Hot Rolled Steel Sheets304L,Stainless Steel Coils 304 From China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

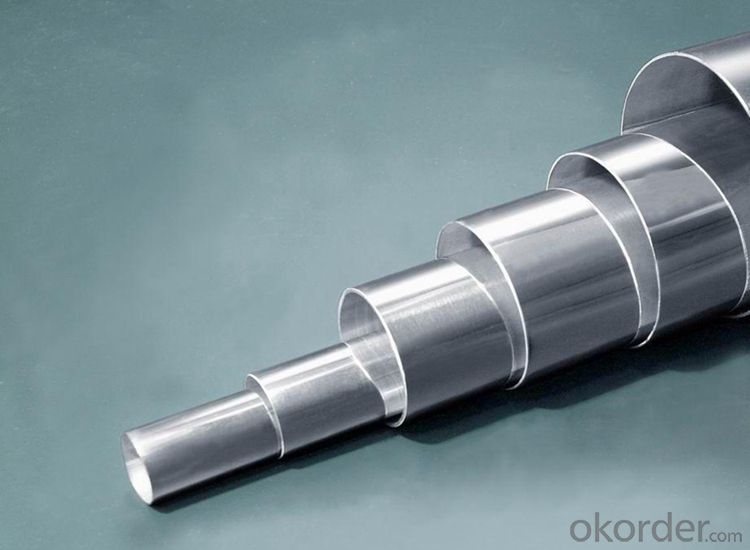

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:Can stainless steel sheets be used in the medical industry?

- Yes, stainless steel sheets can be used in the medical industry. Stainless steel is a popular material choice in the medical field due to its excellent corrosion resistance, high strength, and durability. It is commonly used for a variety of applications, including medical instruments, surgical tools, dental equipment, implants, and medical equipment. Stainless steel sheets are also easy to clean and sterilize, making them ideal for maintaining hygienic conditions in medical environments. Additionally, stainless steel is biocompatible, meaning it is compatible with human tissues and does not cause any adverse reactions, making it a safe choice for medical applications. Overall, stainless steel sheets are highly suitable for use in the medical industry due to their numerous beneficial properties.

- Q:Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular material choice for medical equipment due to its corrosion resistance, durability, and easy maintenance. It is commonly used in surgical instruments, medical devices, hospital furniture, and other medical applications.

- Q:Can stainless steel sheets be used for hygienic applications?

- Yes, stainless steel sheets can be used for hygienic applications. Stainless steel is known for its non-porous surface, resistance to corrosion, and ability to withstand high temperatures, making it ideal for industries such as food processing, pharmaceuticals, and healthcare where cleanliness and hygiene are essential. The smooth surface of stainless steel sheets prevents the growth of bacteria, making it easy to clean and maintain a hygienic environment.

- Q:Are stainless steel sheets suitable for architectural wire mesh?

- Architectural wire mesh benefits greatly from the use of stainless steel sheets. This material is a popular choice in architectural applications because of its many advantageous properties. Firstly, stainless steel is exceptionally durable and resistant to corrosion, making it perfect for both indoor and outdoor use over long periods of time. This corrosion resistance is particularly important for architectural wire mesh, as it ensures the material will maintain its integrity and appearance over time. In addition to this, stainless steel sheets offer excellent strength and stability, making them capable of withstanding the various stresses and strains that architectural wire mesh may encounter. This is crucial in applications where the mesh needs to support structural loads or provide security. Furthermore, stainless steel comes in different grades, allowing for customization to meet specific project requirements in terms of strength and flexibility. Stainless steel sheets also have a significant aesthetic appeal. Their sleek and modern appearance complements contemporary architectural designs and adds an elegant touch to any space. Moreover, stainless steel can be finished in different ways, such as brushed, polished, or coated, to achieve the desired visual effect. Lastly, stainless steel is a sustainable choice for architectural wire mesh. It is 100% recyclable, reducing environmental impact and supporting green building initiatives. Additionally, its long lifespan and low maintenance requirements contribute to its sustainability, minimizing the need for frequent replacements or repairs. In conclusion, stainless steel sheets are highly suitable for architectural wire mesh due to their durability, corrosion resistance, strength, aesthetic appeal, and sustainability. Architects and designers prefer them for their versatility in meeting various project requirements and their ability to create visually stunning and functional wire mesh installations.

- Q:Are stainless steel sheets suitable for medical implants?

- Stainless steel sheets are indeed appropriate for medical implants. This is because stainless steel, which is commonly utilized in medical implants, possesses desirable qualities such as resistance to corrosion, strength, and biocompatibility. These sheets can be shaped and sized in various ways, making them adaptable for different types of implants. Moreover, stainless steel has been extensively researched and proven to be safe for long-term implantation in the human body. In addition, it is cost-effective when compared to alternative implant materials. However, it is crucial to emphasize that the particular grade of stainless steel and the surface finish play pivotal roles in determining its suitability for medical implants. The grade of stainless steel must meet biocompatibility and corrosion resistance standards, while the surface finish must be smooth to minimize the risk of infection and encourage proper tissue integration. In conclusion, stainless steel sheets are a dependable and widely utilized material for medical implants.

- Q:Can stainless steel sheets be painted?

- Painting stainless steel sheets is indeed possible. However, it is crucial to adequately prepare the surface beforehand to ensure the paint adheres well and maintains its quality over time. Thoroughly cleaning and degreasing the stainless steel surface is essential, along with removing any existing rust or oxidation. To facilitate adhesion, it is advisable to use a primer specifically designed for metal surfaces, followed by a high-quality paint suitable for metal. Additionally, applying a clear coat or sealer is recommended to protect the paint finish. It is important to note that regular upkeep may be necessary to preserve the appearance of the painted stainless steel sheets, as the paint may chip or wear with time.

- Q:What are the different sheet sizes available for stainless steel?

- Stainless steel sheets come in a variety of sizes to suit different applications and industry requirements. The most common sheet sizes for stainless steel are 4 feet by 8 feet (48 inches by 96 inches) and 4 feet by 10 feet (48 inches by 120 inches). These sizes are widely used in construction, manufacturing, and fabrication industries. However, stainless steel sheets are also available in other sizes depending on the specific needs of the project. Some suppliers offer custom cutting services, allowing customers to order sheets in non-standard dimensions. This flexibility in size options ensures that stainless steel sheets can be tailored to fit various applications, from small-scale projects to large industrial installations. Moreover, the thickness of stainless steel sheets can vary significantly. Standard thicknesses range from 0.4 millimeters to 12 millimeters, but thicker or thinner sheets can be manufactured upon request. Different thicknesses are selected based on the strength and durability required for a particular application. Ultimately, the availability of different sheet sizes for stainless steel ensures that customers have the flexibility to choose the most suitable dimensions for their specific project needs.

- Q:What is the general width range of stainless steel sheet? What are the common widths?

- According to the agreement can be scheduled to open, usually to add money, commonly used thin 3mm below the general specifications commonly used, 1000*20001219*2438, 3mm or more commonly used specifications 1500*6000.

- Q:How do you remove adhesive residue from stainless steel sheets?

- To effectively eliminate adhesive residue from stainless steel sheets, the following steps can be followed: 1. Commence by delicately scraping off as much of the residue as possible using a plastic scraper or your fingernail. Exercise caution to avoid scratching the stainless steel surface. 2. Subsequently, moisten a soft cloth with warm water and a mild detergent or dish soap. Employ gentle circular motions to scrub the adhesive residue. Refrain from using abrasive cleaners or scrub brushes as they have the potential to harm the stainless steel finish. 3. If the adhesive residue persists, consider utilizing a non-abrasive cleaner specifically designed for stainless steel. Apply a small quantity of the cleaner to a soft cloth and gently rub the residue until it detaches. 4. In the case of tenacious adhesive residue, a paste can be concocted by combining baking soda and water. Apply the paste to the affected area and allow it to sit for a few minutes. Subsequently, utilize a soft cloth to gently scrub the residue in circular motions. 5. Thoroughly rinse the stainless steel sheet with warm water to eliminate any remaining residue or cleaner. 6. Finally, employ a clean, soft cloth to dry the surface, thereby preventing water spots and streaks. It is important to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet prior to applying it to the entire surface. This precautionary measure ensures that no damage or discoloration occurs.

- Q:Can stainless steel sheets be used for signage?

- Stainless steel sheets are indeed capable of serving as signage. This material possesses durability and longevity, being highly resistant to corrosion, thereby rendering it suitable for both indoor and outdoor applications. Its sleek and contemporary appearance contributes to its popularity across various signage types, encompassing company logos, directional signs, nameplates, and even expansive outdoor billboards. The flexibility of stainless steel sheets allows for easy customization through cutting, engraving, or laser-etching, thereby offering a vast array of creative possibilities. Furthermore, the choice of stainless steel signage often stems from its ability to withstand adverse weather conditions, UV rays, and acts of vandalism, thereby preserving the integrity and legibility of the signage for numerous years.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Sheets304L,Stainless Steel Coils 304 From China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords