high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

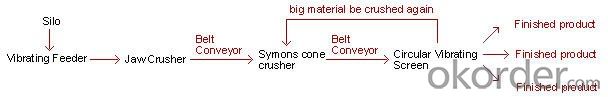

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q:Want to find an accurate explanation of jaw crusher, which is a kind of crushing machine.?

- If okorder /

- Q:its metal/rock not rap! a small part of the song was i climbed to the top of the empire state building jumped off and landed on my headi jumped up and did a f*cking little dance just to prove i wasnt dead yet!im not positive on the words but i know im close!i thought it was Soulhat?!

- was okorder /

- Q:What does "mantle" mean in the crusher? Which part is it?

- It's shell. A part of a layer outside a crusher.

- Q:I am 17 will be 18 in july and i wanted to know can a 17 year old be a stocker for walmart? because i know they have that box crusher which u cant use unless ur 18 but i heard u can put boxes somewhere and someone else will crush them..is this true and if you have worked or do work as a stocker how is it? Besides crappy...cause most jobs are...

- be careful. my uncle went to jail for stocking. he just wouldn't leave her alone.

- Q:It has the part, quot;Boom its on we gonna rock your domequot;

- only thing I can think of is by ying yang twinz-whats happening BOOM!! it's on, ***** ***** we'll rock yo' dome BOOM!! ***** what's happnin'? (WHAT?!) BOOM!! ***** what's happnin'? (WHAT?!) BOOM!! it's on, ***** ***** we'll rock yo' dome BOOM!! ***** what's happnin'? (WHAT?!) BOOM!! ***** what's happnin'? (WHAT?!) sorry I couldn't help

- Q:Where did Dr.Crusher have to go ?

- During the second season of STNG, Dr. Pulaski comes on board the Enterprise as new Chief Medical Officer while Dr. Crusher leaves to become the head of Starfleet Medical. This is mentioned during the episode, The Child.

- Q:Jar Jar was in the Star Wars prequels, and caused countless fans to fantasize about creative ways of killing him.Wesley Crusher was in Star Trek: The Next Generation, and caused countless fans to fantasize about Captain Picard shooting him out into space and letting Worf use him as target practice.Which did you find more annoying?

- The Crusher

- Q:diadvantages of jaw crusher?

- Introduction Jaw Crusher is important equipment in mineral processing fields. It is mainly used for crushing large bulk mineral materials into small pieces so as to finely grind by ball mill. It is widely used to crush all kinds of rough-crushing or middle-crushing ore and rock whose compressive strength is less than 320Mpa in mineral, smelting, construction, highway, railway, hydraulic conservancy and other industries. Jaw Crusher is mainly made up of the following parts: frame components, eccentric shaft, jaw plate, connecting rod, adjusting components, latching spring and so on . Hongtong Technology designed a series of dressing equipment according to the ore properties based on the mineral processing flowsheet. It has many advantages such as high-efficiency, low malfunction rate and wide application ranges. A set of dressing equipments include Raw crusher, Hammer crusher, Dry and wet ball mill, Energy-saving cone ball mill, MQG-tube mill, Ceramic ball mill, Magnetic separator, Flotation machine, Screw grader, Cylinder screen, High-frequency screen, Pendulum and chute feeder, Mineral agitation barrel and H-rotary dryer. Characteristics of Jaw Crusher: 1. Large crushing ratio 2. Uniformed granularity particles 3. Simple structure 4. Reliable operation 5. Easy maintenance 6. Low operating cost

- Q:Cant really go into more detail on this im afraid. Im just really stumped and have been thinking about this all day.

- I don't think that there is a car out there that can not go over speed bumps , if they could not go over the speed bumps the car would not be allowed to pass inspection to be able to sell , unless it was a race car so you should be fine !

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high efficiency jaw crusher used for mineral PE 600*750

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products