting with the base and working upwards. 4) Installing the drive mechanism and control panel. 5) Rigging the hoist cables and safety devices. 6) Conducting a thorough inspection and testing the hoist to ensure it operates safely. 7) Obtaining any necessary permits and approvals. 8) Training operators on the safe use of the hoist. Always follow the manufacturer's instructions and local regulations when installing a building hoist.</p>

- Q: This question asks for steps to ensure that lifting equipment is safe and reliable before it is used.

- <p>To ensure your lifting equipment is safe and reliable before use, follow these steps: Inspect the equipment for any visible damage or wear. Check all safety features such as hooks, cables, and brakes. Ensure that the equipment is properly maintained and serviced according to the manufacturer's guidelines. Verify that all safety certifications and inspection records are up to date. Conduct a thorough pre-use check, including testing the equipment's lifting capacity and stability. Ensure that all operators are trained and certified to use the equipment. Never use equipment that has not been inspected or is showing signs of damage. Always follow the manufacturer's guidelines and safety protocols.</p>

- Q: What are the pros and cons of utilizing hydraulic fluid within the system of a building hoist?

- <p>The advantages of using hydraulic fluid in a building hoist include smooth and controlled lifting, which reduces the risk of accidents. It also offers a compact design due to the high power-to-weight ratio of hydraulic systems. Additionally, hydraulic systems are known for their durability and low maintenance requirements. However, there are disadvantages such as the potential for leaks, which can be hazardous and costly to repair. The systems can also be sensitive to temperature changes, which might affect performance. Lastly, hydraulic fluids can be environmentally harmful if not properly managed, posing disposal challenges.</p>

- Q: Is it permissible to use a building hoist for the purpose of lifting hazardous materials?

- <p>A building hoist is typically not designed for lifting dangerous materials. It is meant for the transportation of construction materials and personnel within a building. Lifting hazardous materials requires specialized equipment and procedures to ensure safety. Always refer to the manufacturer's guidelines and local regulations for the appropriate use of hoisting equipment and handling of dangerous materials.</p>

- Q: 6 layer of brick and concrete construction project, have tower crane still need construction elevator?

- 6 floors of brick and concrete construction projects, tower cranes do not need construction elevator. Brick structure refers to the building of the wall of vertical bearing structure, column, etc. By using brick or block masonry, lateral load-bearing beam, reinforced concrete structure is adopted for floor, roof boarding, etc. In other words, the masonry structure is a small amount of reinforced concrete and most brick wall bearing structures. The masonry structure is a kind of hybrid structure, which is composed of brick wall and reinforced concrete beams. Suitable for small width and depth, room area is small, multilayer or low-rise buildings, for load bearing walls can't change, while the frame structure of wall body can be altered.

- Q: What are the primary roles or purposes that a building hoist serves in construction?

- <p>Building hoists, also known as construction hoists, serve several essential functions in construction projects. They are primarily used for the vertical transportation of workers, materials, and equipment within a building under construction. They increase efficiency by reducing the time and effort required to move materials and personnel, ensuring a faster construction process. Hoists also enhance safety by providing a controlled and secure means of vertical transportation, reducing the risk of accidents associated with manual material handling. Additionally, they contribute to the overall project timeline by allowing for simultaneous work on multiple floors, improving the coordination of construction activities.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

- Q: What are the expenses involved in buying and maintaining a building hoist?

- <p>The costs of purchasing and operating a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the model and capacity. Operating costs involve maintenance, which may be around $1,000 to $5,000 per year, and electricity for operation, which can vary based on usage. Additionally, there may be costs for installation, insurance, and potential repairs. Labor costs for operating the hoist should also be considered, as well as costs for compliance with safety regulations. These costs can vary widely based on location, the specific hoist model, and the scale of operations.</p>

Send your message to us

Construction Hoist Safety Device for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords