Brushed Aluminum Trim Strips Newest Aluminium Sheet AA1100 Aluminium

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Tight aluminium boxes can effectively exclude or screen off electromagnetic radiation. The better the conductivity of a material, the better the shielding qualities.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

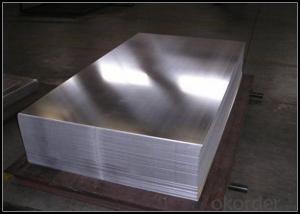

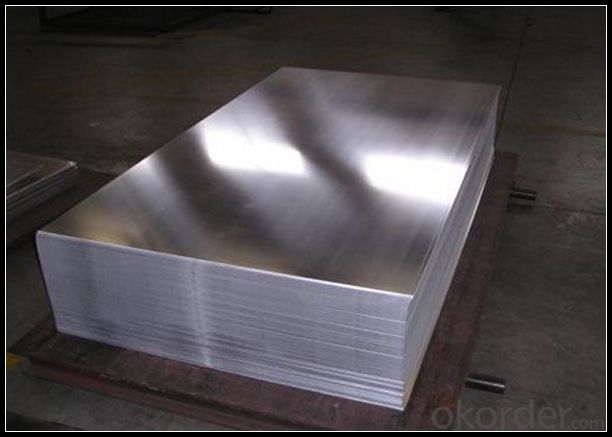

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to use aluminum strips in decorative applications?

- <p>Yes, aluminum strips can be used for decorative purposes. They are lightweight, durable, and available in various colors and finishes, making them suitable for a range of decorative applications. Aluminum strips are often used in interior design for trims, moldings, and accents, as well as in exterior applications such as facades and signage. Their resistance to corrosion and ease of maintenance also make them a practical choice for decorative elements in both residential and commercial settings.</p>

- Q: This question asks for an explanation of the various types of aluminum cladding materials used in construction.

- <p>Aluminum cladding is a popular choice in construction for its durability and low maintenance. The different types include: 1. Aluminum Composite Material (ACM), which is lightweight and consists of two thin aluminum sheets with a non-aluminum core. 2. Aluminum Plate, a thicker and more rigid material used for structural applications. 3. Aluminum Extrusions, which are formed by pushing aluminum through a die to create specific shapes and profiles. 4. Aluminum Coil Coating, where aluminum coils are coated with a protective layer and used for roofing and siding. 5. Anodized Aluminum, which undergoes an electrochemical process to increase its resistance to wear and corrosion. Each type has specific applications and properties, making them suitable for different construction projects.</p>

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: Is it possible to utilize aluminum strips in outdoor settings?

- <p>Yes, aluminum strips can be used for outdoor applications. They are known for their corrosion resistance, making them suitable for outdoor environments where they may be exposed to various weather conditions. Aluminum's durability and lightweight properties also make it a popular choice for outdoor construction and decoration. However, it's important to ensure that the aluminum is properly treated or coated to enhance its resistance to weathering and maintain its appearance over time.</p>

- Q: Is it possible to utilize recycled nails or screws for the installation of aluminum strips?

- <p>Yes, you can use recycled nails or screws to install aluminum strips, provided they are in good condition and compatible with the material. Ensure the recycled fasteners are clean, rust-free, and have no damage that could affect their holding power. It's also important to use the correct size and type of nails or screws suitable for the thickness and type of aluminum strips you are installing. Always follow safety precautions and use appropriate tools to prevent injury.</p>

- Q: Is it possible to recycle aluminum foil along with aluminum strips?

- <p>Yes, aluminum foil can be recycled with aluminum strips. Both are made of aluminum and can be processed together in recycling facilities. It's important to clean and separate them from other materials before recycling to ensure efficient processing. Recycling aluminum products helps conserve resources and reduces energy consumption compared to producing aluminum from raw materials.</p>

- Q: This question asks for an overview of the steps involved in the manufacturing of aluminum components used in vehicles.

- <p>The production process of automotive aluminum parts typically involves several key steps: material selection, design, casting or forging, machining, heat treatment, surface treatment, and quality control. Aluminum is chosen for its lightweight and high strength properties. The design phase involves creating detailed plans for the part. Casting or forging shapes the aluminum into rough forms. Machining refines these forms to precise specifications. Heat treatment enhances strength and durability. Surface treatments protect against corrosion and wear. Finally, quality control ensures each part meets industry standards before it is used in vehicles.</p>

- Q: This question asks if there are any potential health hazards linked to the use of aluminum strips.

- <p>There are some concerns regarding the use of aluminum strips, particularly in the context of cooking utensils and food packaging. Prolonged exposure to aluminum has been linked to potential health risks, including Alzheimer's disease, although the evidence is inconclusive. Aluminum can leach into food, especially in acidic environments, which may lead to increased aluminum intake. However, the FDA and other health authorities have not issued warnings about the use of aluminum cookware or food packaging, as the levels of aluminum typically ingested are considered safe. It's important to note that more research is needed to fully understand the potential health implications of aluminum exposure.</p>

- Q: Is it possible to use aluminum strips for creating electrical connections?

- <p>While it is technically possible to use aluminum strips to make electrical connections, it is not generally recommended due to several reasons. Aluminum has a higher electrical resistance compared to copper, which is the standard material for electrical wiring. It is also more prone to corrosion and can form aluminum oxide, which is an insulator, leading to poor connections over time. Additionally, aluminum expands and contracts more than copper with temperature changes, which can cause connections to loosen. For reliable and safe electrical connections, copper or other approved materials should be used.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a wall.

- <p>To install aluminum strips on a wall, first measure and mark the area where you want to install the strips. Clean the wall surface thoroughly to ensure proper adhesion. Apply a strong adhesive or use wall anchors and screws, depending on the weight and size of the strips. Align the first strip at the bottom and press firmly to secure it. Use a level to ensure it's straight. Attach subsequent strips side by side, maintaining a consistent gap if desired. Smooth out any bubbles or wrinkles with a putty knife. Once all strips are installed, allow the adhesive to cure according to the manufacturer's instructions before handling.</p>

Send your message to us

Brushed Aluminum Trim Strips Newest Aluminium Sheet AA1100 Aluminium

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords