HDPE Uniaxial Geogrid with High Strength Manufactury

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

CMAX Uniaxial geogrid are manufactured by a process of extruding, punching, heating and longitudinal stretching. It is made of high density polythylene and they are chemically inert, unaffected by the U.V. rays and fully resistant to aging in the soil environment.

Performance:

High Strength, good flexibility, anti-aging, resisting acid and alkaline.

Applications:

Make reinforcement for various kinds of soft soil foundation enhance and improve bearing ability of the roadbed, make reinforcement for retaining wall, steep slope, dam and bridge abutment under stress status for long term thus to improve quality and prolong service life of the project.

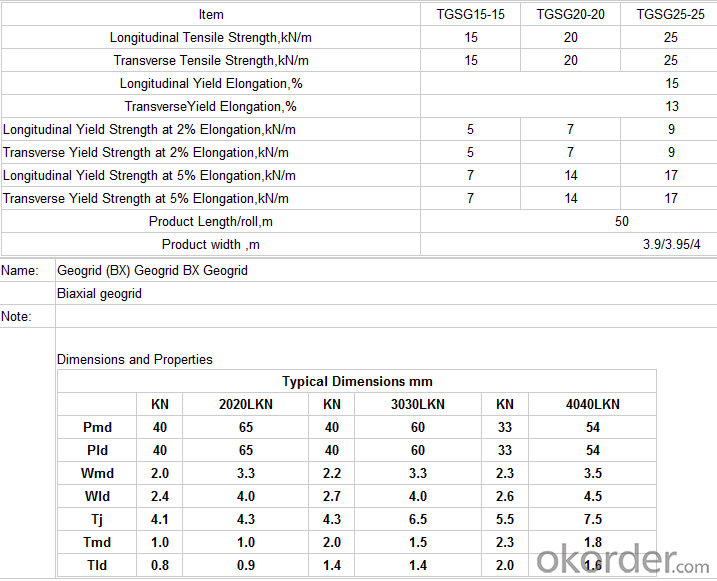

Specification:

Packing:

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

- Q:What are the factors that influence the design and selection of geogrids for reinforcement?

- There are several factors that influence the design and selection of geogrids for reinforcement. These include the type and characteristics of the soil, the specific application or project requirements, the anticipated loads or stresses on the geogrid, the desired design life and durability, and cost considerations. Additionally, factors such as installation conditions, site constraints, and environmental conditions may also play a role in determining the appropriate geogrid design and selection.

- Q:What is the width of glass fiber grating 100cm

- 1 meters wide,???? Is there anything to ask

- Q:How to connect the geogrid with the panel in the reinforced earth retaining wall?

- When the geogrid is laid in the curve and the corner, the adjacent earthwork grid is currently used in the reinforced earth retaining wall of the assembled panel, and the common wall of the assembled panel module will have gaps or overlaps (see Figure 1). For the outward bending of the geogrid, there are different forms such as rectangle, hexagon, shape, L shape and groove shape. Panel module will appear at the corner of the gap,In order to ensure the continuity of the reinforced soil, laying in the void design based on the engineering environment need to be flexible, prefabricated into various shapes, can provide the same type of geogrid small pieces of good, and cover all the reinforced area; for bend shop visual effect; can also use color cement, add art wall. No panel reinforcement design of geogrid, in the corner there will be some overlap in geogrid, geogrid reinforced earth retaining wall is also called anti package type or wrap-reinforcedearth retaining wall, the wall is made of mesh bags to fill the overlap coefficient of friction will be reduced, must be laying a layer of 10mm ~ 20mm thick the soil geogrid anti package into each layer of geogrid is a special connecting rod is connected with the shape of the coarse sand layer, separate the two layer of Geogrid to ensure friction resistance. As a whole, the mesh bag filling has been mixed for local growth of grass and shrub seeds, seeds, after months of growth after the formation of green ecological wall. The utility model not only protects the safety of the geogrid, but also beautifies the environment of the retaining wall project.

- Q:Can geogrids be used in erosion control blankets?

- Yes, geogrids can be used in erosion control blankets. Geogrids are commonly used as reinforcement materials in erosion control applications to provide additional strength and stability to the blanket, preventing soil erosion and promoting vegetative growth.

- Q:What are the different installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, trenching and backfilling, and mechanical installation. Direct placement involves laying the geogrid directly on the subgrade or soil surface and then covering it with a layer of aggregate. Trenching and backfilling method involves excavating a trench, placing the geogrid in the trench, and then backfilling it with soil or aggregate. Mechanical installation methods use specialized equipment, such as a geogrid installation machine, to unroll and place the geogrid in the desired location. The chosen installation method depends on factors such as the application, site conditions, and specific project requirements.

- Q:What is the market price of the geotechnical grid in 2017?

- (4) the first layer of geogrid paved, began to fill with second layers of 0.2m in thick sand (coarse), the method of sand transport to the site: car unloading to the subgrade side, then put forward to push the bulldozer, within 2 meters on both sides of the subgrade filling after 0.1M, the first layer of geogrid fold up and then fill in 0.1 meters in the sand (coarse), from both sides to the middle filling and advance, prohibit all machinery without filling (coarse sand) of Geogrid on traffic operation, it can guarantee the geogrid is smooth, does not play drums, do not wrinkle, stay in the second layer (coarse) after the formation of sand, the level of measurement, to prevent uneven filling thickness, leveling and correct use of vibratory roller 25T static pressure two times.

- Q:Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are commonly used to stabilize soil and prevent erosion, making them an effective solution for protecting shorelines from wave action and water currents. They can be installed in various configurations, such as beneath riprap or as a reinforcement layer for soil, to enhance the stability and longevity of shoreline protection measures.

- Q:How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by reinforcing and stabilizing soil, thereby minimizing the need for excessive excavation and the use of additional materials such as stone or concrete. This reduces the demand for natural resources like aggregates, sand, and gravel, leading to a more sustainable and eco-friendly construction process.

- Q:Can geogrids be used in reinforcement of embankments on expansive clays?

- Yes, geogrids can be used in the reinforcement of embankments on expansive clays. Geogrids are commonly used in geotechnical applications to enhance the stability and strength of soil structures. By incorporating geogrids into the embankment design, they can help distribute loads, reduce settlement, and provide reinforcement against lateral movement. This is particularly beneficial when dealing with expansive clays, which are prone to swelling and shrinkage. The geogrids can effectively restrain the clay's movement and prevent potential damage to the embankment.

- Q:Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used in civil engineering and construction projects to improve the stability and strength of soil-lime mixtures. They provide additional tensile strength, prevent soil erosion, and enhance the load-bearing capacity of the mixture. By adding geogrids, the performance and durability of soil-lime mixtures can be significantly improved.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Uniaxial Geogrid with High Strength Manufactury

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords